Detonating cord de-cladding machine

A cladding and detonating cord technology, applied in the manufacture of fuses, offensive equipment, ammunition, etc., can solve the problems of low work efficiency, large workload, affecting the smooth realization of the process, and achieve low production costs, improve consistency, Guaranteed effect of peeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

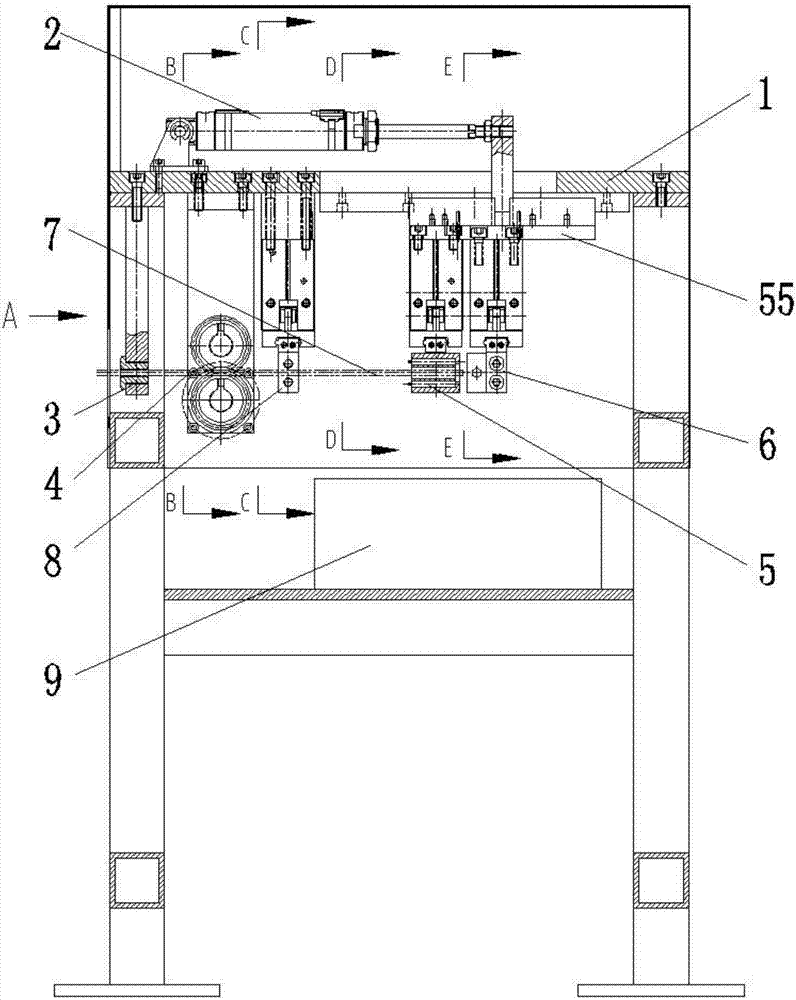

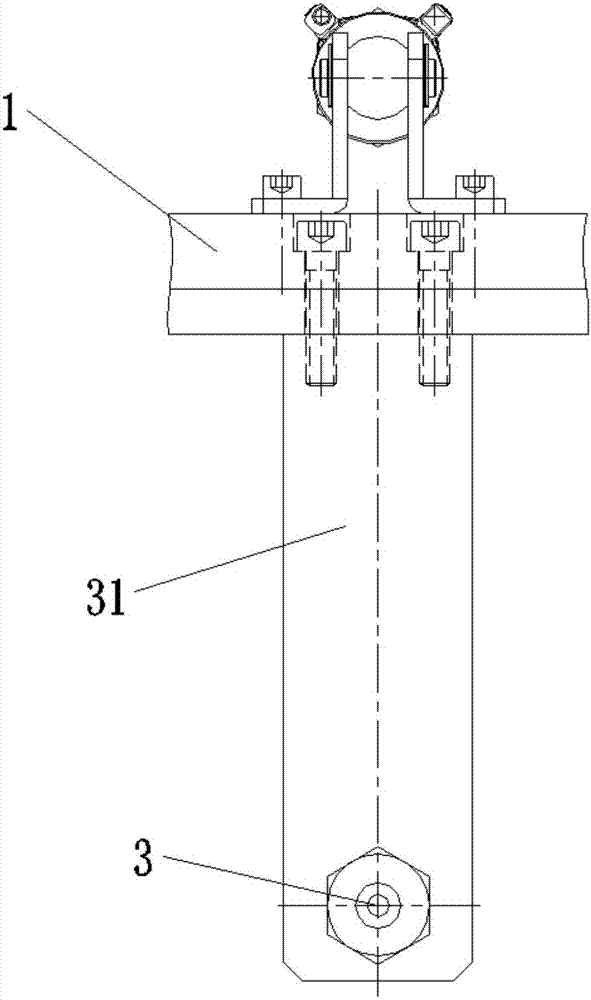

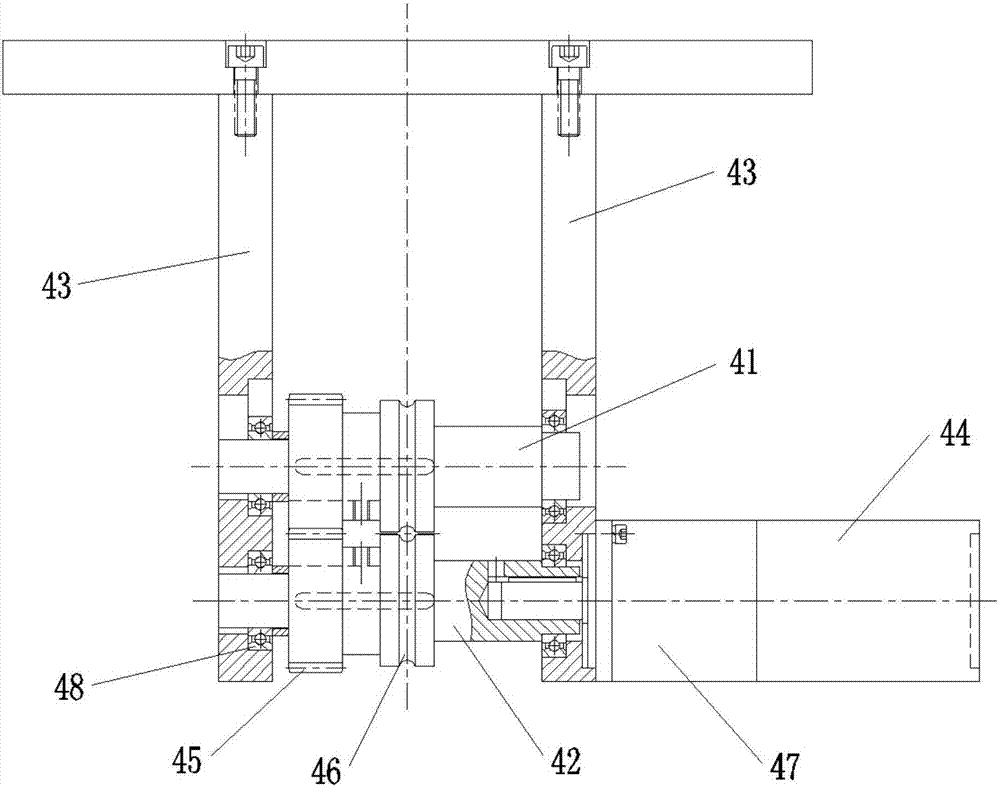

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] As shown in the figure, the detonating cord de-coating machine in this embodiment includes a mounting frame 1, a driving source 2 and a corresponding guide wire 3, a feeding mechanism 4, a hot-melt mechanism 5 and a de-coating mechanism 6. The guide wire 3 and the feeding mechanism 4 are arranged on the mounting frame 1, the hot-melt mechanism 5 and the cladding layer removal mechanism 6 are movably connected to the mounting frame 1, and the driving source 2 and the hot-melt Mechanism 5 and de-cladding layer mechanism 6 are connected.

[0024] Specifically, manually pull the detonating cord 7 through the guide wire 3 and then enter the feeding mechanism 4, and deliver it to the designated position through the feeding mechanism, and then heat the cladding layer on the detonating cord 7 by the hot-melt mechanism 5 until it softens , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com