Rotary test mechanism and PCB test method based on rotary test mechanism

A testing mechanism and technology to be tested, which is applied in electronic circuit testing, printed circuit testing, measuring device casing, etc., can solve the problems of low accuracy of test results, qualified products and unqualified products, low test efficiency, etc., and achieve accurate test results High reliability, space saving, and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] Preferred embodiment:

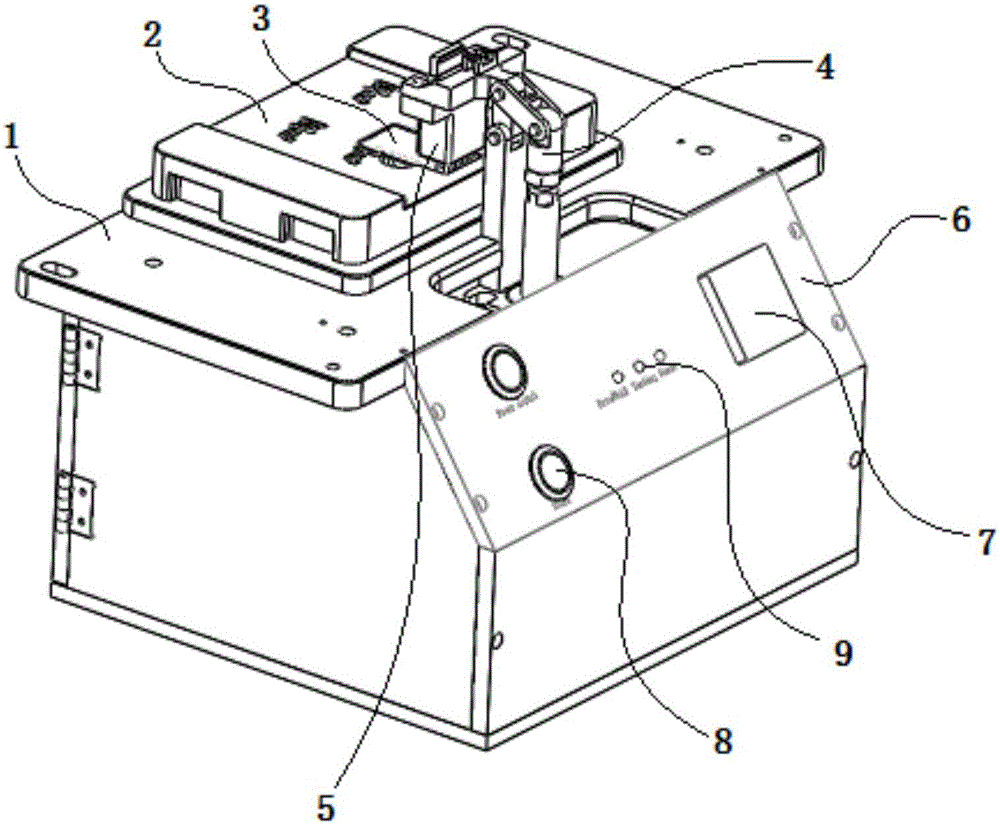

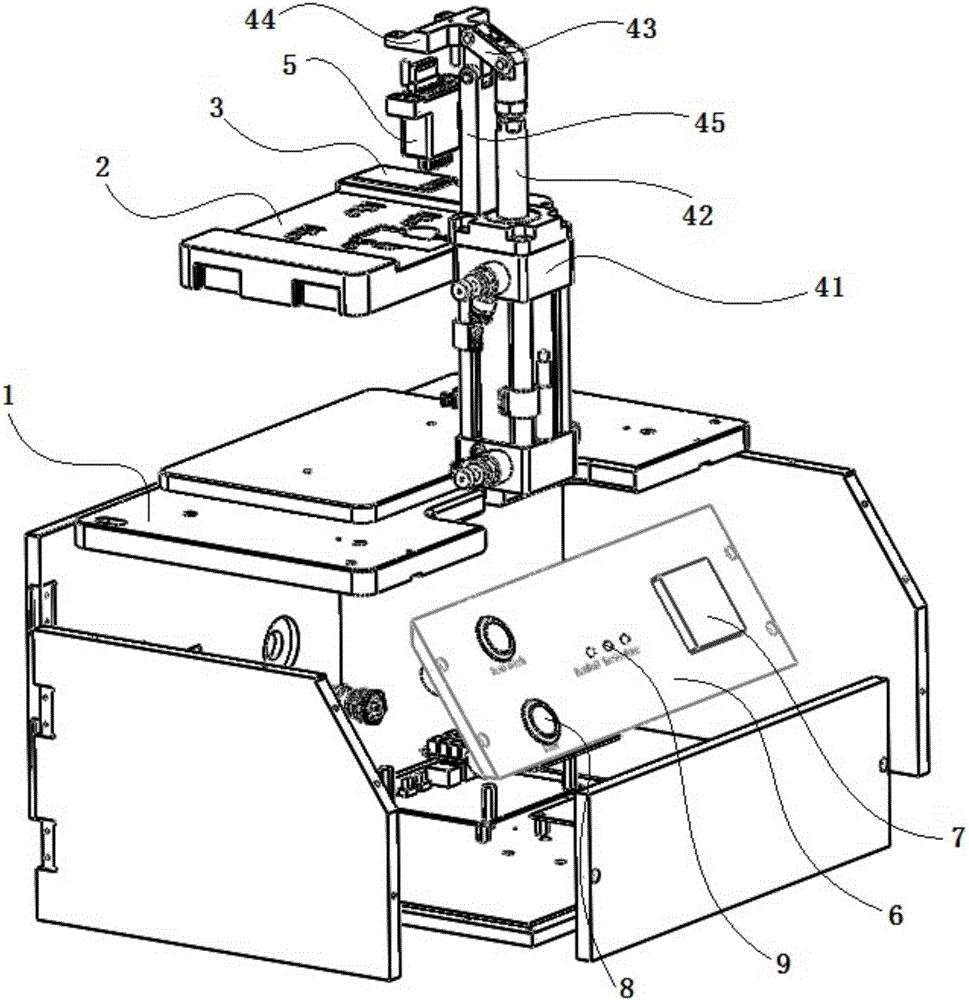

[0025] The preferred embodiment discloses a rotary testing mechanism. Such as figure 1 with figure 2 As shown, the rotary test mechanism includes a test platform 1, on which a carrier 2 for placing the product to be tested 3 is detachably arranged, and a rotary pressing mechanism 4 and a test probe 5 are arranged above the carrier 2, Rotating the pressing mechanism 4 can drive the test probe 5 to lean against the object to be tested 3 .

[0026] Place the product 3 to be tested in the carrier 2, and rotate the pressing mechanism 4 to drive the test probe 5 to press down until the test probe 5 abuts against the product 3 to be tested, and then the test can be started; The signal is exported and the test is completed; the rotating pressing mechanism 4 drives the test...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap