Air particle sampling automatic membrane changing device and sampler equipped with the device

An air particulate matter and automatic membrane replacement technology, which is applied in sampling devices, measuring devices, sampling and other directions, can solve the problems of difficulty in automatic sampling, many intermediate transmission steps, and high positioning accuracy, so as to meet the needs of long-term sampling and reduce labor intensity. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

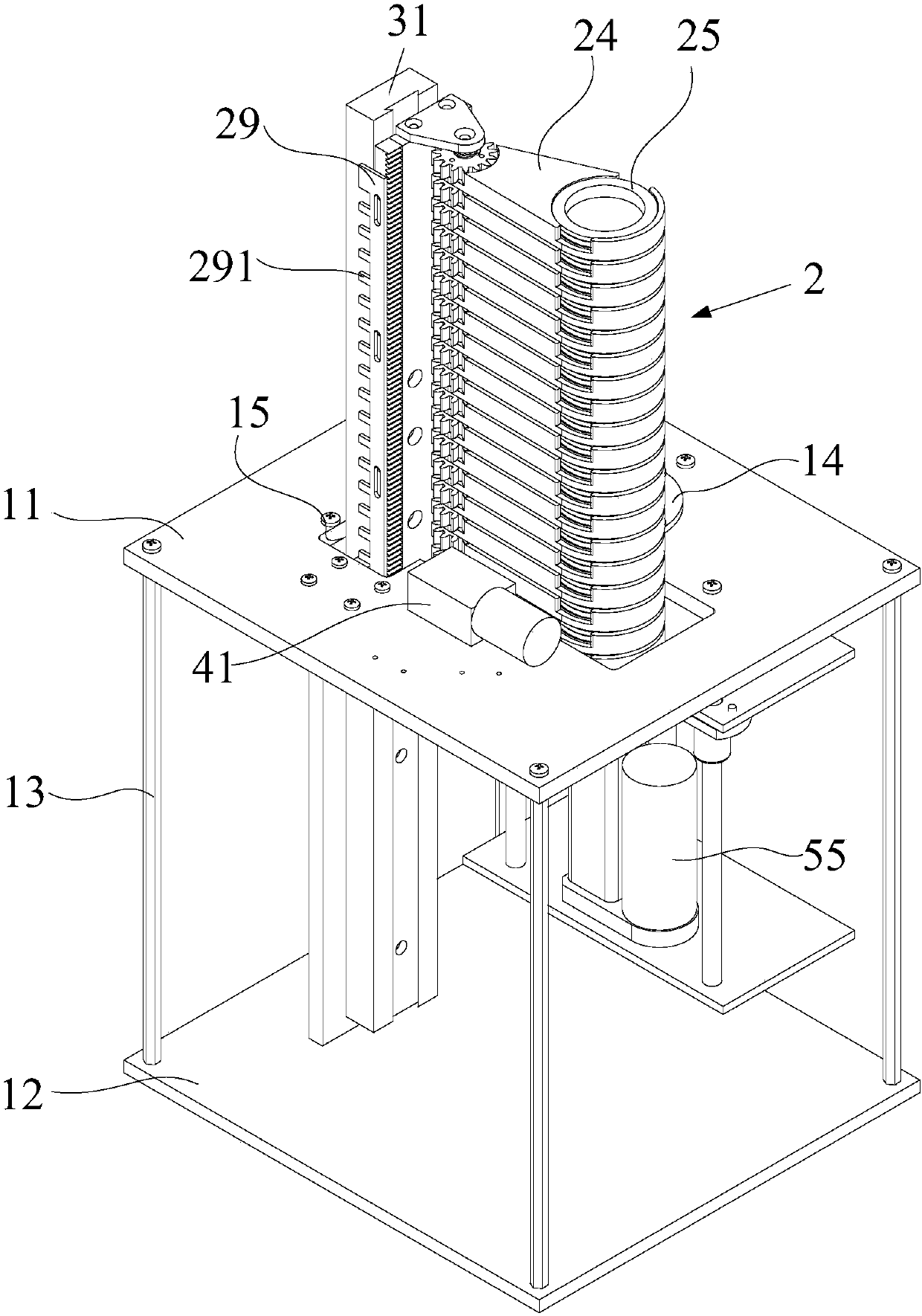

