Furnace wall gun swinging device

A swing device and furnace wall gun technology, applied in the field of metallurgy, can solve the problems of low carbon spraying slagging efficiency, limited cutting scrap steel, small heating range, etc., and achieve the effects of shortening the smelting cycle, saving the cost of steel per ton, and facilitating maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

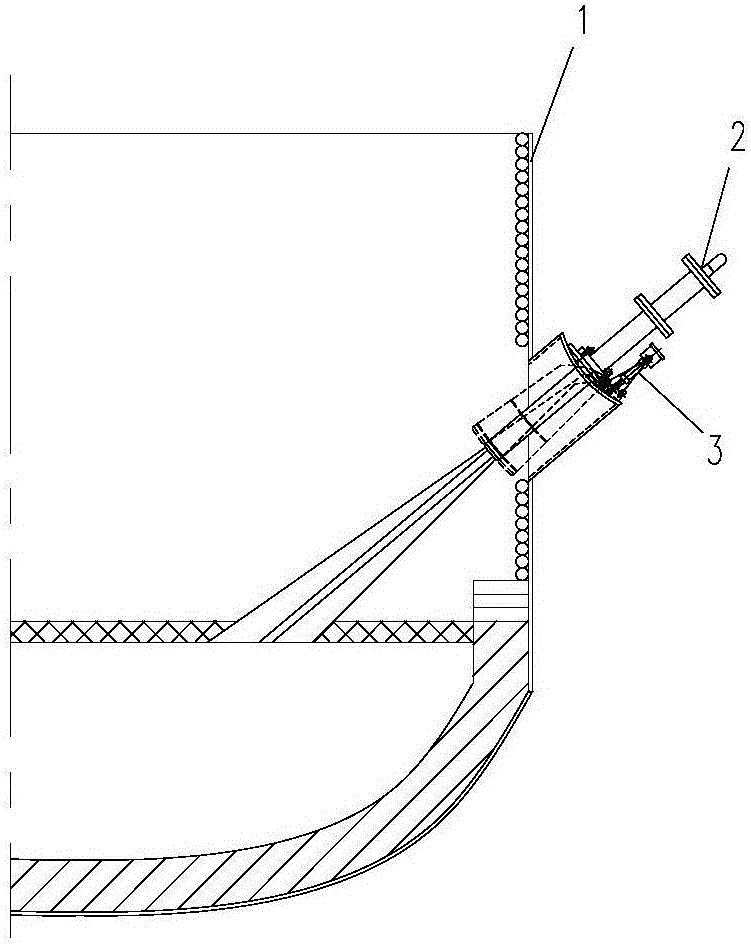

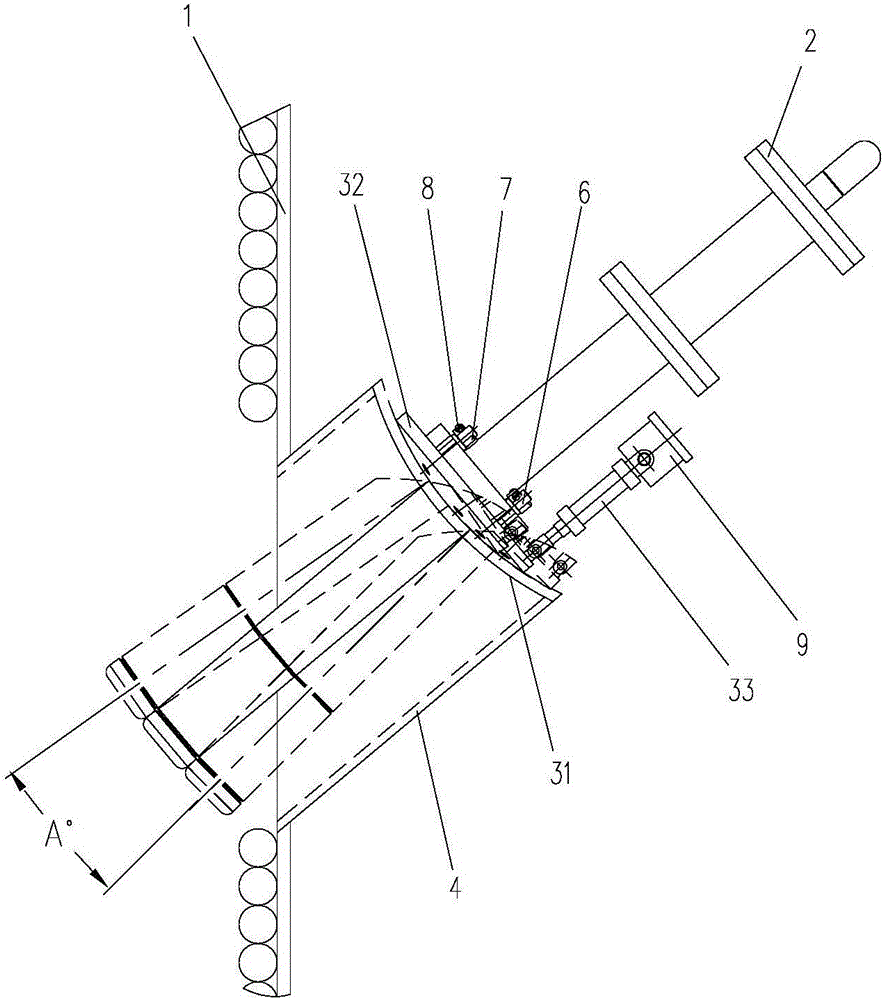

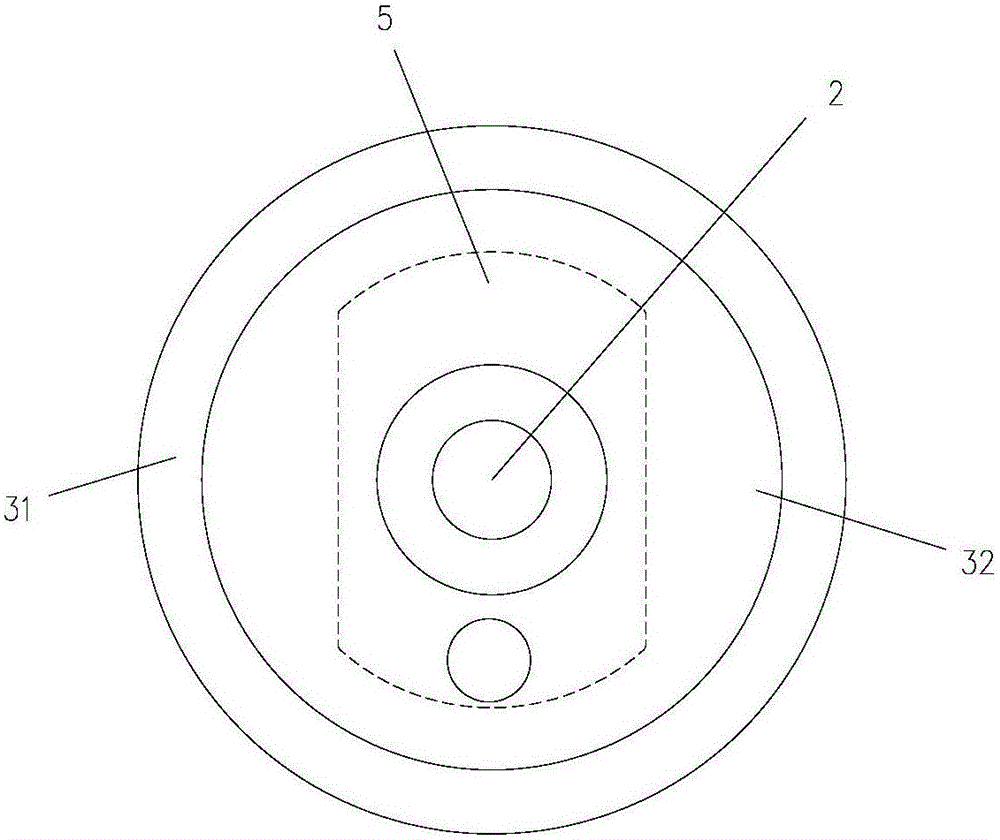

[0018] like Figure 1-3 As shown, the present invention provides a furnace wall gun swing device, including a furnace wall gun 2, a furnace wall gun support frame 4 and a swing mechanism 3, the furnace wall gun support frame 4 is fixed on the electric furnace wall 1, and the swing mechanism of this embodiment 3 includes an arc-shaped support plate 31, an arc-shaped pendulum plate 32 and a driving device 33. The arc-shaped support plate 31 is fixed on the support surface of the furnace wall gun support frame 4, and of course it can also be the support surface of the furnace wall gun support frame 4. The arc-shaped pendulum plate 32 can swing arbitrarily on the arc-shaped surface of the arc-shaped support plate 31 under the action of the driving device 33. At the same time, the furnace wall gun support frame 4 is provided with a furnace wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com