Integrated oil separation hoisting equipment

An integrated, oil-separating technology, used in water/sewage treatment equipment, liquid separation, grease/oily substance/float removal devices, etc. The oil effect is obvious, the heating and heat preservation links are reduced, and the labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

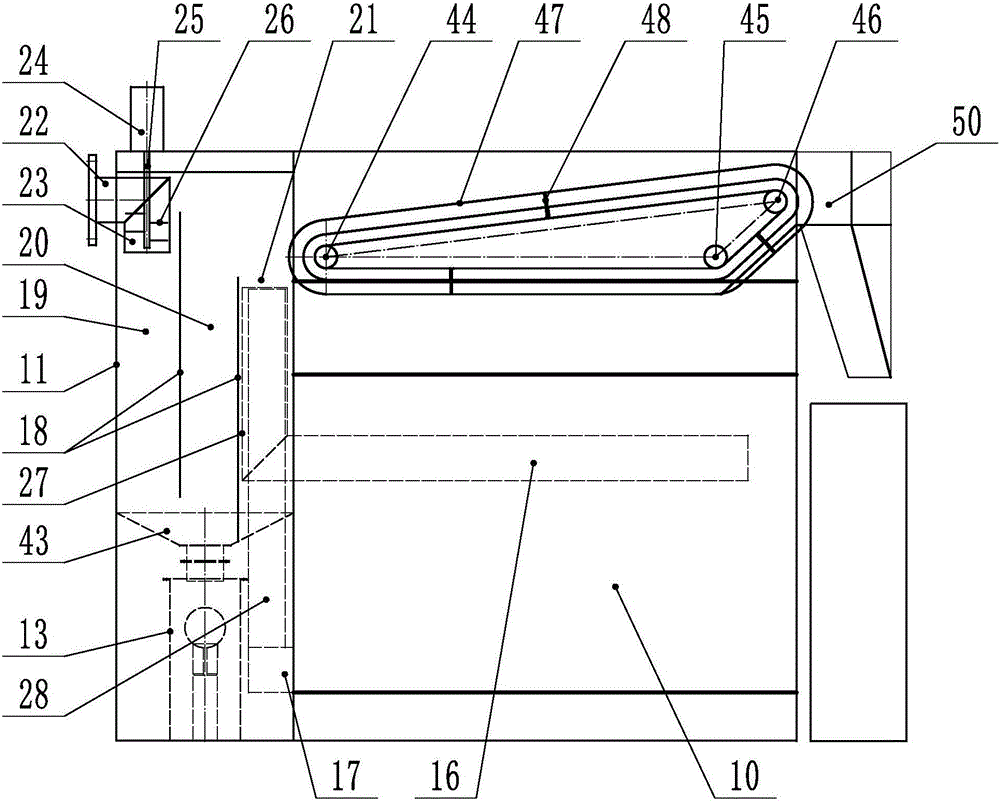

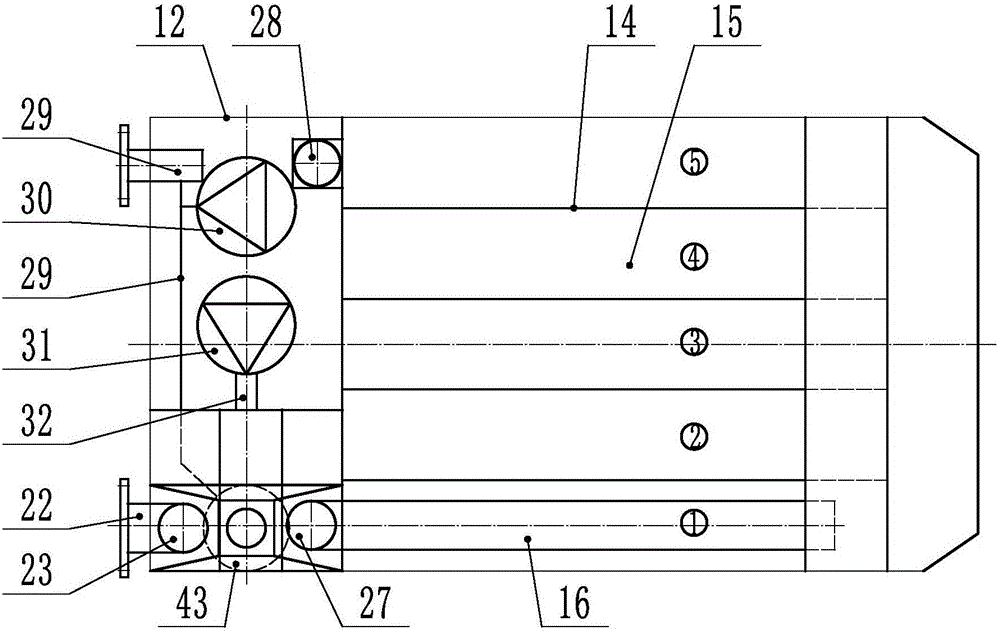

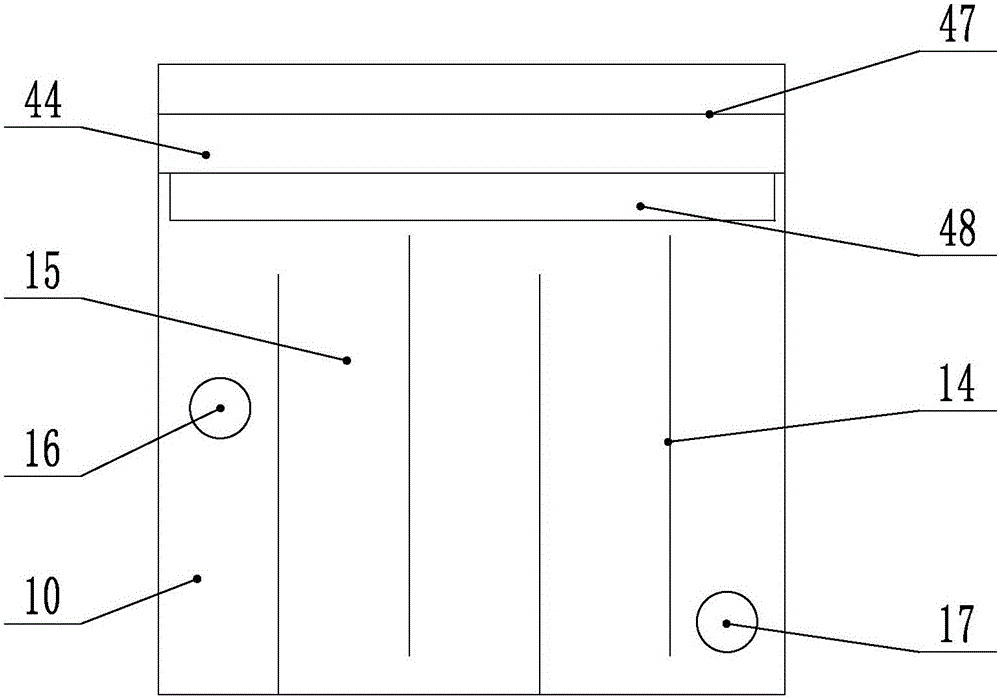

[0050] refer to Figure 1~6 , is an integrated oil-separating lifting device disclosed in the present invention, including an oil-separating chamber 10, a solid-liquid separation chamber 11, a sewage lifting chamber 12, a backwash sewage discharge chamber 13, an oil-separating chamber 10, a solid-liquid separation chamber 11, a sewage Both the lifting chamber 12 and the backwashing sewage chamber 13 are designed with a fully enclosed structure. According to the working principle of the whole equipment, the liquid with solid dirt is first transported to the solid-liquid separation chamber 11 for solid-liquid separation, and the separated liquid enters the oil separation chamber 10, and then enters the sewage lifting chamber 12, and the sewage is lifted Part of the liquid in the chamber 12 is directly discharged, and the other part is pumped into the backwash sewage chamber 13 through the submersible pump. The solid waste separated from the solid-liquid separation chamber 11 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com