A kind of unloading equipment for bagasse conveying belt

A conveyor belt and equipment technology, applied in the field of unloading equipment for bagasse conveyor belts, can solve the problems of no bagasse to burn in the boiler and affect the continuous and stable operation of the boiler, and achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Embodiments of the present invention provide a kind of unloading equipment for bagasse conveyor belt, comprising:

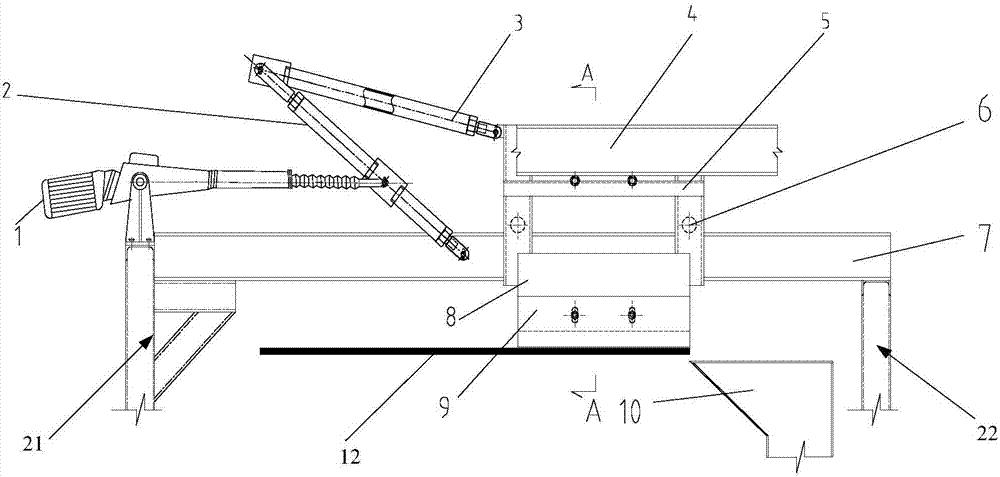

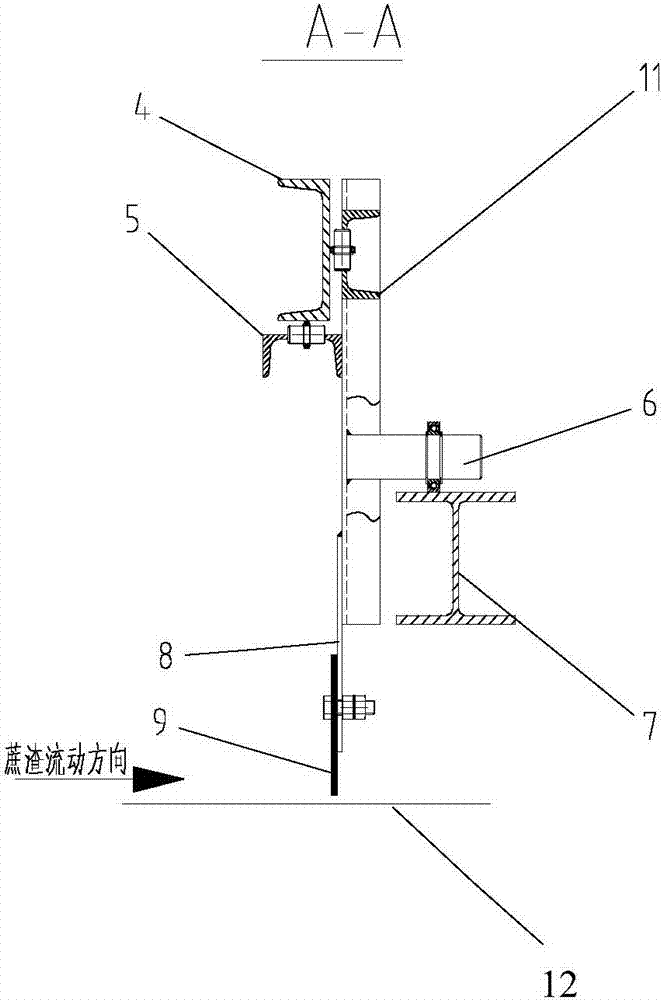

[0031] A guide rail spanning over the section of the belt 12;

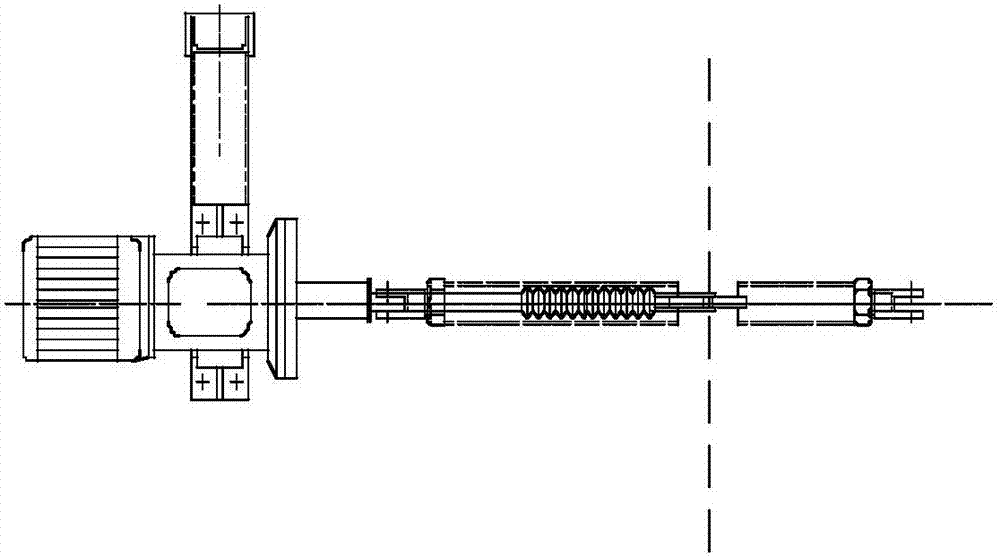

[0032] At a position close to one side end of the guide rail, a driving device 1 is installed, and the driving device 1 is connected with a link mechanism that moves above the cross section of the belt 12;

[0033] The link mechanism is fixedly connected with the unloading plate 8 moving along the guide rail;

[0034] A baffle 9 for blocking the bagasse from advancing and being introduced into the hopper 10 is installed on the discharge plate 8 .

[0035] In the scheme of the embodiment of the present invention, through the movement of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com