Novel full-automatic paper cutter

A fully automatic, paper cutter technology, applied in metal processing and other directions, can solve the problems of inability to perform automatic operations and high labor intensity of operators, and achieve the effect of saving manpower, high cutting efficiency and accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

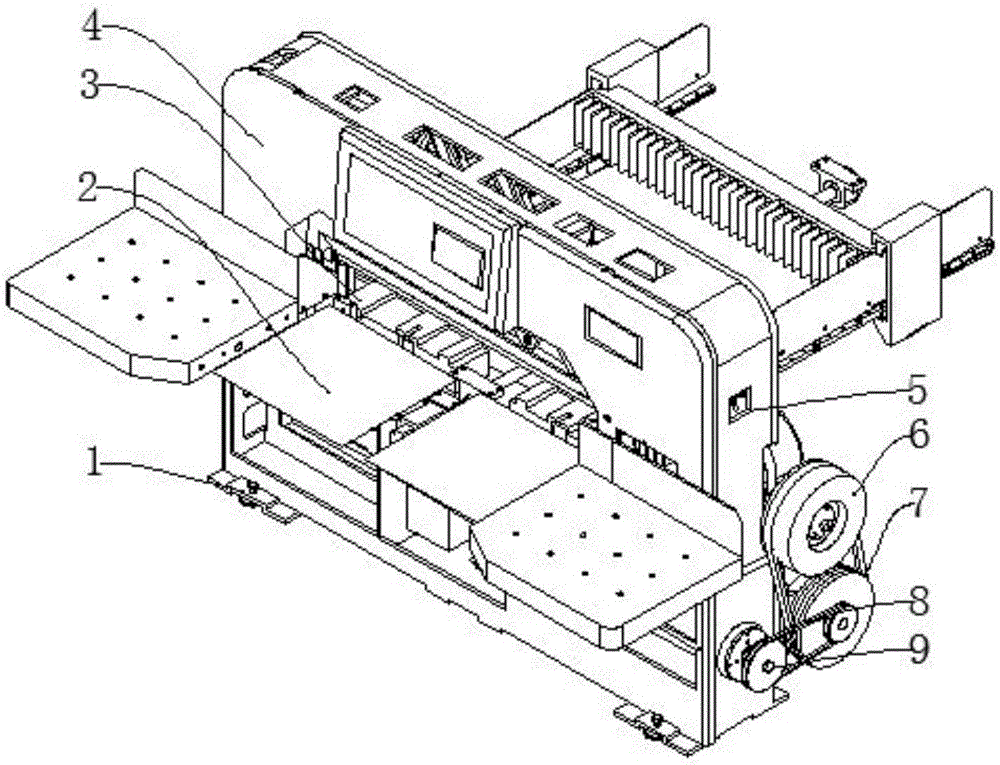

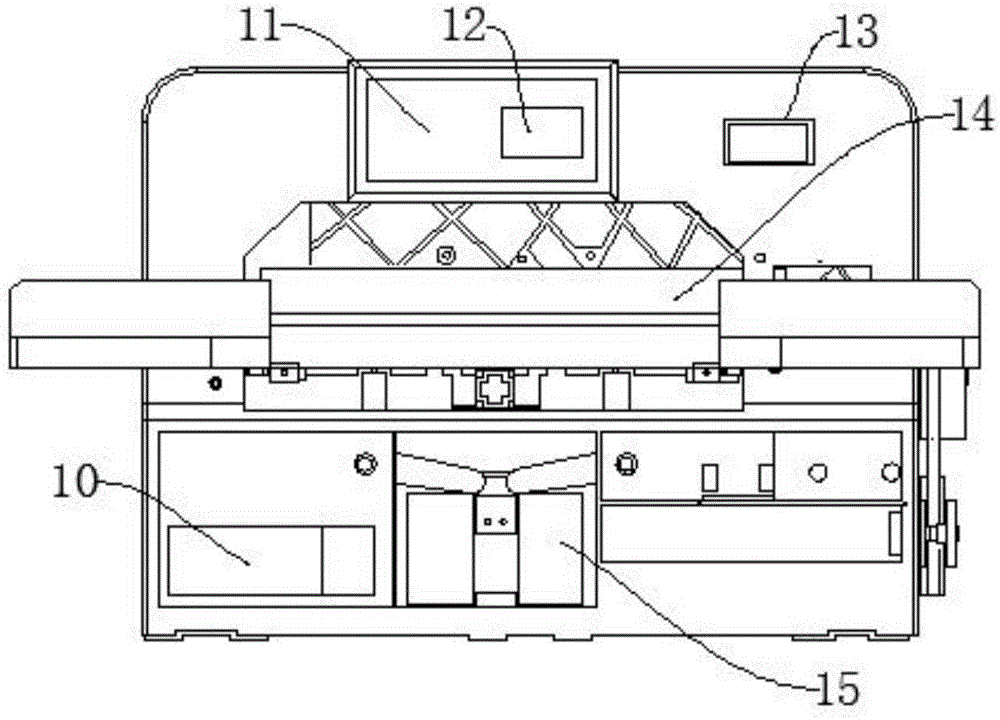

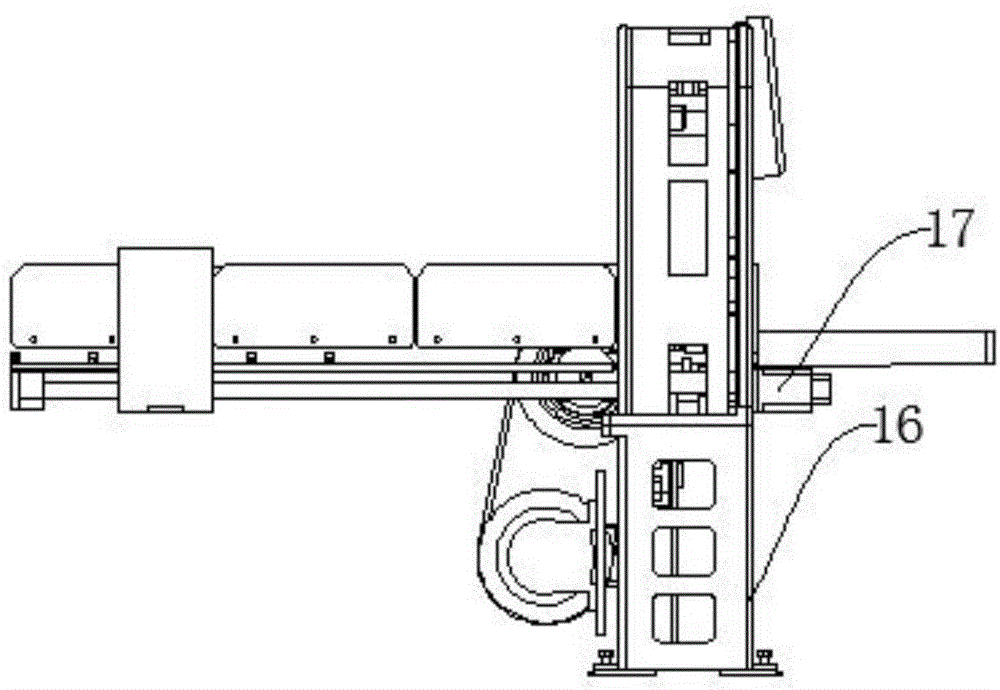

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Such as Figure 1-Figure 4 As shown, a new type of fully automatic paper cutter includes a casing 4, a cutting table 3, a propeller 19, and a control panel 11. A bracket 16 is arranged below the casing 4, and the bracket 16 is used to support the main structure of the equipment. , the fixed foot 1 is installed under the support 16, the fixed foot 1 is used to make the equipment contact with the ground better, the cutting table 3 is installed on the support 16, and the paper feeder is installed on the support 16 2, the paper feeder 2 is used to place the cut paper on the paper placement table 18, the paper placement table 18 is installed on the support 16, and the electrical box 10 is arranged below the support 16, so The electrical box 10 is used to install the electrical components required for the operation of the equipment. A lifter 15 is installed under the supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap