A film cutting machine with the function of protecting the cutter

A technology of film cutting machine and cutter, which is applied in metal processing and other directions, can solve the problems of cutter damage, inertial idling of film roll, etc., and achieve the effect of avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

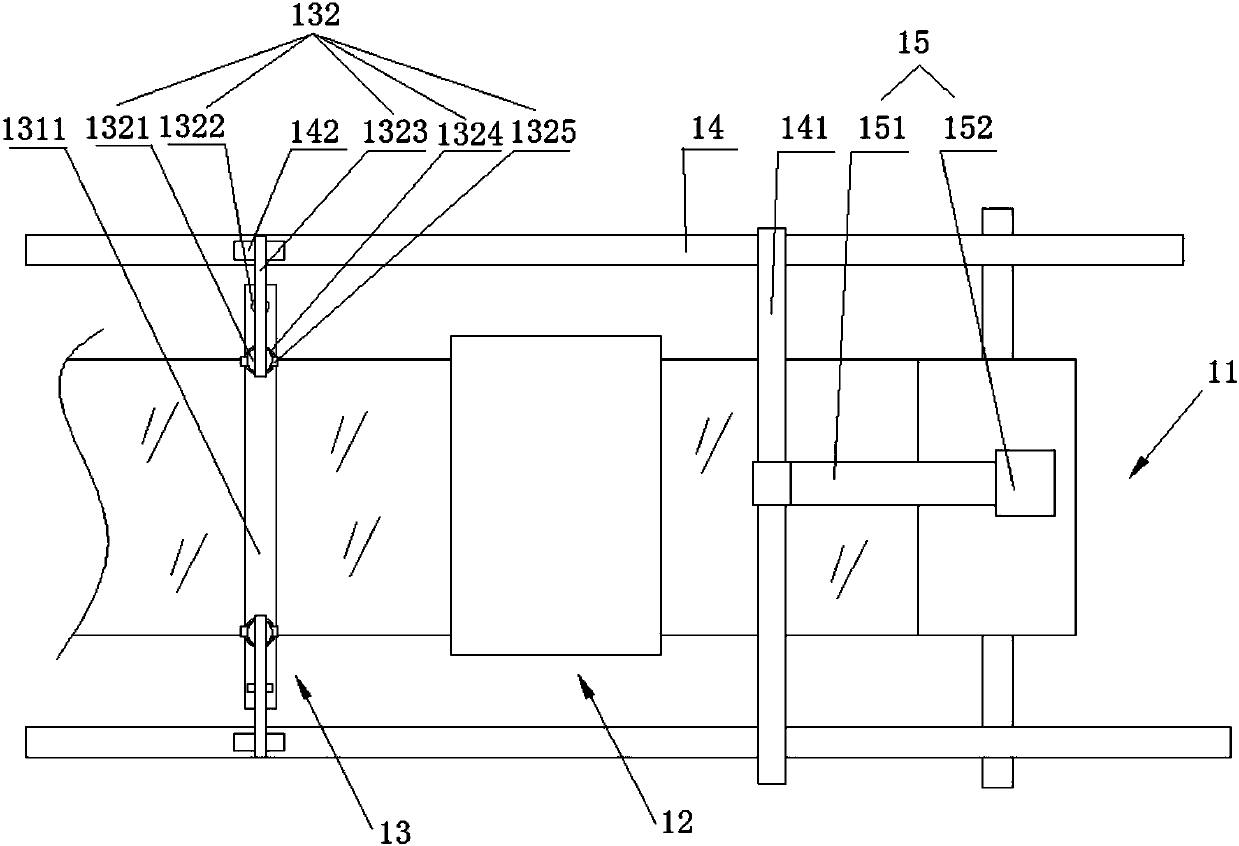

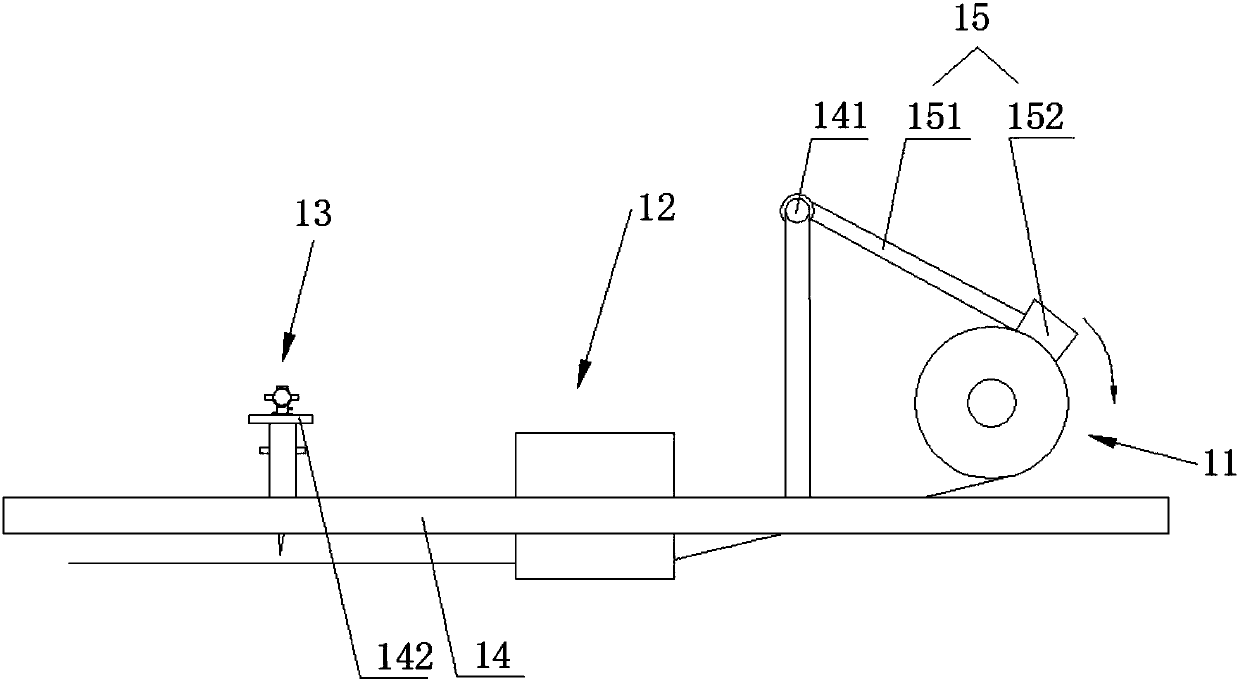

[0022] Such as figure 1 , figure 2 As shown, a film cutting machine with the function of protecting the cutter includes a frame; the frame 14 is provided with a film roll 11, a film feeding device 12, and a film cutting device 13; the film feeding device 12 cuts the film of the film roll 11 Is conveyed to the film cutting device 13; the frame 14 is also provided with a pressing device 15 that controls the inertial rotation speed of the film roll 11; the pressing device 15 is fixed on the frame 14 in rotation; the film cutting device 13 includes a cutting knife 131 and The limiting portion 132 of the cutting knife 131 is protected; the limiting portion 132 is fixed at one or both ends of the cutting knife 131.

[0023] In the present invention, a limiting portion 132 is provided at both ends of the cutting knife 131.

[0024] The film provided by the present invention is drawn out from below the film roll 11, and is conveyed to the film cutting device 13 through the film feeding de...

Embodiment 2

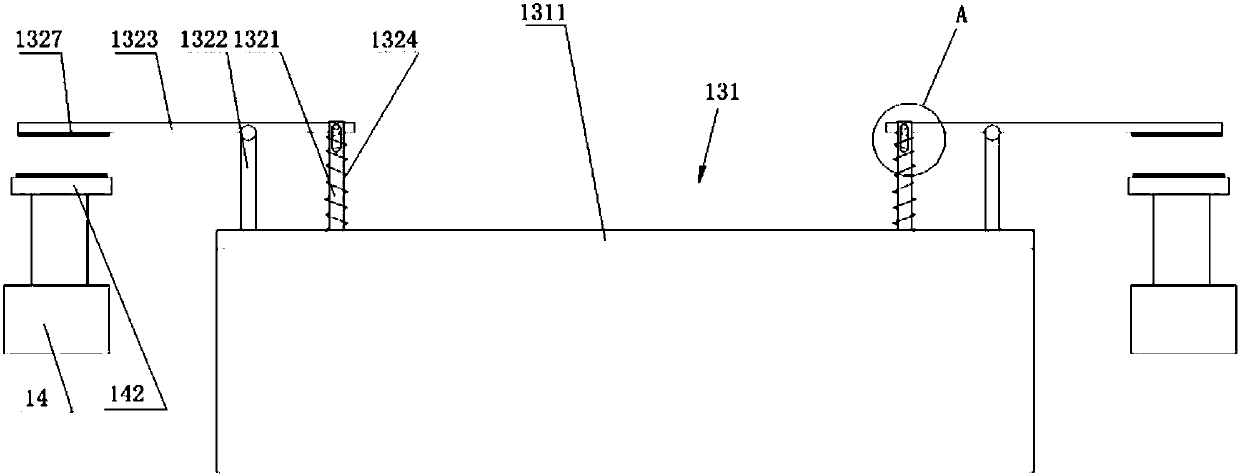

[0030] Such as image 3 , Figure 4 As shown, as a preferred solution of Embodiment 1, in order to make the falling and resetting process of the cutter 131 more gentle, the limit rod 1323 of the present invention is connected with the first vertical rod 1321 and the second vertical rod 1322 