Automatic material taking device and material taking method for J53-300T friction press

A friction press, automatic reclaiming technology, applied in packaging, conveyors, conveyor objects, etc., can solve the problems of poor working environment, unfavorable health of workers, and high labor intensity of workers, so as to improve the working environment and save money. Manual, solve the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

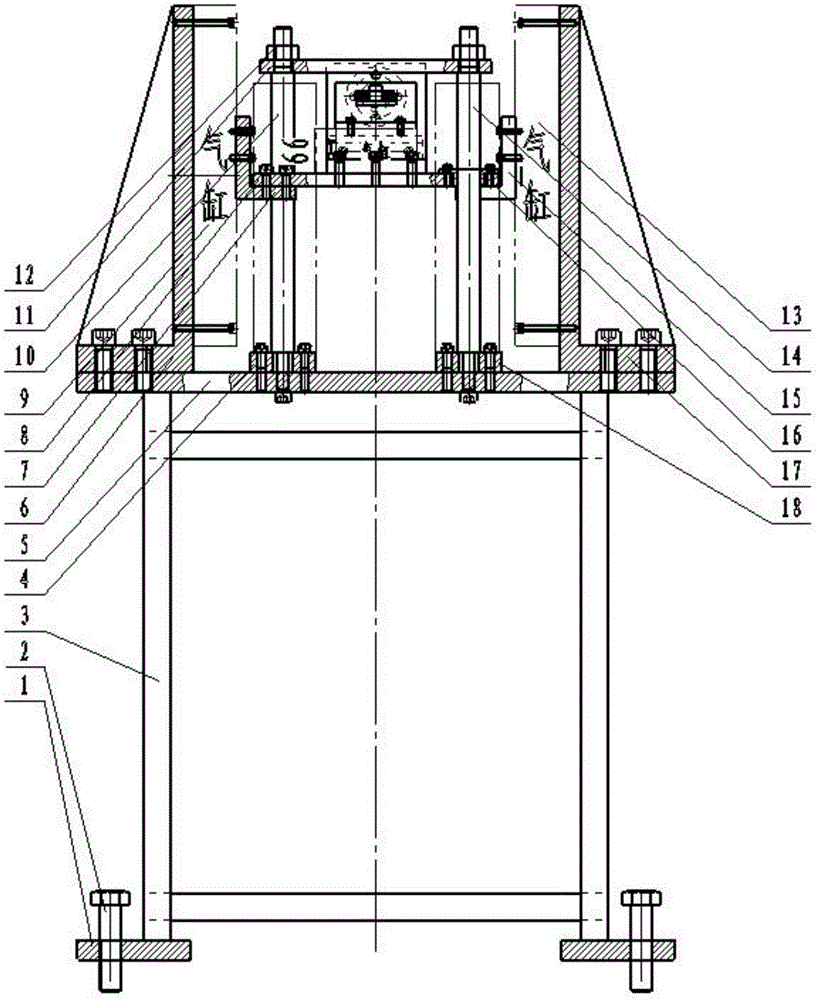

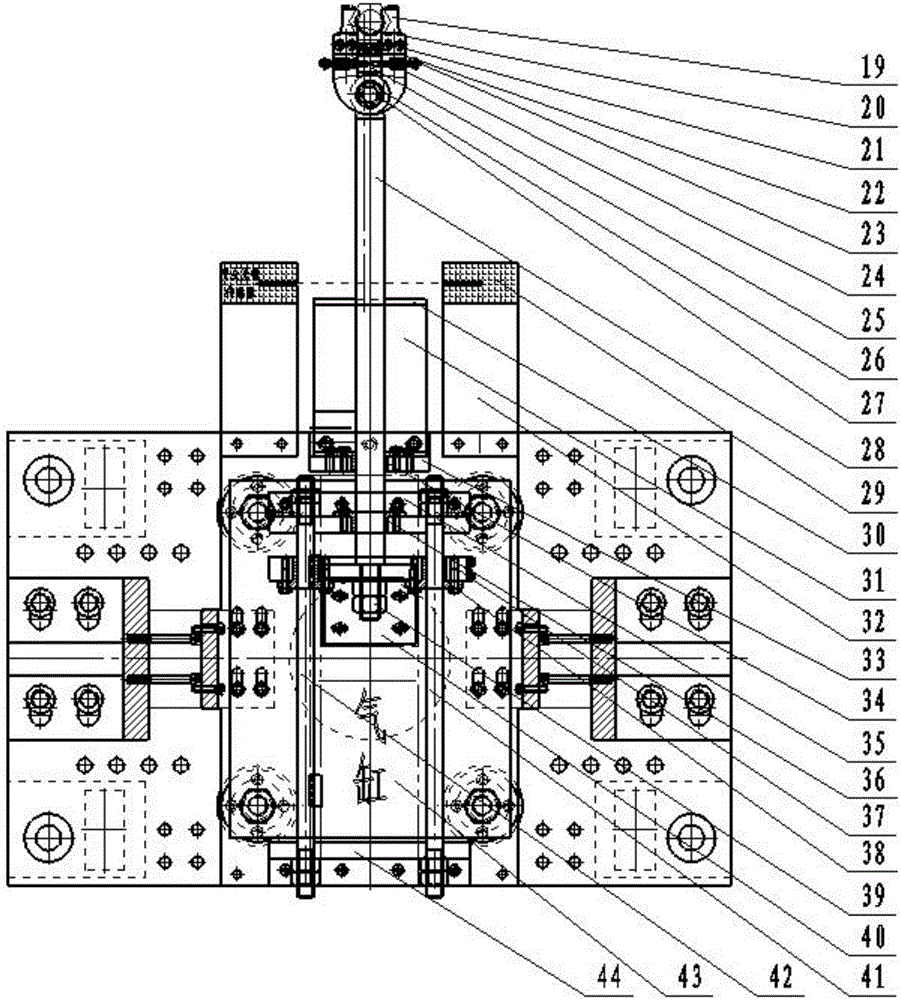

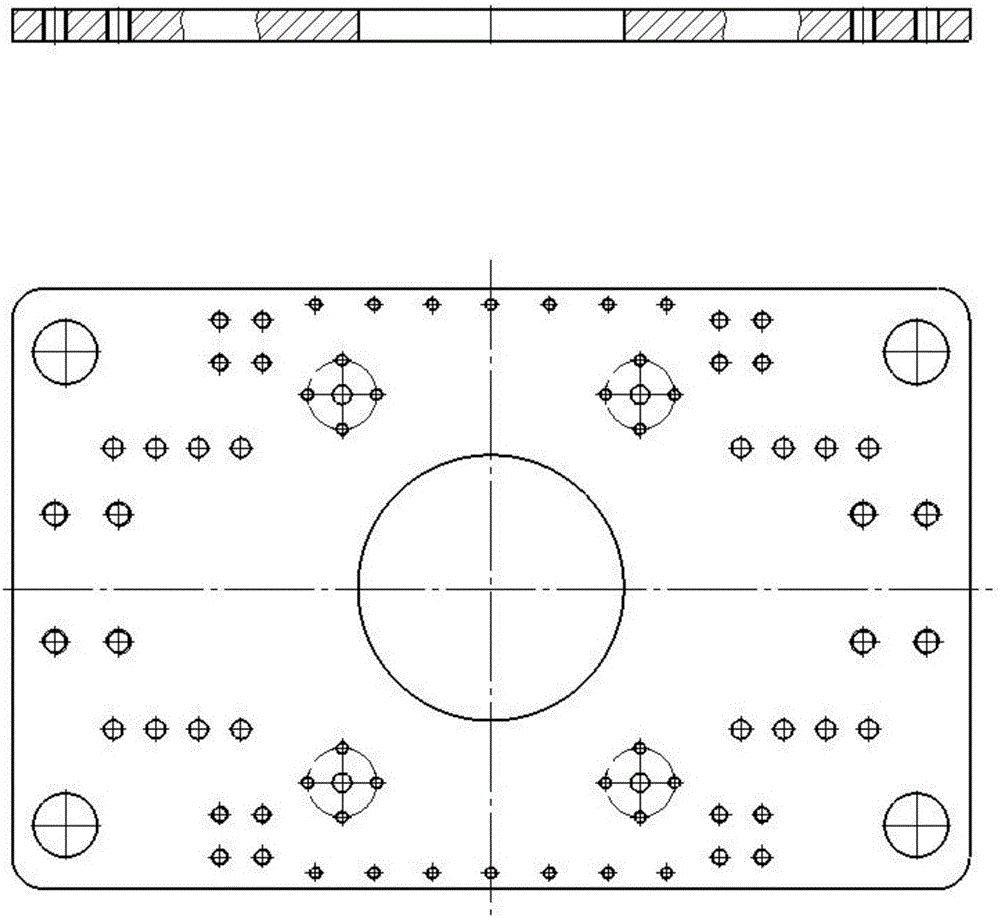

[0025] A J53-300T friction press automatic feeding device, such as figure 1 and figure 2 As shown, it includes: height adjustment plate 1, height adjustment bolt 2, bracket 3, first base 4, bottom plate 5, left cylinder support 6, left L-shaped connecting plate 7, movable plate 8, left cylinder 9, first guide Rod 10, fixed plate 11, hex nut 12, right cylinder 13, second guide rod 14, right L-shaped connecting plate 15, first copper sleeve 16, right cylinder support 17, second base 18, right jaw 19, Left jaw 20, middle jaw 21, right turning piece 22, double-ended stud 23, cylindrical helical compression spring 24, left turning piece 25, second copper sleeve 26, threading pin 27, telescopic rod 28, safety grating sensor 29 , limit plate 30, first adjustment plate 31, second adjustment plate 32, guide seat 33, third copper sleeve 34, front support 35, fourth copper sleeve 36, guide plate 37, fifth copper sleeve 38, hexagonal Nut 39, push plate 40, third guide rod 41, fourth gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com