Sand mold printing equipment and printing method

A technology of printing equipment and casting molds, which is applied in the direction of casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of slow printing speed, achieve the effects of increasing molding speed, avoiding excessive curing agent content, and shortening printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

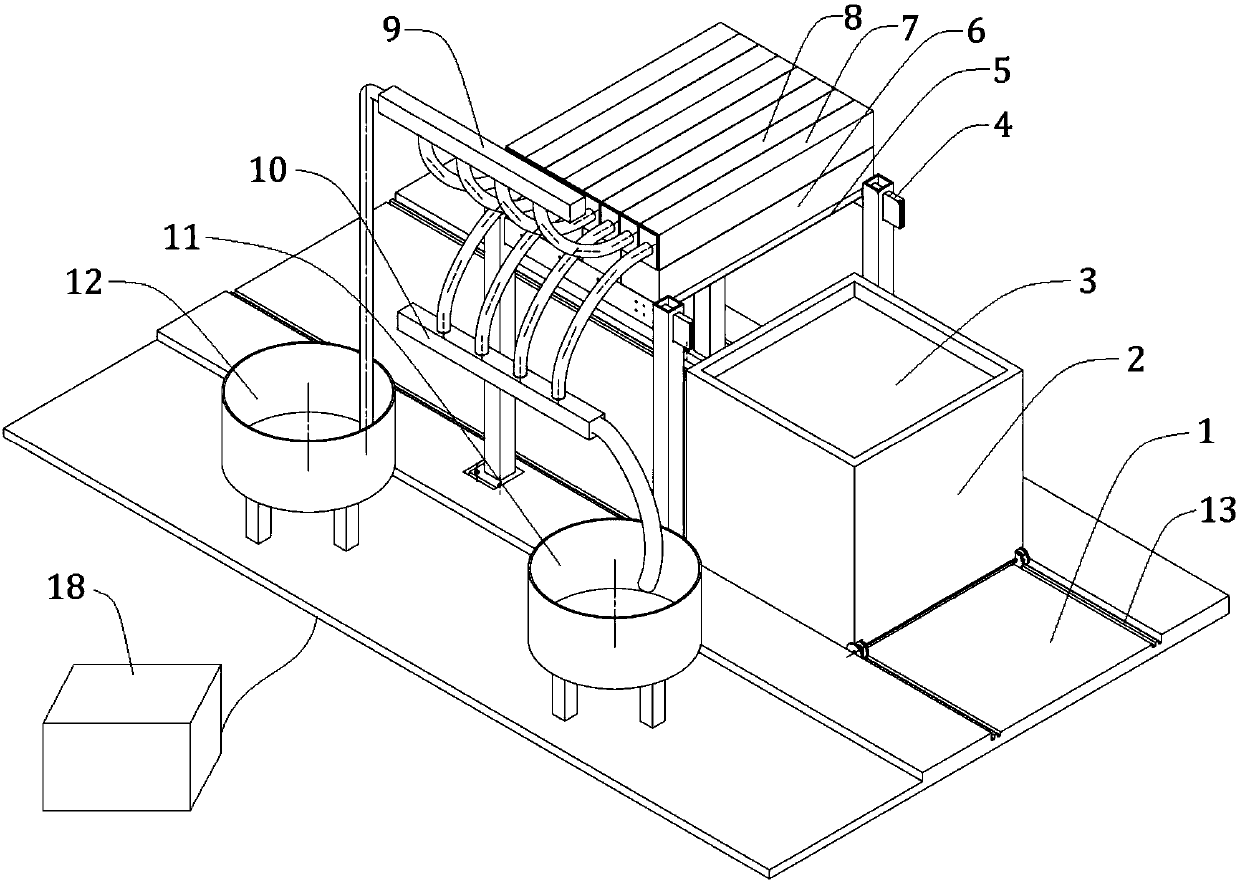

[0031] Such as figure 1 As shown, this embodiment includes: base 1, forming box car 2, blanking support 4, selective paving mechanism 5, blanking mechanism 6, molding material upper hopper 7, auxiliary molding material upper hopper 8, auxiliary molding material The conveying mechanism 9, the molding material conveying mechanism 10 and the control unit 18, wherein: the base 1 is provided with a guide rail 13, the printing platform 3 is movable up and down in the forming box car 2, the forming box car 2 is movably connected with the guide rail 13, and the blanking support 4 Erected on the top of the guide rail 13 and fixedly connected with the base 1, the selective laying mechanism 5 and the blanking mechanism 6 are fixed on the blanking support 4 in sequence from bottom to top, and the molding material upper hopper 7 and the auxiliary molding material upper hopper 8 Alternately arranged on the blanking mechanism 6, the auxiliary molding material conveying mechanism 9 and the mo...

