Sensor-less variable frequency constant-pressure water supply control method

A frequency conversion constant pressure, control method technology, applied in the direction of pump control, water supply devices, machines/engines, etc., can solve the problems of unable to simulate the constant pressure effect of sensors, unable to maintain remote load pressure, etc., to eliminate purchase and maintenance costs, Effects of eliminating risks and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be further described below in conjunction with the examples.

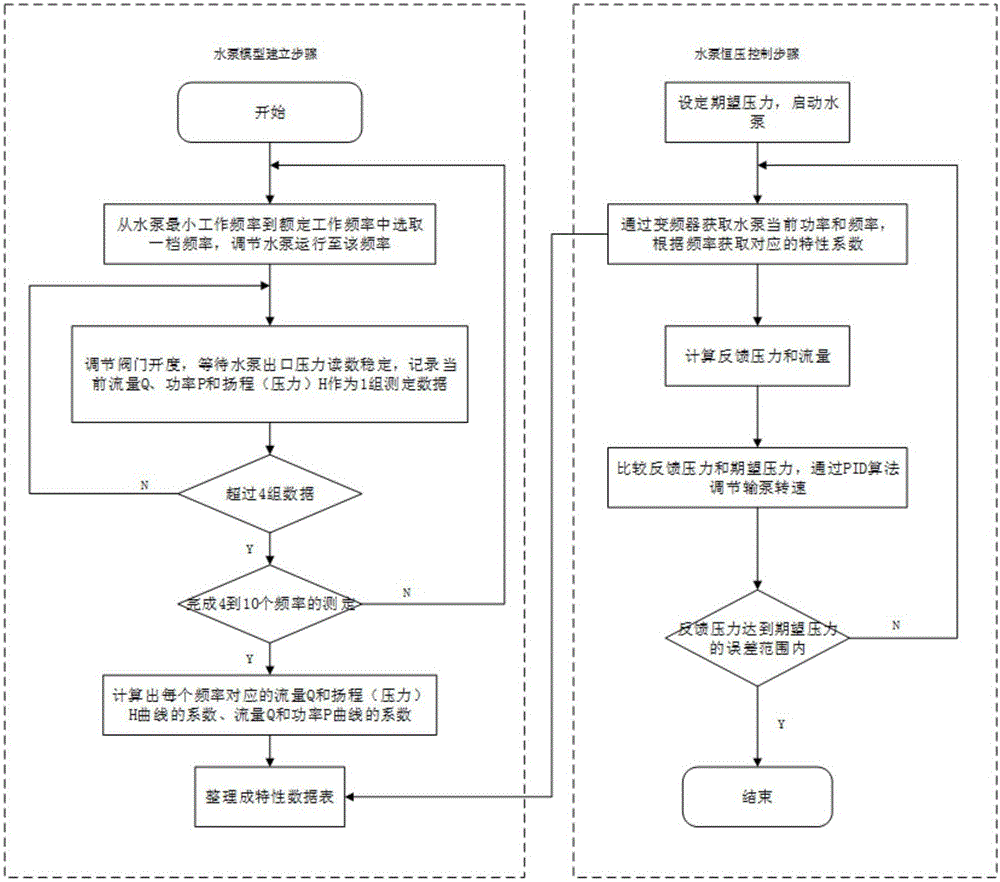

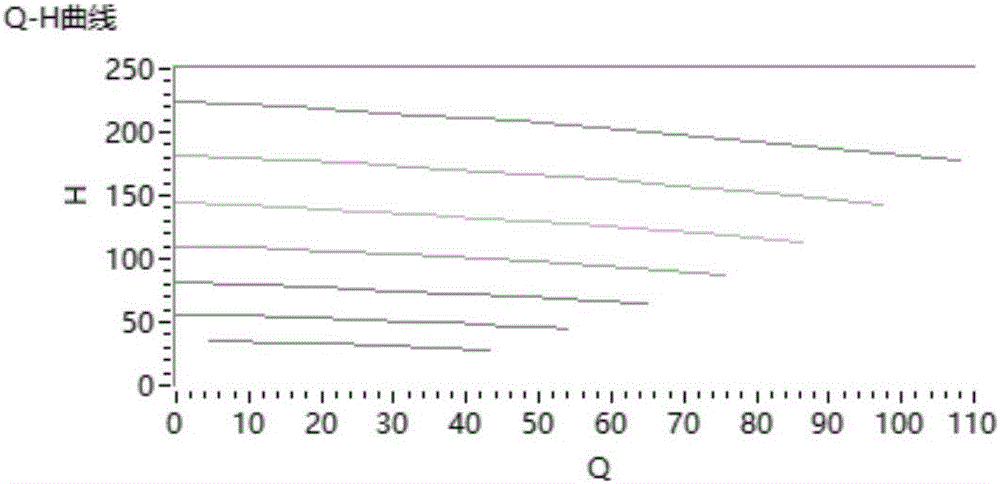

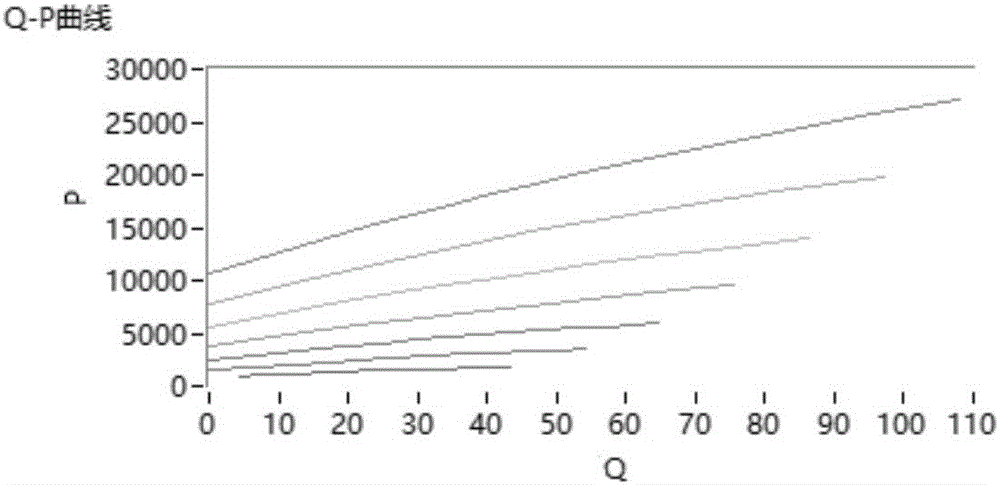

[0029] Such as figure 1 As shown, the sensorless frequency conversion constant pressure water supply control method is based on the pump characteristic model established based on the flow and head (pressure) curve, flow and power curve, and simulates the feedback of the pressure sensor through the pump characteristic model to achieve a closed-loop variable frequency constant without pressure sensor. Pressure water supply control.

[0030] Specifically, it includes a step of establishing a pump characteristic model and a step of simulating the feedback of a pressure sensor to perform closed-loop constant pressure control.

[0031] 1) Steps to establish pump characteristic model:

[0032] A) Select a frequency from the minimum working frequency of the pump to the rated working frequency, and adjust the pump to run to this frequency.

[0033] B) Adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com