Wine vacuum bottle cork

A technology for vacuum bottle and red wine, which is applied to packaging, sealing plug, bottle filling and other directions under vacuum/special atmosphere, can solve problems such as affecting the taste and quality of red wine, worsening taste of red wine, and preservation of red wine, etc. The effect of maintaining taste and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

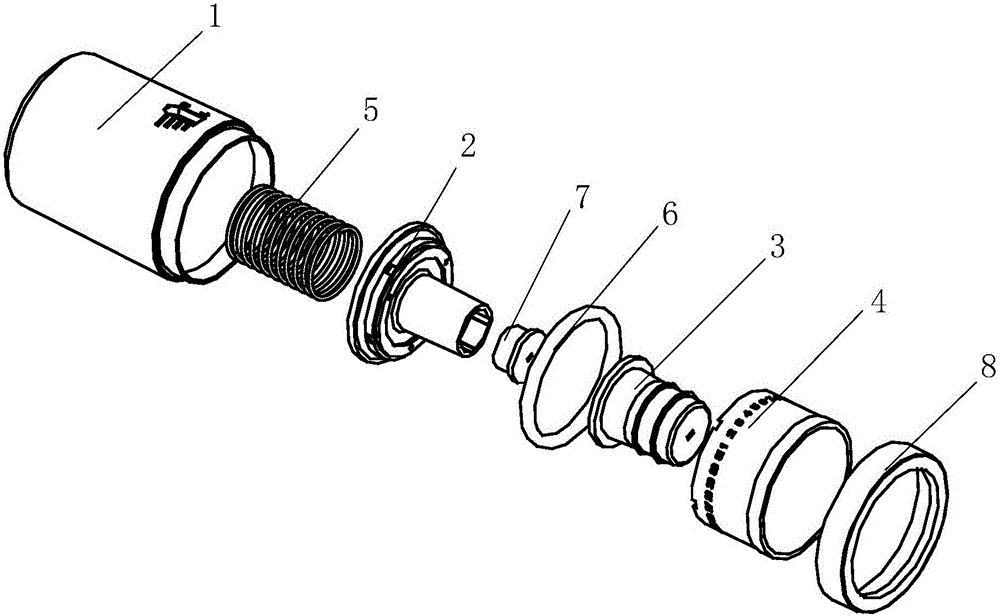

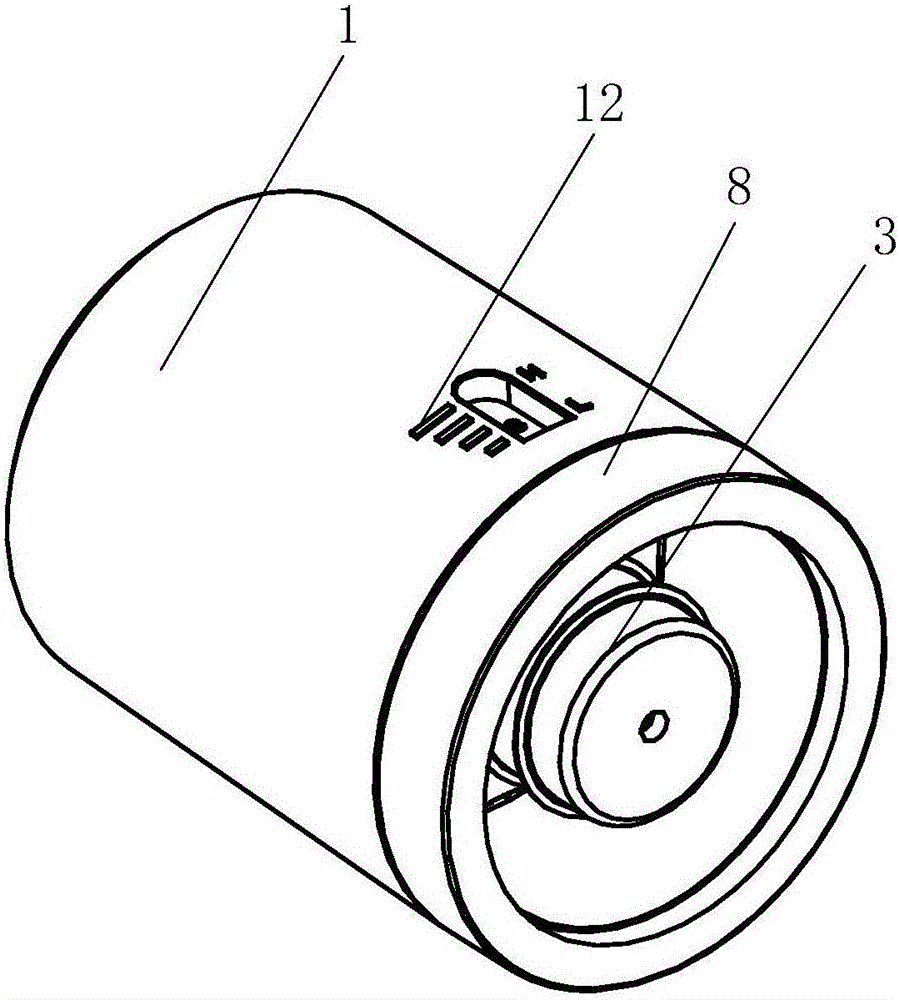

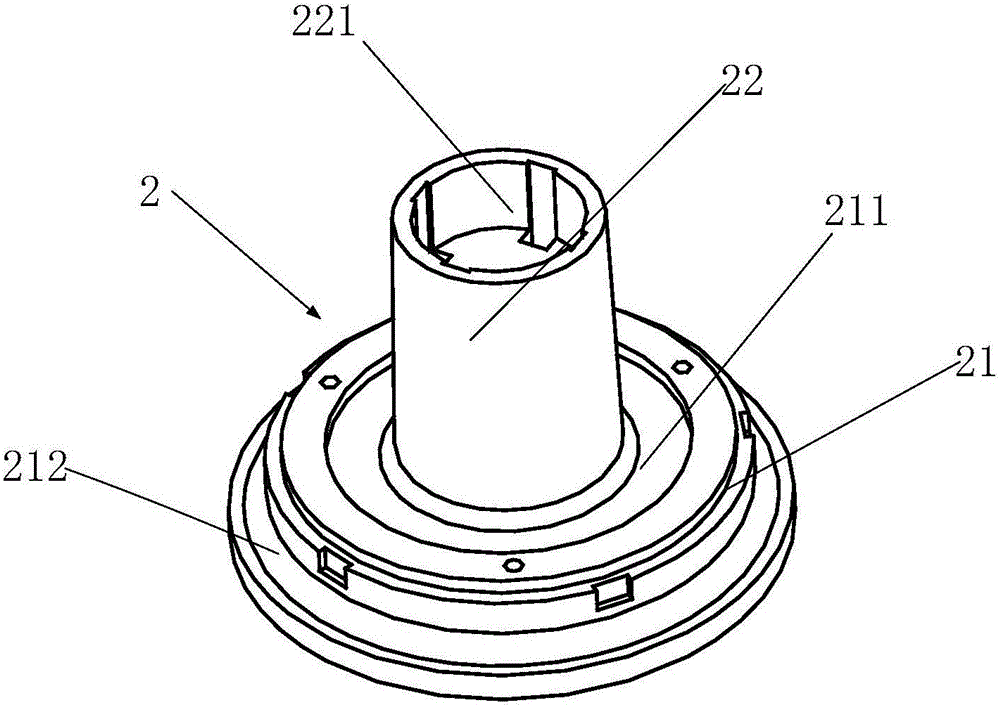

[0034] like Figures 1 to 7 As shown, the present embodiment includes a red wine vacuum cork, which includes a housing 1, a fixed seat 2, a rubber stopper 3, and an elastic member 5, the rubber stopper 3 is fixedly mounted on the fixed seat 2, and the fixed seat 2 Installed together with the rubber stopper 3 inside the casing 1, an elastic member 5 is installed between the fixing seat 2 and the casing 1, the rubber stopper 3 is used to insert into the mouth of the wine bottle, the rubber stopper 3 is provided with an air vent 33, and the casing 1 An opening is provided on the top, and the exhaust hole 33 communicates with the inside of the housing 1 .

[0035] Insert the rubber stopper 3 into the mouth of the wine bottle, and press the shell 1 to make the shell 1 follow the elastic member 5 to move relative to the fixed part, so that a negative pressure is generated inside the shell 1, and the air in the red wine bottle is discharged through the exhaust hole 33, Maintain a pa...

Embodiment 2

[0048] Such as Figures 1 to 7 As shown, this embodiment includes a red wine vacuum cork, including a housing 1, a fixed seat 2, a rubber stopper 3, a limit ring 4 and an elastic member 5, the rubber stopper 3 is fixedly installed on the center of the fixed seat 2, and the limit The position ring 4 is sleeved on the fixed seat 2, and the limit ring 4 is used to control the pressing depth of the rubber plug 3. The fixed seat 2, the rubber plug 3 and the limit ring 4 are installed inside the shell 1 together, and the fixed seat 2 and An elastic member 5 is installed between the shells 1, and the rubber stopper 3 is used to insert into the mouth of the wine bottle. The rubber stopper 3 is provided with an air vent 33, and the shell 1 is provided with an opening.

[0049] Insert the rubber stopper 3 into the mouth of the wine bottle, and press the shell 1 to make the shell 1 follow the elastic member 5 to move relative to the fixed part, so that a negative pressure is generated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com