Tapered bush part processing auxiliary device and use method

A technology of tapered bushings and auxiliary devices, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor accuracy and difficult processing of hammer-shaped bushing parts, so as to reduce the production cycle and reduce the processing time. Cost, effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, the present invention will be further described:

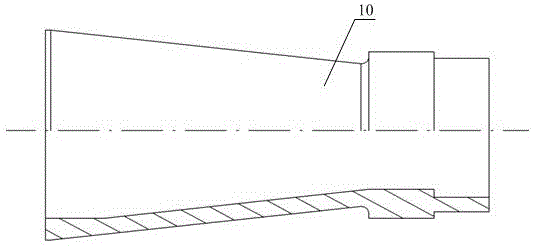

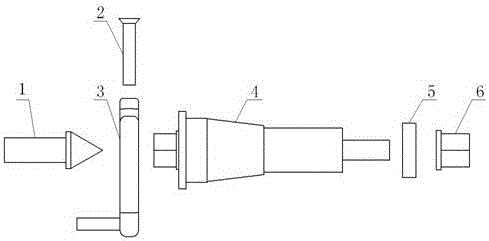

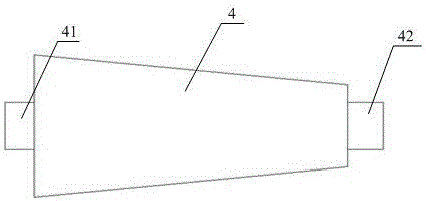

[0022] see attached figure 1 to attach Figure 5 , an auxiliary device for processing tapered bushing parts, comprising a dead thimble 1, a set screw 2, a heart-shaped jacket 3, a mandrel 4, a snap washer 5 and a hex nut 6; the fixed screw 2 connects the heart-shaped jacket 3 with the The mandrel 4 is fixed; the tapered bushing part 10 fits on the mandrel 4, and the tapered bushing part 10 is fixed on the mandrel through the hex nut 6 and the locking washer 5 on axis 4.

[0023] A method for using a processing auxiliary device for tapered bushing parts, comprising the following steps:

[0024] Step 1: Processing the inner shape of the tapered bushing part 10;

[0025] Step 2: fit the tapered bushing part 10 on the mandrel 4 to ensure the positioning, then install the snap washer 5 and the hexagon nut 6, and tighten the hexagon nut 6;

[0026] Step 3: Fix the chicken he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com