Winder mounting device for strength testing

A technology of strength test and installation device, applied in the direction of measuring device, workpiece clamping device, instrument, etc., can solve the problems of lack of versatility, waste of manpower and material resources, etc., to achieve strong versatility, improved versatility, and improved test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with the drawings:

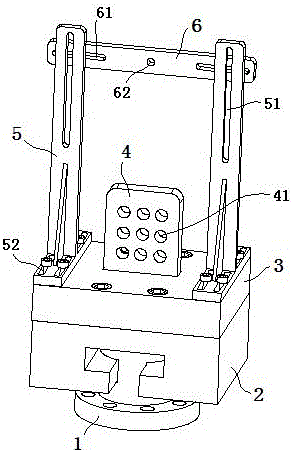

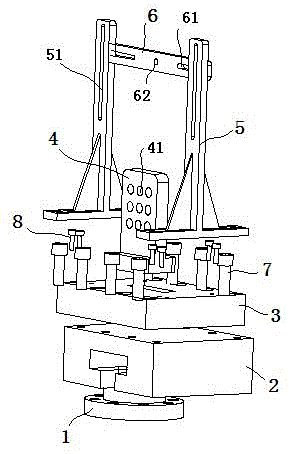

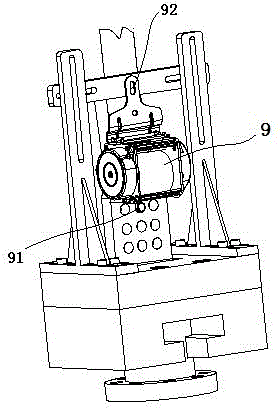

[0035] Figure 1 to Figure 4 A retractor installation device for strength testing is shown, including a connecting plate 1, a bottom plate 2, a fixing hole mounting bracket 3, a fixing hole mounting plate 4, a positioning hole mounting bracket 5 and a positioning hole mounting plate 6. The bottom plate 2 is arranged on the connecting plate 1, the fixing hole mounting bracket 3 is connected to the bottom plate 2 by a number of first bolts 7, and the fixing hole mounting plate 4 is inserted into the fixing hole mounting bracket 3. There are two positioning hole mounting brackets 5, and the two positioning hole mounting brackets 5 are symmetrically arranged at the left and right ends of the fixing hole mounting bracket 3. The positioning hole mounting plate 6 is cross-armed on the two positioning hole mounting brackets 5.

[0036] The connecting plate 1 is fixedly connected by bolts and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com