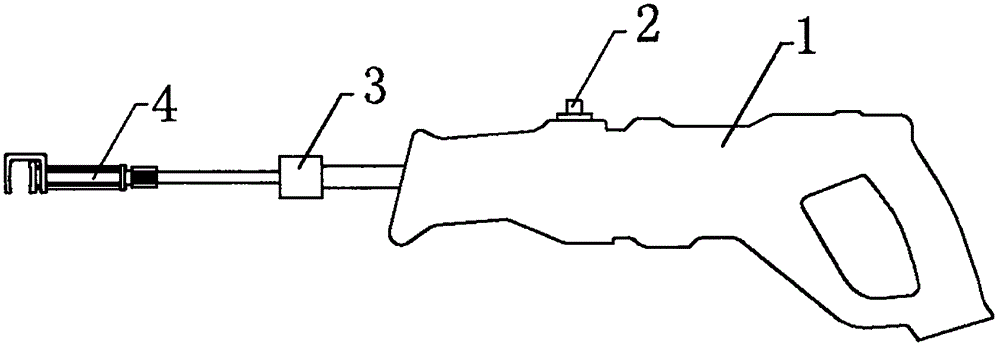

Reciprocating saw-based small fruit vibrating picking machine with adjustable clamping aperture

A technology of reciprocating saws and picking machines, which is applied to picking machines, harvesters, agricultural machinery and implements, etc. It can solve problems such as the inability to harvest branches and the inability to continuously adjust the caliber of the vibrating head, and achieve the effect of a simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

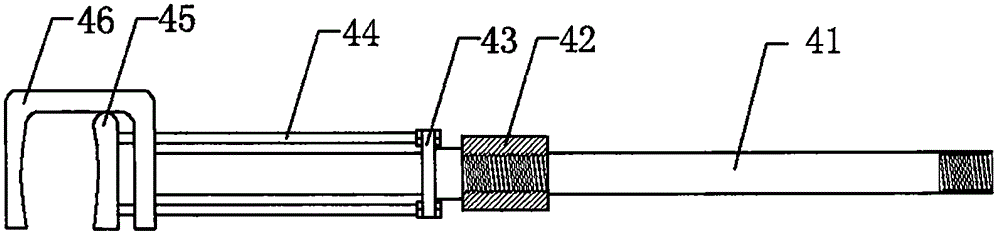

[0013] The power of the reciprocating saw (1) is transmitted to the vibrating rod (4) through the vibrating rod connecting sleeve (2), and the vibrating rod (4) transmits the power to the U-shaped clamping port (46) through the connecting rod (41) The branches clamped by the type clamping mouth (46) vibrate under the effect of exciting force. The clamping block (45) and the sliding sleeve (43) are connected by a push rod (44). Double nuts are used for clamping and fixing. When the sliding sleeve (43) slides to the left on the vibrating rod (41), the clamping block (45) also slides to the left, and the clamped branch is clamped in the U-shaped clamping opening. Clamp, then rotate the fixing nut (42) to fix the right end of the sliding sleeve (43) in order to prevent sliding. After the vibration is over, unscrew the fixing nut (42), and the U-shaped clamping mouth (46) can be taken off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com