by rotation. Specifically: the upper end of the first vertical rod 1321 has a U-shaped groove, and waist-shaped holes 1326 are formed on the two side walls of the U-shaped groove; the end of the limit rod 1323 is provided with a through hole; the limit rod 1323 is clamped in the U shape In the groove and fixed by the pin 1325. The rod body of the limit rod 1323 and the second vertical rod 1322 may be connected by rotation. The limiting rod 1323 is parallel to the rotation axis of the first vertical rod 1321 and the rotation axis of the second vertical rod 1322 and cuts perpendicular to the cutting surface of the cutter 131. When the cutter 131 is lowered, the limit rod 1323 is restricted b...

Embodiment 3

[0032] Such as Figure 4 As shown, as a preferred solution of Embodiment 2, the present invention further includes an elastic member 1324 on the rod body of the first vertical rod 1321; the upper and lower ends of the elastic member 1324 are respectively restricted by the knife back 1311 and the limit rod 1323, As a result, the elastic member 1324 pushes the pin shaft 1325 on the uppermost part of the waist hole. The elastic member 1324 provided by the present invention is a compression spring or other elastic components with equivalent functions. With this design, when the cutter 131 is lowered, the free end of the limit rod 1323 is lifted by the baffle 142. With the second vertical rod 1322 as the fulcrum, the connecting end of the limit rod 1323 and the first vertical rod 1321 is lowered and pressed The spring is compressed and the compression spring is compressed. After the film is cut, the compression spring is reset, which drives the cutter 131 to quickly reset, avoidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com