Wireless-control-based four-degree-of-freedom TIG automatic surfacing rotary workbench

A rotary table and automatic surfacing welding technology, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as difficult to pile up complex parts, deterioration, and influence on molding quality, and achieve stable and reliable wire feeding and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

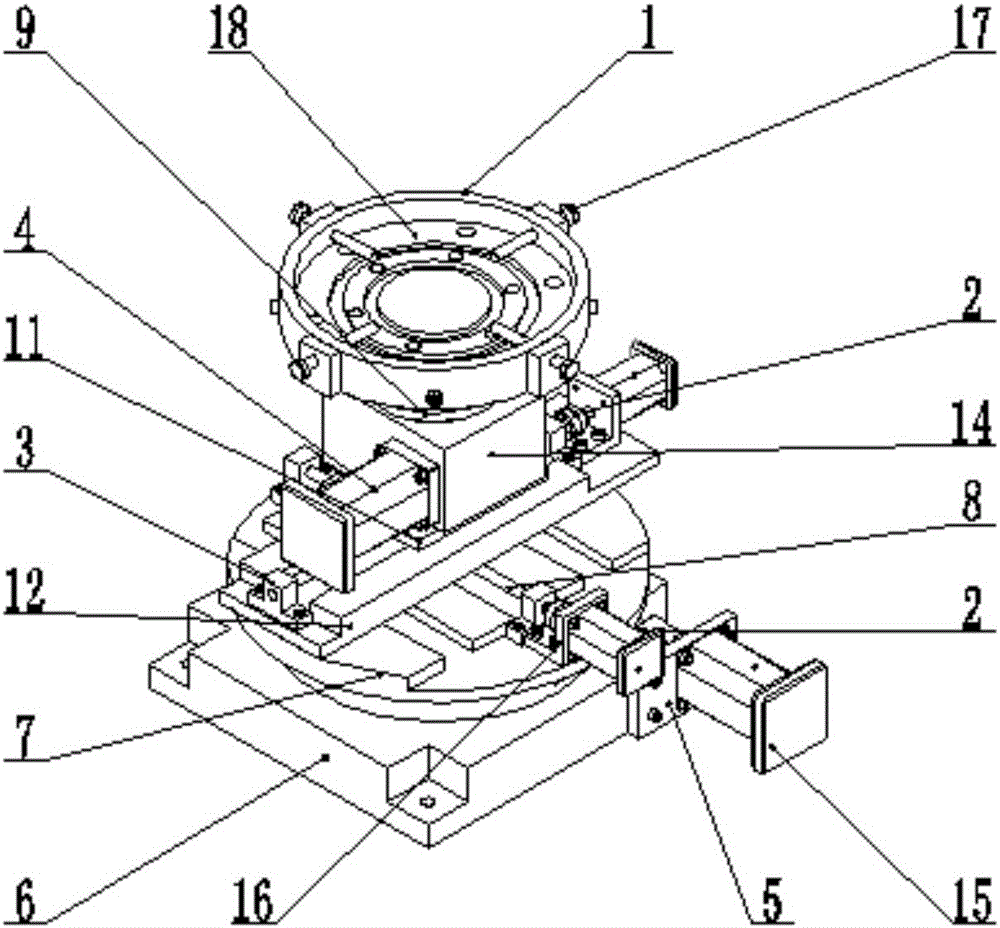

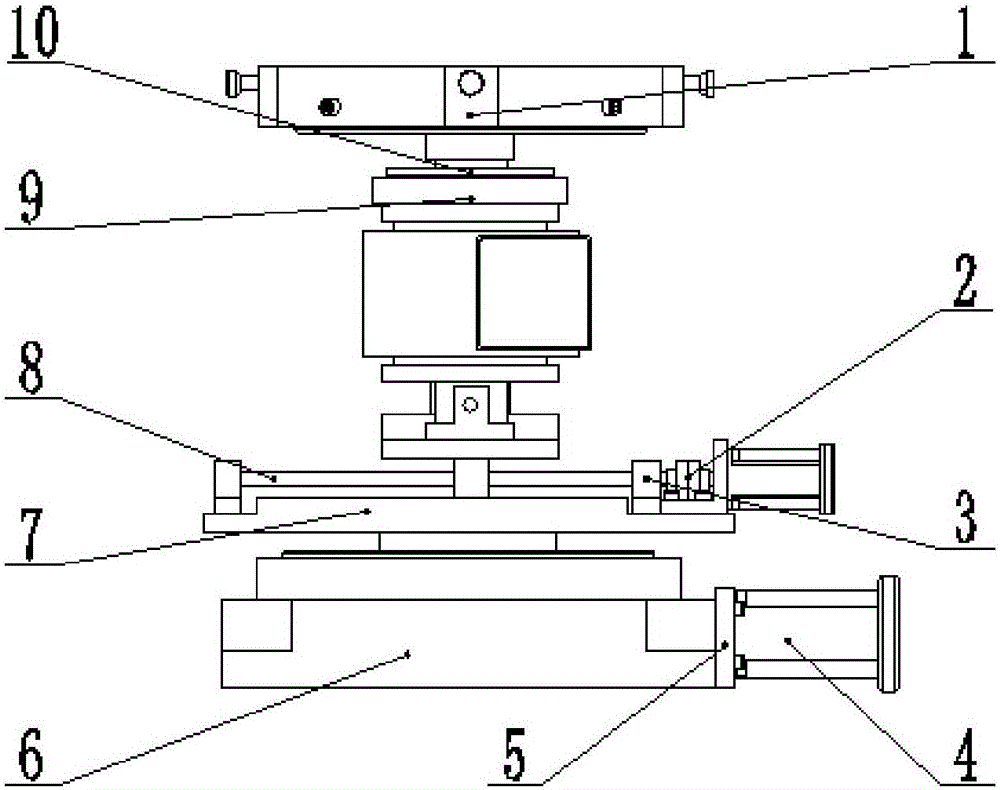

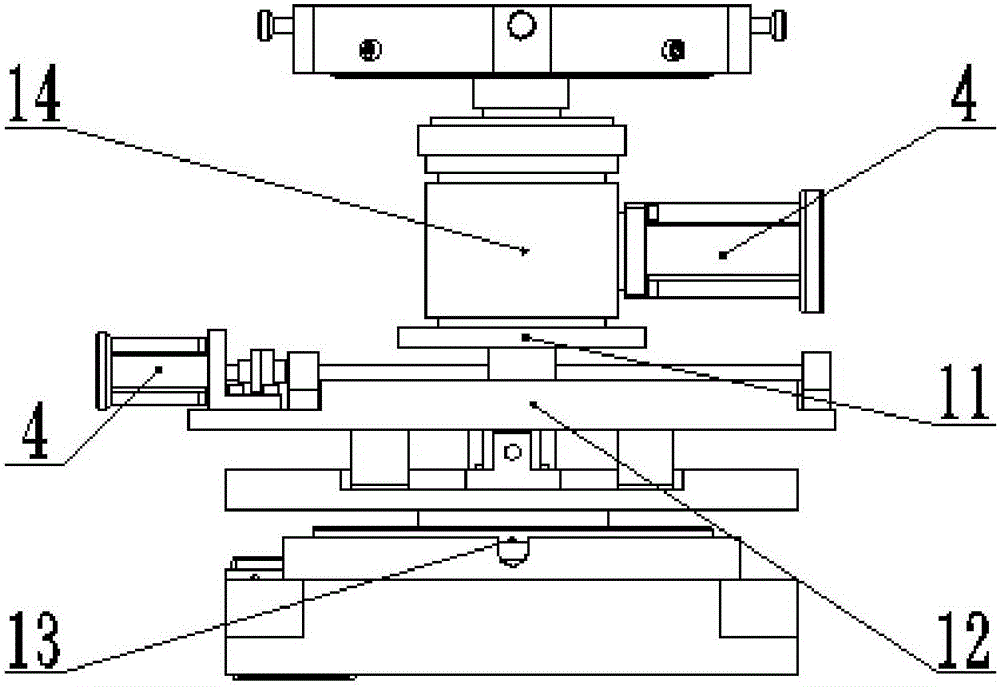

[0019] Such as Figure 1-4 As shown, a four-degree-of-freedom TIG automatic surfacing rotary workbench based on wireless control includes a Y-axis moving stage 11 and an X-axis moving stage 12. The Y-axis moving stage 11 is stacked on the upper surface of the X-axis moving stage 12. A worm gear reducer 14 is fixed on the top surface of the shaft moving table 11, a screw shaft 8 is arranged on the bottom of the Y-axis moving table 11, both ends of the screw shaft 8 are fixed on the screw shaft fixing seat 3, and the worm gear reducer The side of 14 is fixed with a servo motor 4, and the top surface of the worm gear reducer 14 is fixed with a turntable disk 18; the bottom of the X-axis moving table 12 is fixed on the base turntable disk 7, and the bottom of the X-axis moving table 12 is provided with a screw shaft 8. Both ends of the screw shaft 8 are fixed on the screw shaft fixing seat 3. The servo motors 4 on the Y-axis moving table 11 and the servo motors 4 at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com