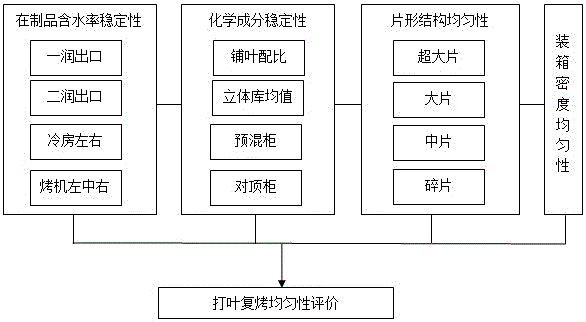

Evaluation method for threshing and redrying uniformity

A technology for threshing, redrying and evaluating methods, which is applied in measuring devices, instruments, scientific instruments, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

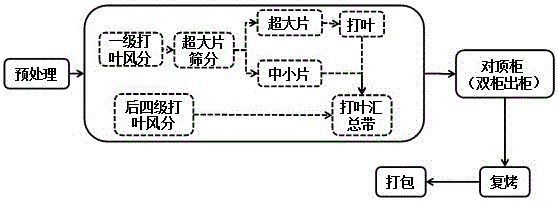

Method used

Image

Examples

Embodiment 1

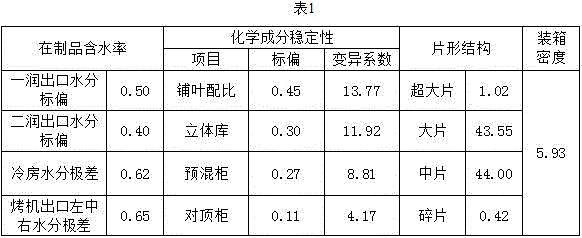

[0025] It is processed with grade formula tobacco leaves (or modules) of a certain China Tobacco Company, and its uniformity evaluation is shown in Table 1:

[0026]

[0027] It can be seen from Table 1 that in the grade processing process of the above-mentioned grade formula tobacco leaves, among the first-level evaluation indicators, the moisture standard deviations of the first and second moisturizer outlets are 0.50 and 0.40 respectively, the moisture range of the cold room is 0.62, and the moisture range of the left, middle and right outlets of the roasting machine is very poor. 0.65, the control process of the moisture content of the finished product is stable; among the secondary evaluation indicators, the nicotine standard of the tobacco leaf sample after the tobacco leaf sample mixed with the tobacco leaf sample in the pre-mixing cabinet and the top cabinet The deviations were 0.45, 0.30, 0.27 and 0.11, respectively, and the coefficients of variation of nicotine wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com