Adjustable square pipe fixing rack for winding pipes

A technology of winding tube and fixing frame, applied in the field of adjustable winding tube square tube fixing frame, can solve the problems of not being able to adjust the fixing frame anytime and anywhere, deformation of the fixing frame, low work efficiency, etc., so as to improve production efficiency and production stability stability, reliable expansion and contraction, reducing deformation and the effect of equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

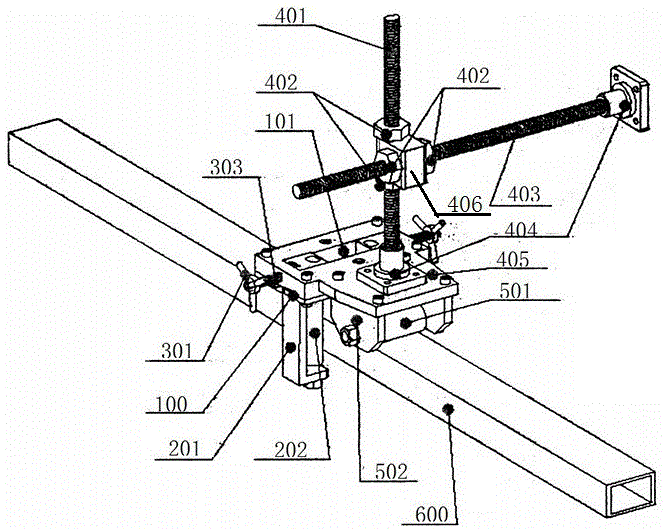

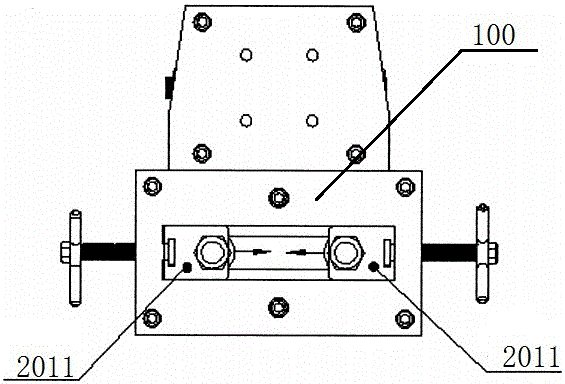

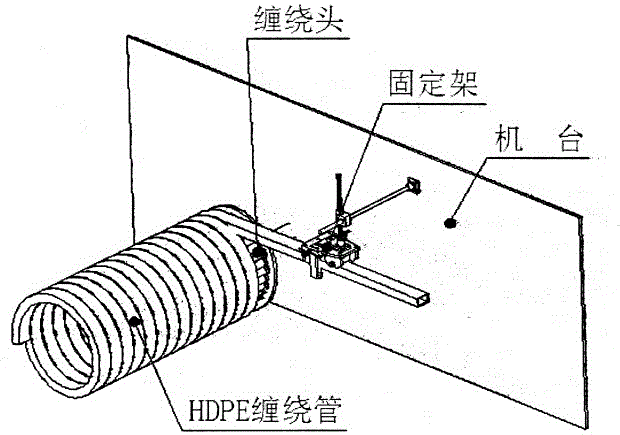

[0026] Such as Figure 1~3 As shown, an adjustable winding pipe square pipe fixing frame, the fixing clip is fixed on the machine table, including a support plate 100, and a pair of support plates 100 are provided on the support plate 100 to clamp the opposite pipe 600 in the horizontal direction. The clamping limit wheel 202 of the limit, and the compression limit wheel 501 that can be pressed and limited to the opposite pipe 600 in the vertical direction, the clamping limit wheel 202 is connected with a first adjustment mechanism to realize the clamping limit. Horizontal adjustment of the position wheel 202 , the support plate 100 is connected with a second adjustment mechanism to realize the horizontal and vertical adjustment of the support plate 100 .

[0027] The clamping limit wheel 202 is installed on the U-shaped support frame 201, one end of the U-shaped support frame 201 is provided with a clamping part 2011, and the support plate 100 is provided with a card slot 101...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap