Test method for testing service life of hydro-pneumatic spring

A technology of oil and gas springs and test methods, which is applied in the testing of mechanical components, testing of machine/structural components, vibration testing, etc., and can solve the problem of not being able to ensure that the oil and gas springs of the chassis suspension system of special vehicles meet a specific life limit and the life of oil and gas springs. Or assessment and other issues, to achieve the effect of convenient implementation, ensuring accuracy and objectivity, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

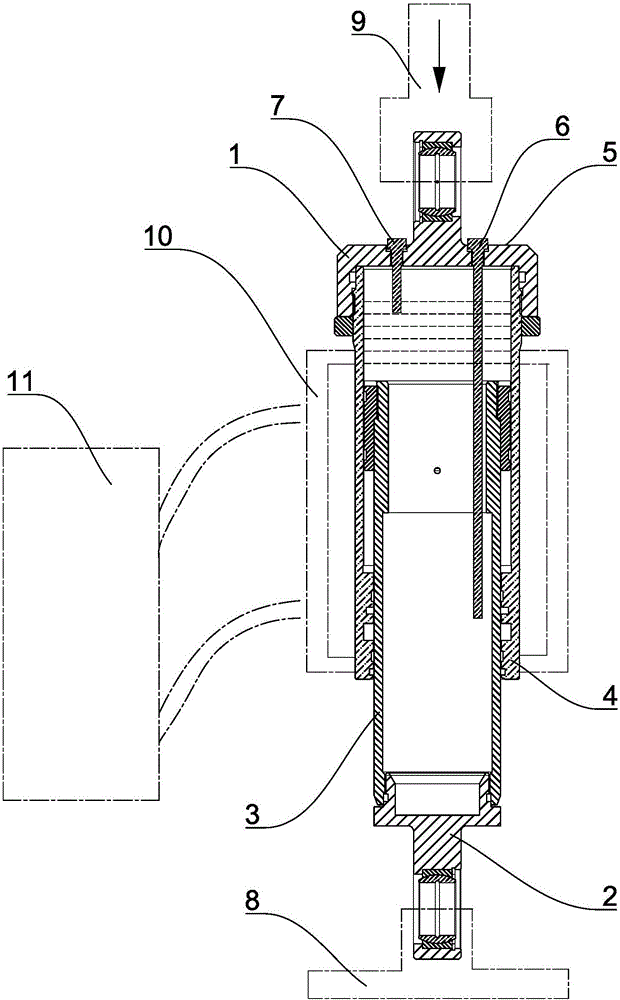

[0036]First of all, it needs to be explained that the present invention is carried out using an oil-gas spring test bench, which is equipped with an oil-gas spring loading system and a test data acquisition system for completing the loading of the tested oil-gas spring and the collection of test data. The maximum excitation stroke, maximum excitation speed, maximum excitation force, frequency range, displacement test accuracy and force test accuracy of the test bench all meet the test requirements. The oil and gas springs and products in the application documents should be understood with the same concept, and the expressions here are just for the convenience of description.

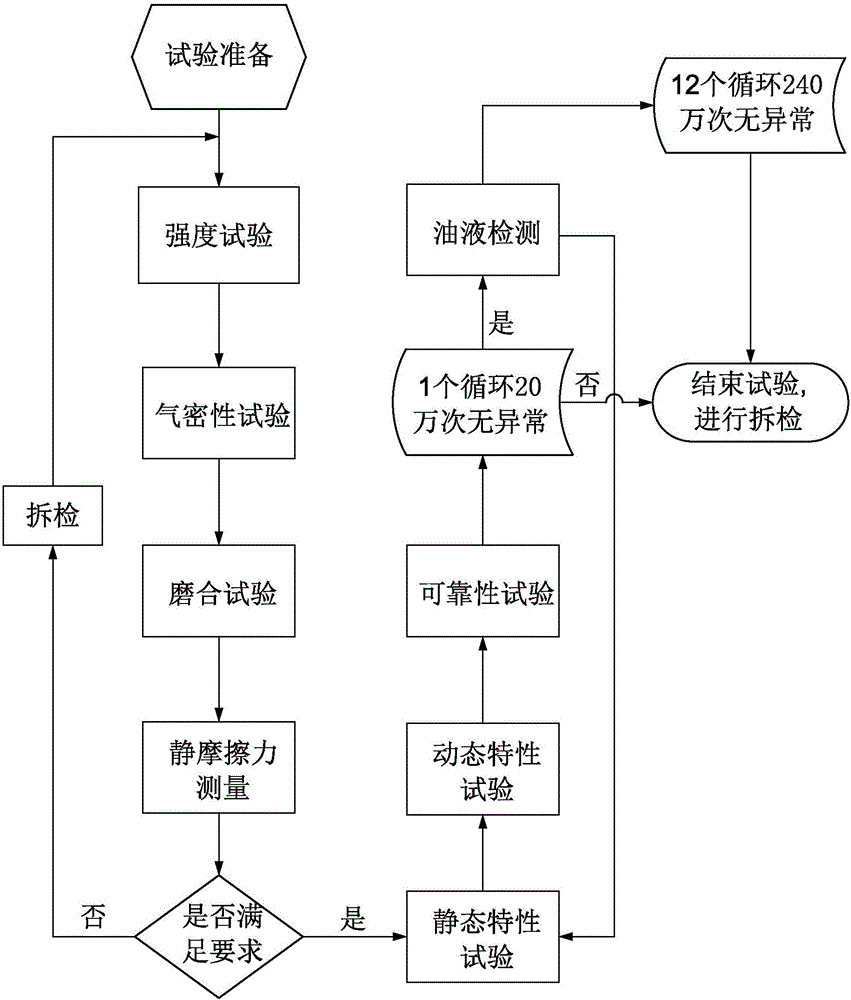

[0037] Such as figure 1 The schematic diagram of the test method of a kind of oil-gas spring life of the present invention shown, and figure 2 The flow chart of the test method for the life of the oil-gas spring shown, including the following steps:

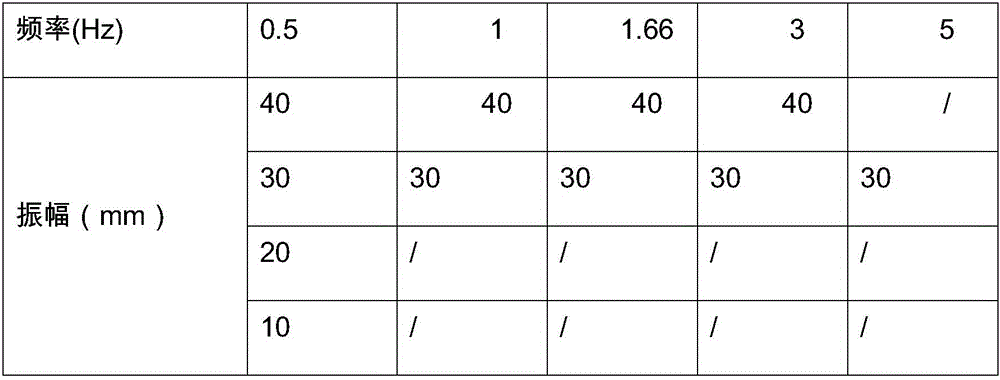

[0038] 1. The steps of static characteristic test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com