Equipment clamp punching positioning device

A technology for equipment wire clips and hole positioning, which is applied in the manufacturing of contacts, etc., can solve the problems of inaccurate punching, trouble in determining the position of the drip hole punching, discharge, etc., to improve work efficiency, simple and reliable measurement, and ensure normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

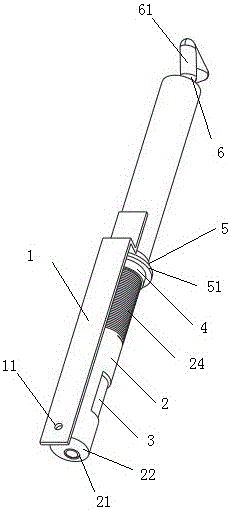

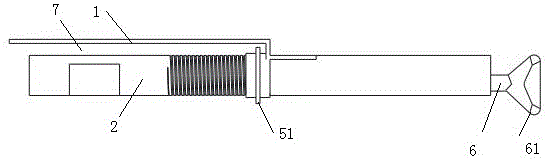

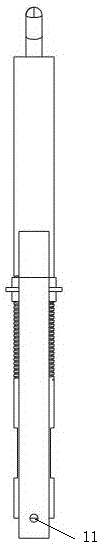

[0019] The device wire clip punching and positioning device of the present invention includes a main body rod 2, the main body rod 2 is cylindrical, the positioning ruler 1 is fixed on the main body rod 2, and the positioning ruler 1 can be fixed on the main body rod by rivets or screws. It can also be fixed by other means such as welding. There is a gap 7 between the positioning ruler 1 and the main body rod, the positioning ruler 1 front end is provided with a positioning hole 11, the lower edge of the positioning hole 11 and the front end face 23 of the main body rod are located on the same horizontal plane, and the front portion of the main body rod is provided with a groove 23 for positioning. The wheel 3 is placed in the groove 23, and the rotating rod 6 penetrates the cavity of the main body rod from the rear end of the main body rod 2 and enters the fixed cavity 31 on the positioning wheel 3, and the positioning wheel 3 is fixed in the groove 23, and the positioning whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com