Using method of sticky traps

An insect sticky board and adhesive technology, which are applied in botanical equipment and methods, devices and applications for catching or killing insects, etc., can solve problems such as poor trapping effect, and achieve the effect of avoiding trapping and killing and adult trapping and killing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

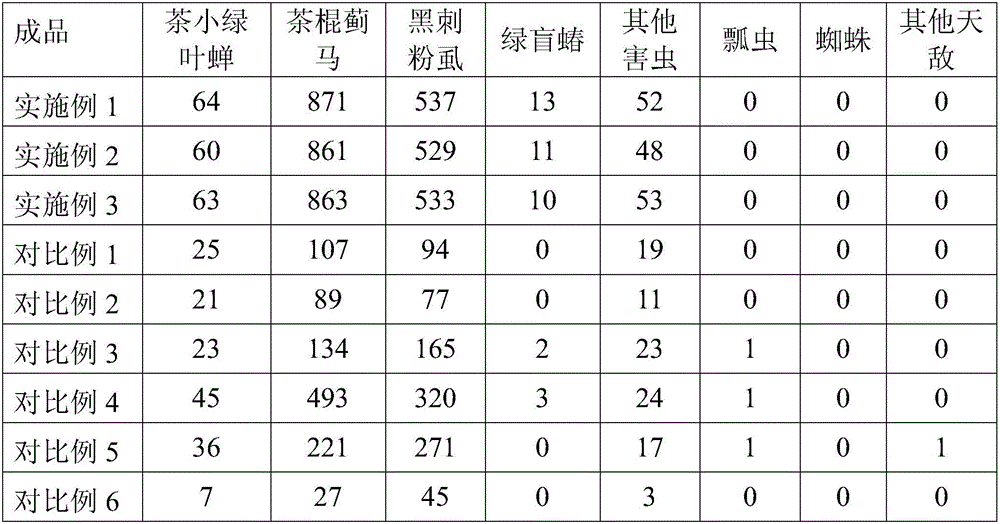

Examples

Embodiment 1

[0019] A method for preparing a sticky insect board includes the following steps: smear a yellow-green color with a wavelength of 560 to 580 nm on a carrier board with a thickness of 0.3 mm, and then apply an adhesive, the thickness of the adhesive is 0.23 to 0.24 mm, and then Air-dried for 3 hours at a temperature of 24°C and a humidity of 62%, sliced, covered, and punched. Among them, the carrier plate is made by pressing a mixture of straw cellulose and resin; the adhesive is made by mixing polybutene and C9 petroleum resin, and the mass ratio of polybutene and C9 petroleum resin is 3:1. The size of the slice is 17×25cm; the film is covered with 157g kraft wax paper; the number of holes is two, which are located at both ends of the slice.

Embodiment 2

[0021] A method for preparing a sticky insect board includes the following steps: smear a yellow-green color with a wavelength of 560 to 580 nm on a carrier board with a thickness of 0.3 mm, and then apply an adhesive, the thickness of the adhesive is 0.23 to 0.24 mm, and then Air-dried for 5 hours at a temperature of 25°C and a humidity of 65%, sliced, coated, and punched. Among them, the carrier plate is made of rice straw cellulose and resin mixture under pressure; the adhesive is made of polybutene and C9 petroleum resin, and the mass ratio of polybutene to C9 petroleum resin is 4:1. The size of the slice is 17×25cm; the film is covered with 157g kraft wax paper; the number of holes is two, which are located at both ends of the slice.

Embodiment 3

[0023] A method for preparing a sticky insect board includes the following steps: smear a yellow-green color with a wavelength of 560 to 580 nm on a carrier board with a thickness of 0.3 mm, and then apply an adhesive, the thickness of the adhesive is 0.23 to 0.24 mm, and then Air-dried for 1 hour at a temperature of 23.5°C and a humidity of 60%, sliced, covered, and punched. Among them, the carrier plate is made by pressing a mixture of straw cellulose and resin; the adhesive is made by mixing polybutene and C9 petroleum resin, and the mass ratio of polybutene to C9 petroleum resin is 5:1. The size of the slice is 17×25cm; the film is covered with 157g kraft wax paper; the number of holes is two, which are located at both ends of the slice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com