Continuously variable device

A technology of stepless speed change and stepless speed changer, which is applied to belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of great application prospect and no consideration of stepless speed changer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

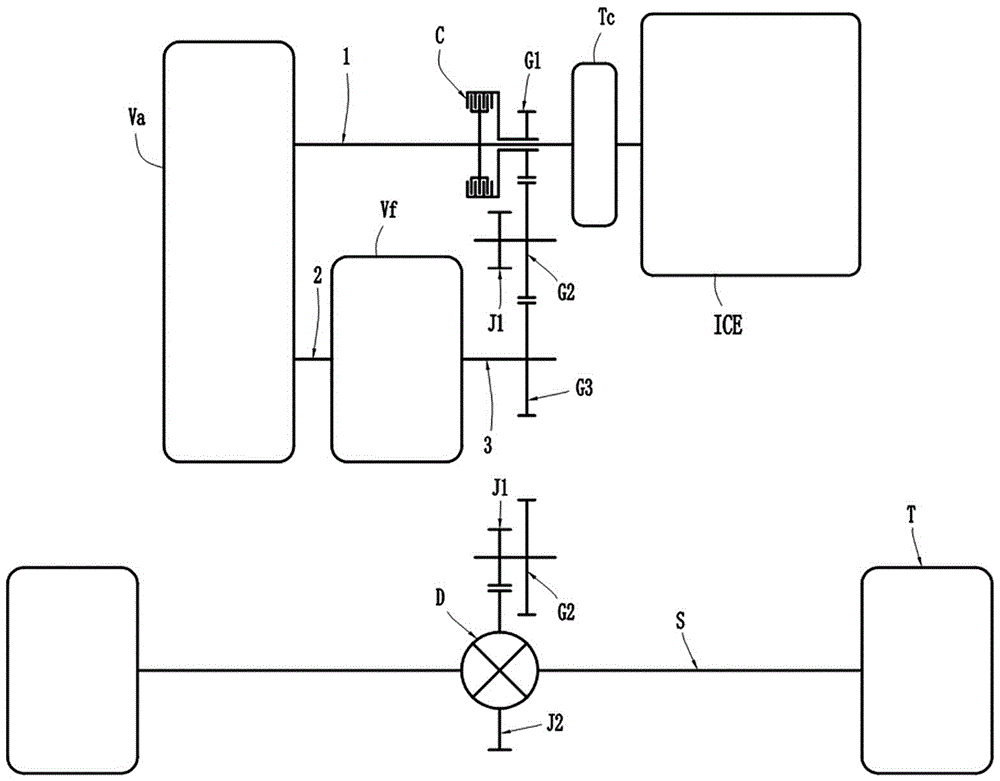

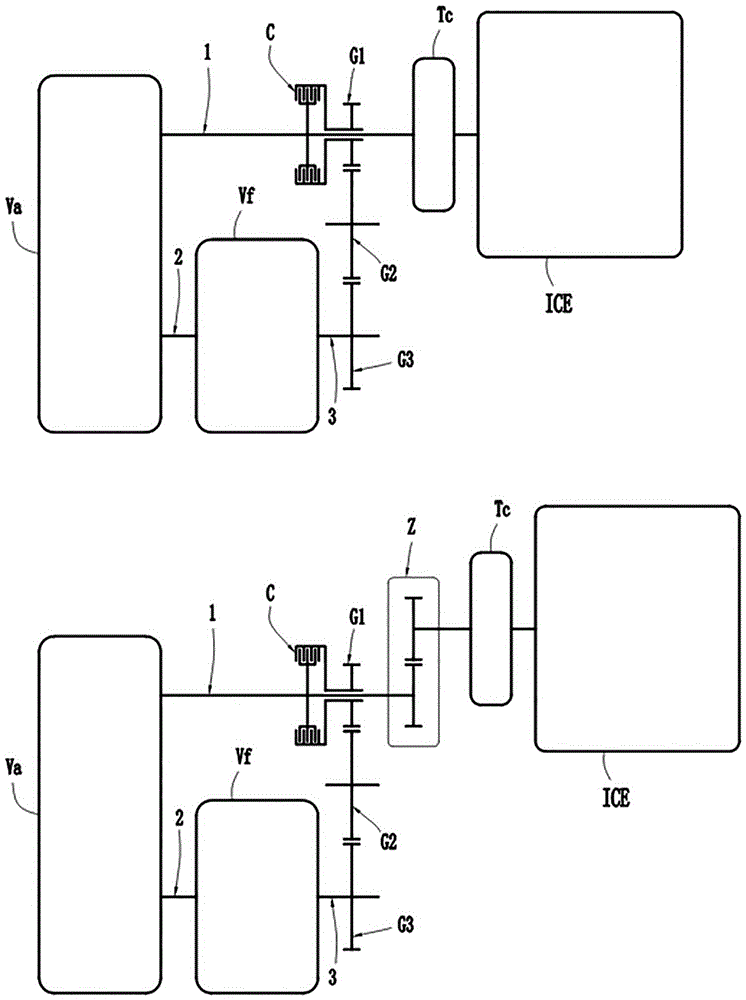

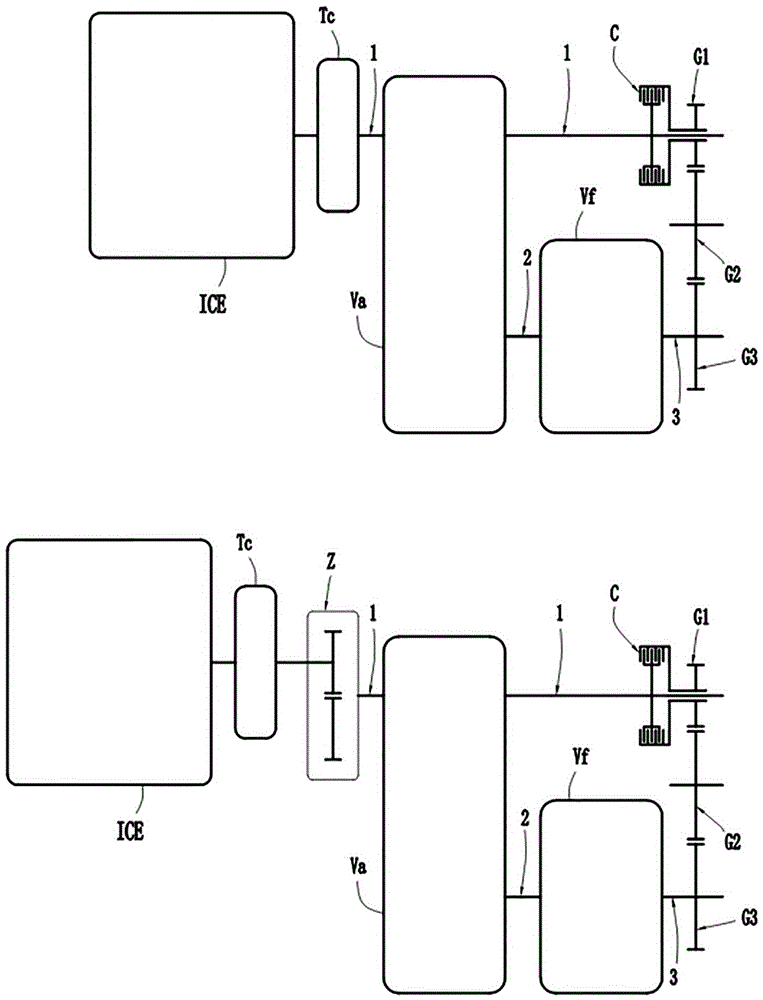

[0023] specific implementation plan

[0024]Most of the currently mass-produced continuously variable transmissions are based on a continuously variable transmission device in which the driving and driven shafts are arranged in parallel and rotate in the same direction to realize the continuously variable transmission function. For this reason, this specification firstly elaborates on the above continuously variable transmission device Va. Currently, the mass-produced mainstream continuously variable transmission Va has a range of speed ratios above 5, mostly around 6; moreover, the distance between the main and driven shafts of the continuously variable transmission Va is mostly above 100 mm. The present invention follows the method of connecting the auxiliary transmission Vf in series behind the continuously variable transmission Va, so the variable range of the speed ratio of the continuously variable transmission Va in the present invention is relatively small, about 3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com