Embodiment 2

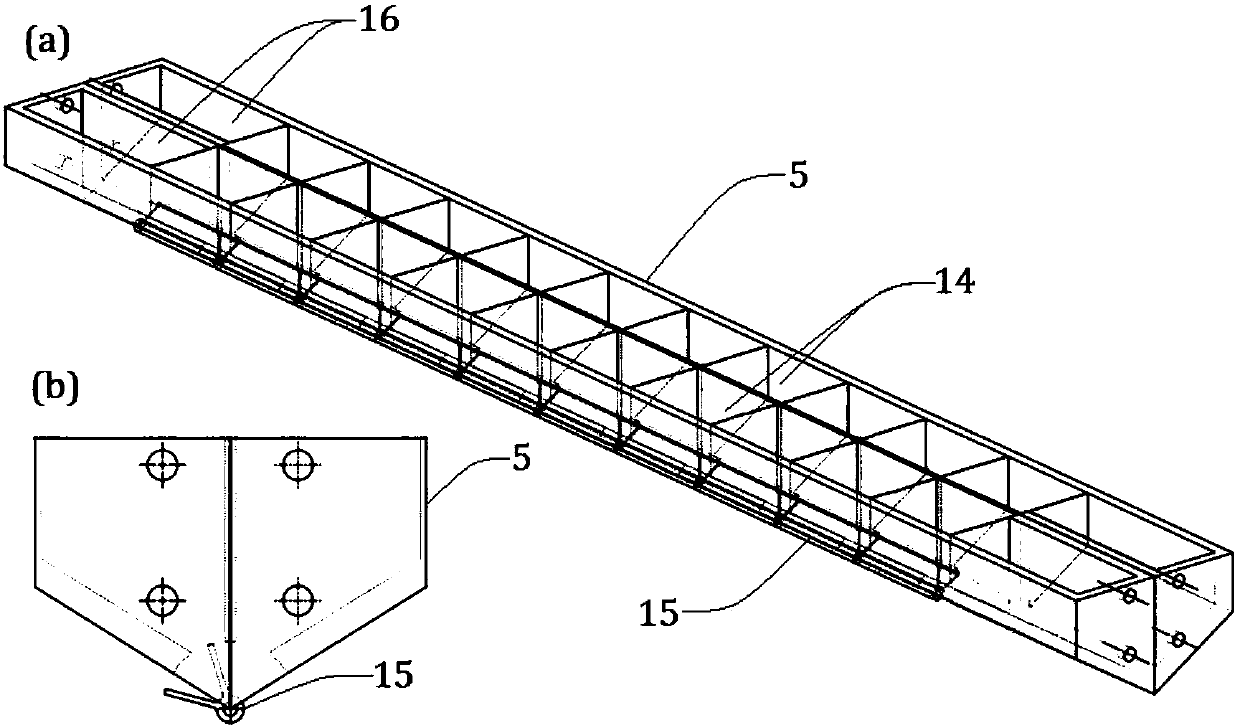

[0046] The difference from Example 1 is that, as image 3 As shown, the selective paving mechanism 5 is wide at the top and narrow at the bottom, and the bottom is wedge-shaped and provided with convex nozzles 17. The nozzle switch 15 is a linear motor switch and is alternately arranged on both sides of the convex nozzles 17; When the nozzle switch 15 is working, it can block any side of the convex nozzle 17 to realize the falling of the material on the other side, and then realize the selective laying of the molding material and the auxiliary molding material.

Embodiment 3

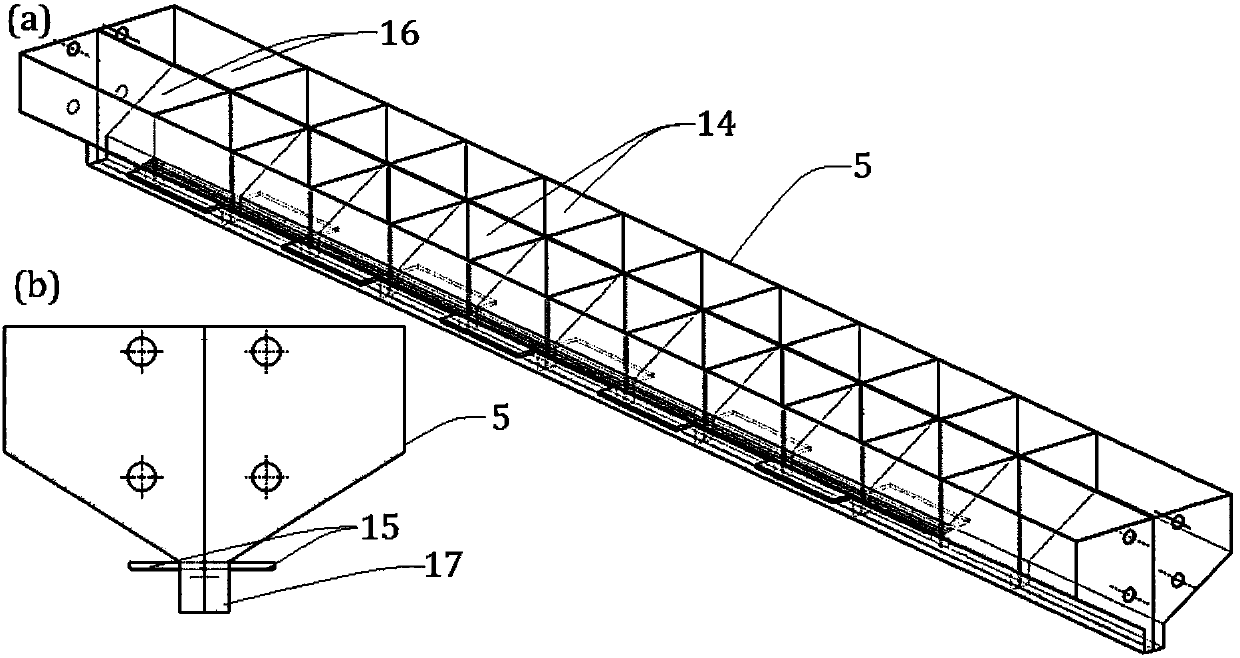

[0048] The difference from Example 1 is that, as Figure 4 As shown, the selective paving mechanism 5 is provided with a follow-up nozzle switch 15, and the follow-up nozzle switch 15 can move back and forth in the longitudinal direction as a whole; while performing horizontal scanning and laying, it can dynamically control the forming according to the forming requirements. Material and auxiliary molding material blanking range; if the follow-up nozzle switch 15 is closed, the auxiliary molding material will drop, otherwise the molding material will drop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com