Dental implant

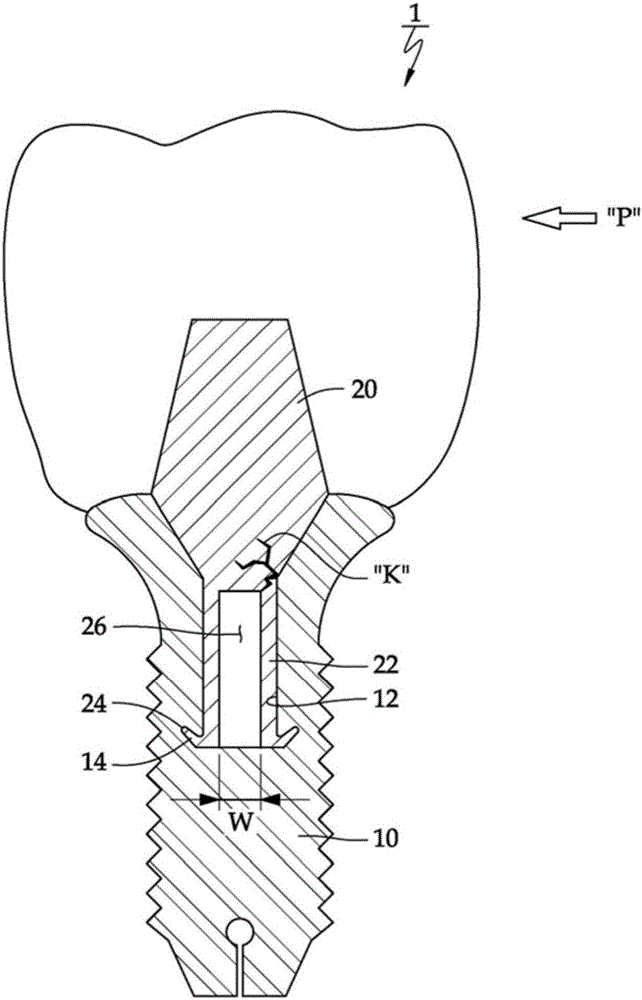

A technology for oral implants and implants, which is applied in dental implants, medical science, dentistry, etc., can solve problems such as breakage, inability to properly ensure the thickness of elastic fastening pillars 22, and inability to design allowable bending space, etc., to ensure the structure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

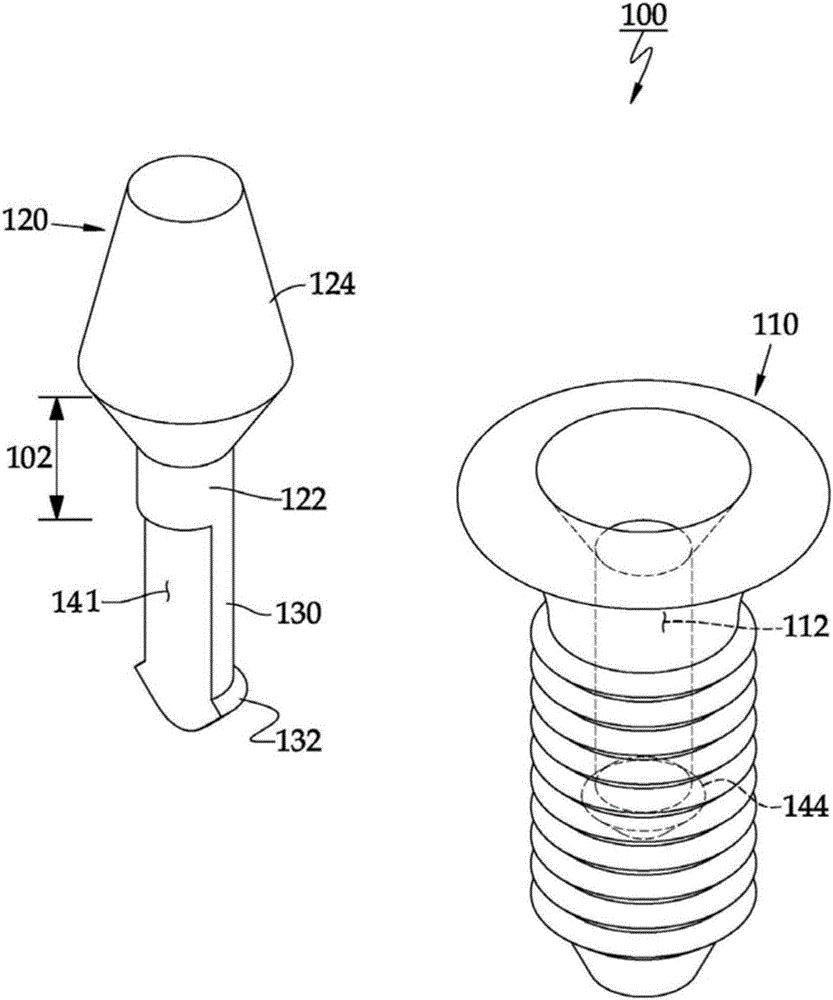

[0038] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] Such as figure 2 As shown, the oral implant 100 according to the present invention includes: an implant 110 with a shaft hole 112 formed on the top and a guide groove formed inside to be implanted into the alveolar bone; and an abutment 120 inserted into the shaft hole 112 of the implant 110 In addition, it is elastically combined with the lower fastening shaft 122 of the above-mentioned implant 110 and the upper installation part 124 of the installation prosthesis (not shown). The basic structure as previously described is then the same as the existing structure.

[0040] However, different from the existing structure, the structure of the present invention is as follows. The above-mentioned abutment 120 only forms an elastic fastening strut 130 on the lower fastening shaft 122, and the elastic fastening strut 130 has a shaft hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com