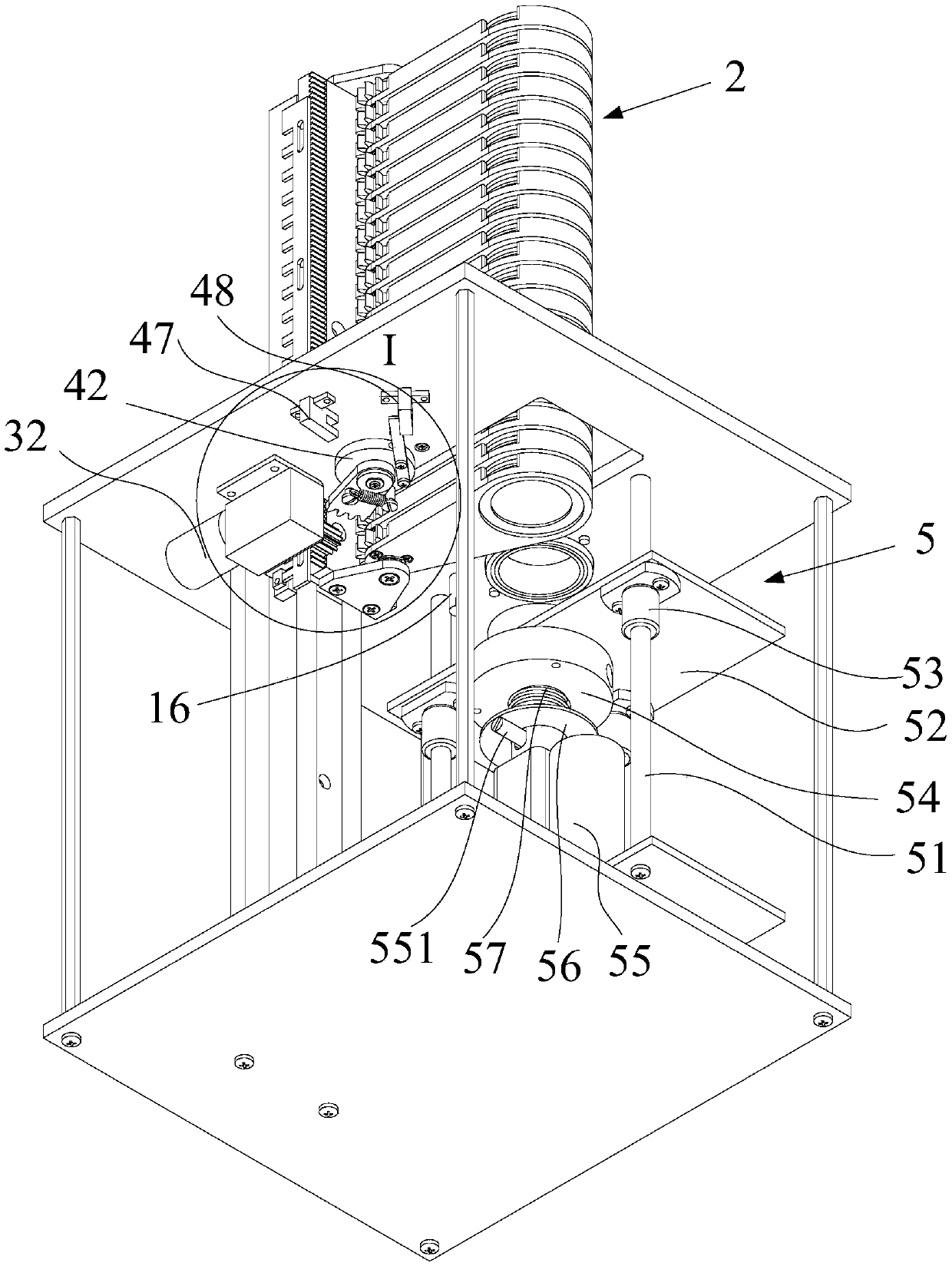

[0027] Example: such as figure 1 , figure 2 As shown, an automatic membrane changing device for air particulate matter sampling includes a frame 1, a filter membrane holder 2, a filter membrane holder lifting mechanism 3, a filter membrane holder rotation mechanism 4 and a membrane pushing mechanism 5. The motor and the photoelectric switch of the whole device are electrically connected with the sampler controller.

[0028] The frame 1 includes a top plate 11 and a bottom plate 12, and a fixed column 1 is connected