Process and device for coupling drying of high temperature steel slag and sludge

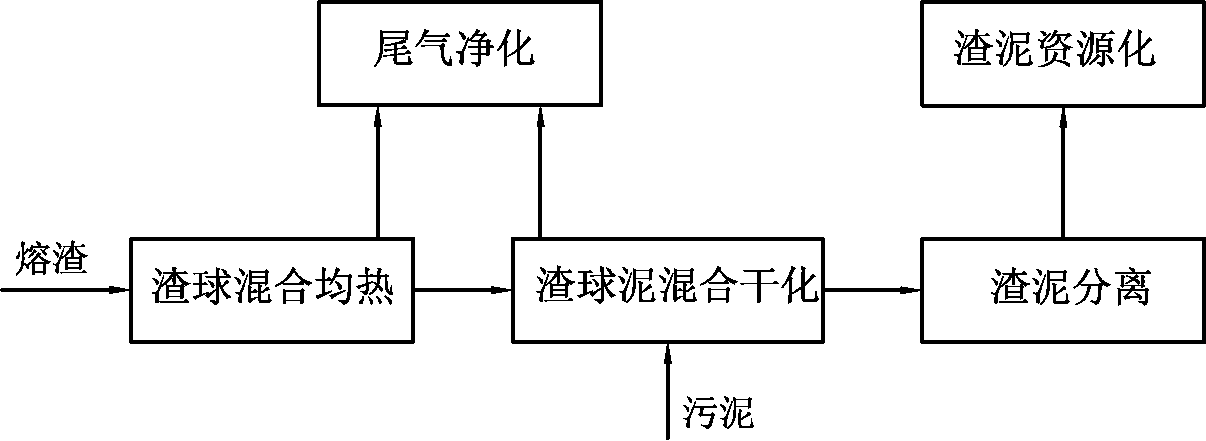

A technology for sludge and steel slag, which is applied in the direction of sludge treatment through temperature control, heating device, dewatering/drying/concentrating sludge treatment, etc., which can solve the problem of high sludge drying cost, large energy consumption and sludge drying cost. High level and other problems, to achieve the effect of saving sludge treatment costs, saving cooling water, and stabilizing continuous sludge drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

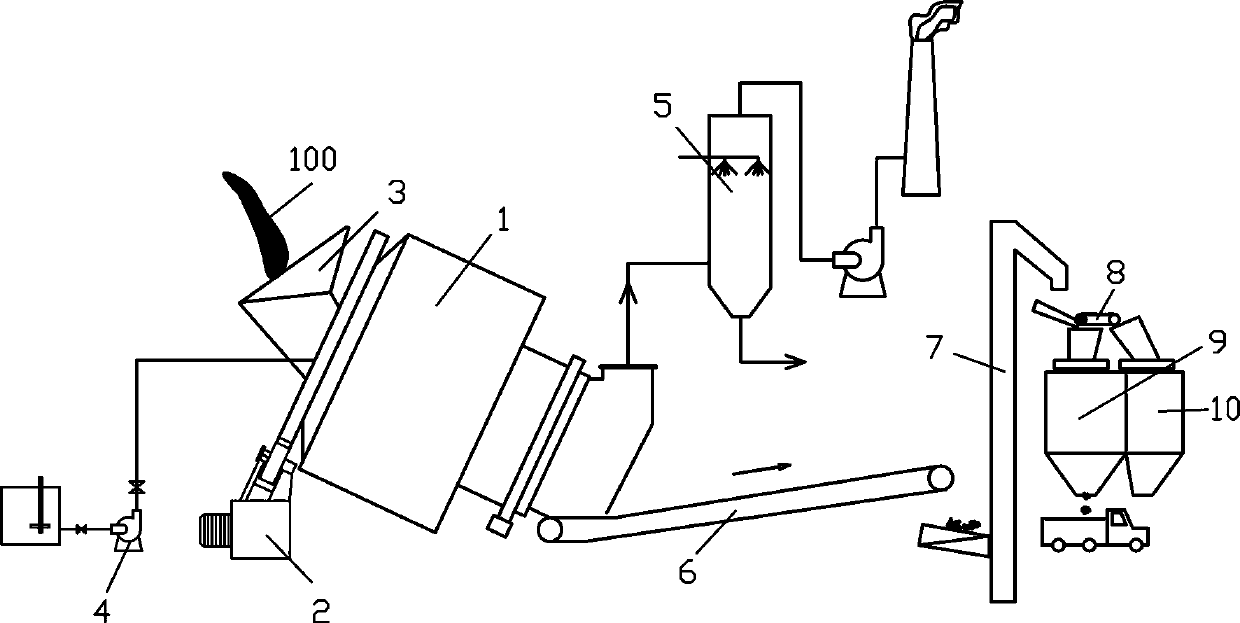

[0059] The shot mixer is a rotating container that can hold 50 tons of steel balls. When high-temperature slag, especially metallurgical slag, is fed into the rotating slag ball mixer by the feeding device, the heat of the slag is quickly captured by the rolling steel balls in the slag ball mixer, and the temperature drops instantly. When the slag temperature is lower than 1000°C, the molten slag is completely solidified and has a certain degree of brittleness. The solidified slag is broken into small particles under the action of the rotation of the slag ball mixer, the rolling impact of the steel ball and its own thermal stress. The steel balls are further mixed and heat-transferred to achieve uniform mixing and a near thermal equilibrium state at 300-800°C. The specific temperature varies with the amount of slag added. For example, when adding 10 tons of 1400°C slag at one time, the equilibrium temperature can be controlled at 600°C Left and right, so as to realize the mixi...

Embodiment 2

[0063] The steel slag treatment process of a steel plant is combined with the OG sludge drying process to form a comprehensive coupling process of slag treatment and sludge drying. A single slag processing device processes 180,000 tons of high-temperature steel slag at 1400°C per year. During the process of processing steel slag, OG mud with a moisture content of more than 80% is pumped into the slag ball mixer, and the high-temperature steel slag is cooled by using the water in the OG mud. Sensible heat drying of steel slag, the ratio of slag / mud entering the slag ball mixer is set to 2:1; after 3 to 5 minutes of mixing and stirring, the steel balls, slag, and mud are fully heat-exchanged and dried, and the steel balls The steel slag and steel slag are cooled to about 150°C, and the sludge is dried to a moisture content of about 20%; the steel slag and dried sludge after sufficient heat exchange are continuously released from the steel slag treatment device, and are separated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com