Laminating apparatus

A lamination device, lamination roller technology, applied in the lamination device, lamination, rolling mill control device, etc., can solve the problems of incorrect assembly of products, insufficient lamination pressure, loss of performance, etc., to achieve excellent reliability, structure The effect of economy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

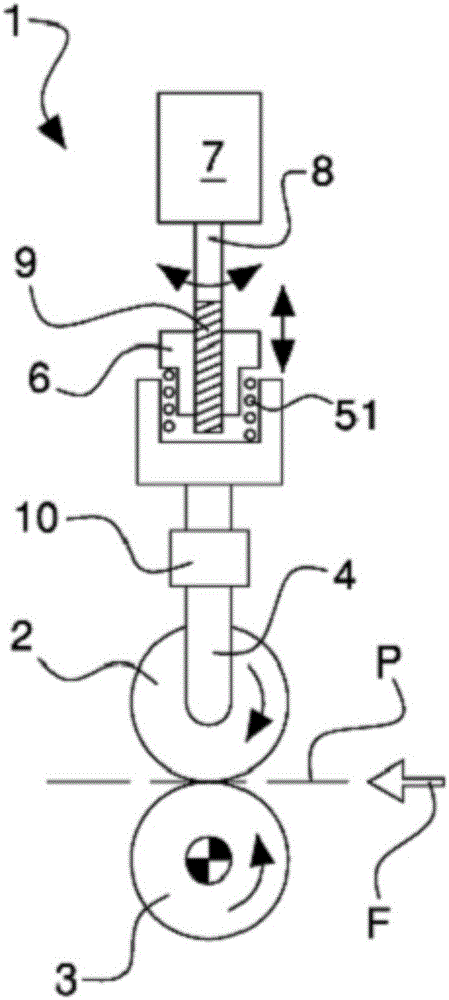

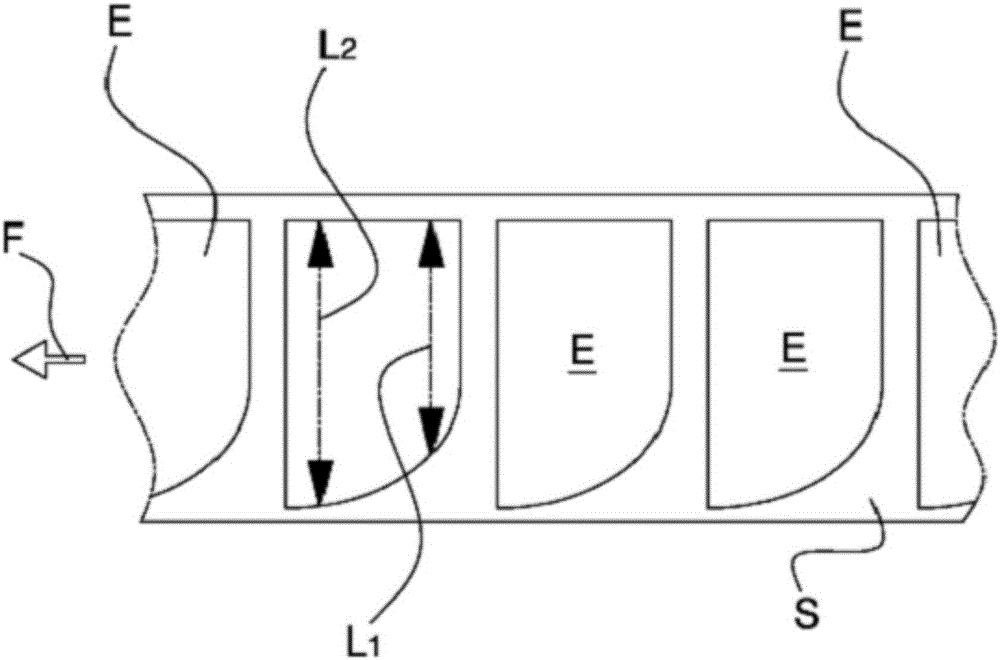

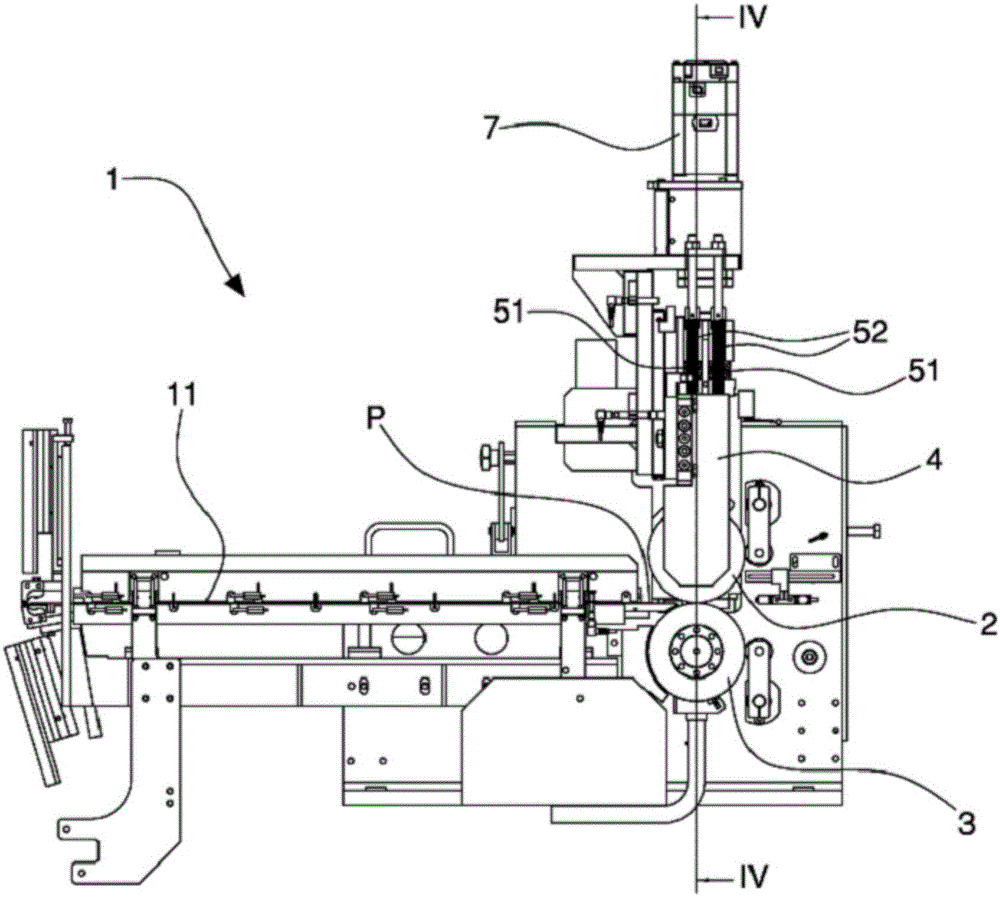

[0021] refer to the above Figure 1 to Figure 6 , numeral 1 denotes the whole of a lamination device which can be used in particular for the manufacture of electric energy accumulating devices (batteries, capacitors, etc.). In particular, the lamination device 1 can be used to couple at least one flat electrode E of non-rectangular shape with at least one separation membrane S. For greater clarity of illustration, the same reference numerals are used in the drawings to designate similar parts of several example embodiments.

[0022] Apparatus 1 comprises a first (upper) lamination roll 2 and a second (lower) lamination roll 3 coupled together and facing each other to define The lamination zone that extends between the rolls. In particular, the two lamination rollers 2 and 3 have axes of rotation parallel (horizontal) to each other. The lamination zone may extend widthwise in a direction parallel to the axes of the two lamination rolls 2 and 3 .

[0023] The object to be la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com