between the top plate 11 and the bottom plate 12. The top plate 11 is provided with an air inlet 14 and a filter membrane clamping through hole 15, and a filter membrane clamping through hole 15 A linear guide rail 31 for installing the membrane cartridge 2 is installed vertically inside.

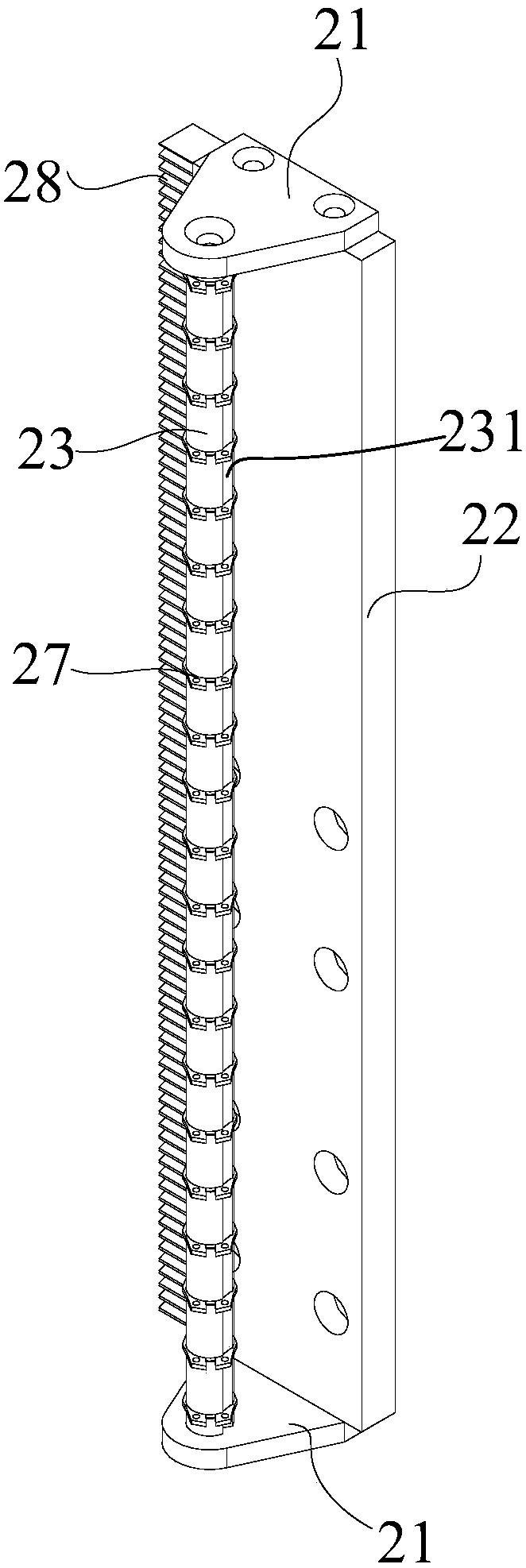

[0029] see image 3 , Figure 4 , the filter membrane holder 2 includes a filter membrane holder side plate 22 and a central axis 23 arranged vertically, the tops of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com