Conveniently swerved crane hook

A crane and hook technology, applied in the field of crane hooks that are easy to turn, can solve problems such as difficult rotation, and achieve the effects of easy rotation direction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

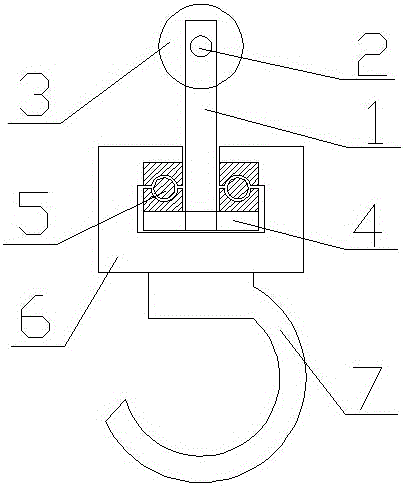

[0011] Such as figure 1 As shown, the present invention discloses a crane hook that is easy to turn, including: a main force rod 1, a pulley shaft 2, a pulley 3, a load bearing plate 4, a thrust ball bearing 5, a load bearing shell 6, and a hook 7. The main force rod 1 is a cylindrical structure, and the upper part of the main force pole 1 is provided with a pulley groove and a pulley shaft hole, the pulley shaft 2 is installed in the pulley shaft hole on the upper part of the main force pole 1, and the pulley 3 is installed on the pulley shaft 2 , the load-bearing plate 4 is fixed on the lower end of the main rod 1 by welding, and the thrust ball bearing 5 is installed in the middle of the connecting surface between the load-bearing plate 4 and the load-bearing shell 6, and the load-bearing shell 6 is the upper part of the cylindrical cavity structure There are openings installed on the outside of the load-bearing plate 4, and the described hook 7 is fixed on the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com