Large power loaded MOS pipe heat radiation apparatus

A high-power load, MOS tube technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of large heat generation, low effective utilization of radiators, large wind resistance, etc., to achieve comprehensive personal safety protection, radiator The effect of high utilization rate and high working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

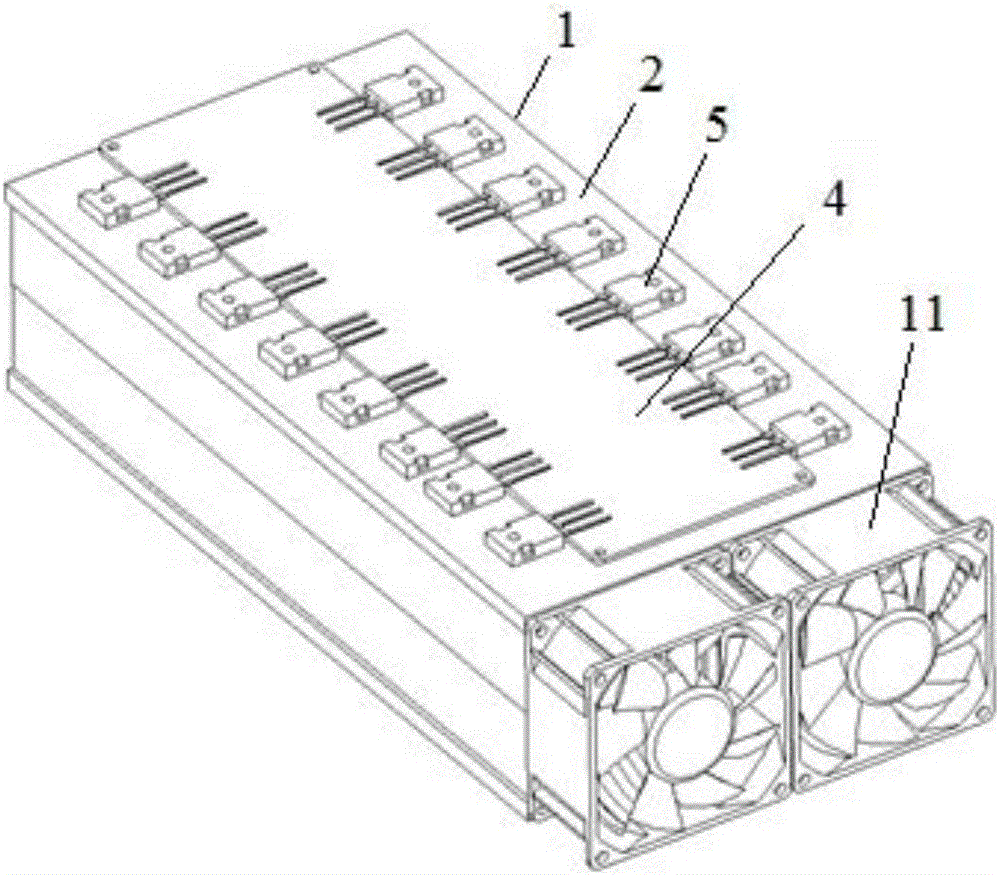

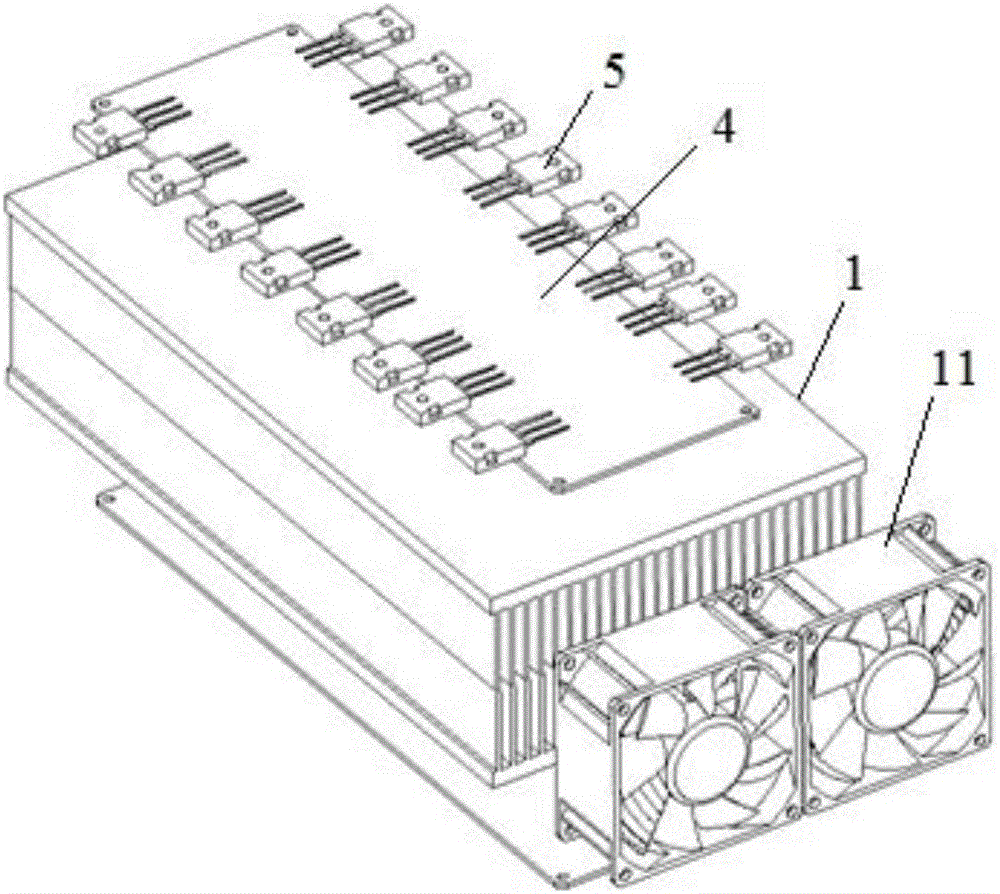

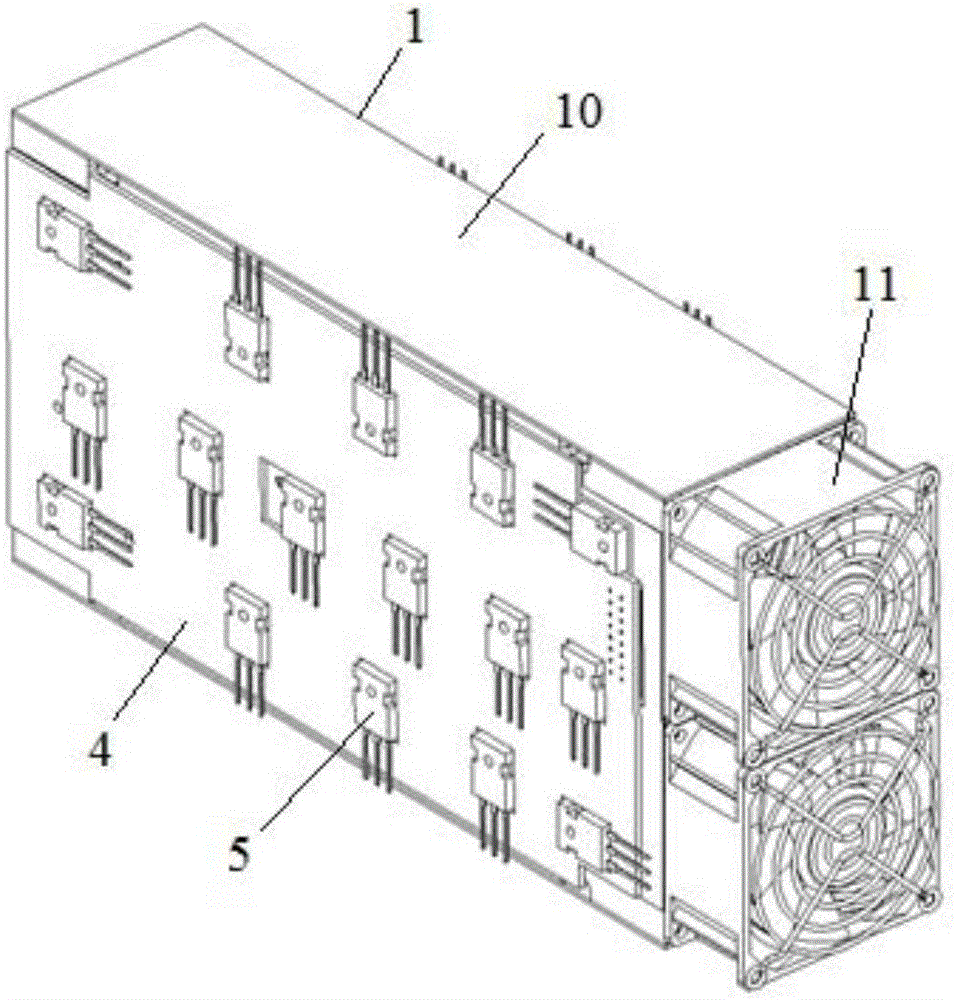

[0024] Such as image 3 , Figure 4 As shown, the high-power load MOS tube cooling device in this embodiment includes a radiator 1, a fan 11 is installed at the inlet end of the radiator 1, and a circuit board 4 is respectively fixed on the substrate 2 on both sides of the radiator 1. A plurality of MOS tubes 5 are installed on the circuit board 4, the body 5.1 of the MOS tube 5 is close to the surface of the substrate 2, and a fireproof insulation board 7 is arranged between the circuit board 4 and the surface of the substrate 2 of the radiator 1, and the radiator 1 An anti-vibration pad 12 is arranged between the fan 11.

[0025] In this embodiment, circuit boards 4 are arranged on both sides of the radiator 1, and MOS tubes 5 are installed on each circuit board 4, so that more MOS tubes can be installed without increasing the size of the radiator, and the utilization rate of the radiator is improved. high.

[0026] The fireproof insulating board 7 of the present embodime...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap