A composite reinforced alkali-activated slag mortar board and its preparation method

A composite reinforcement, slag sand technology, applied in the field of building materials, can solve the problems of fabric debonding and peeling, reducing bearing capacity, etc., to achieve the effect of less environmental pollution, easy production, and mature production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method comprises the following steps:

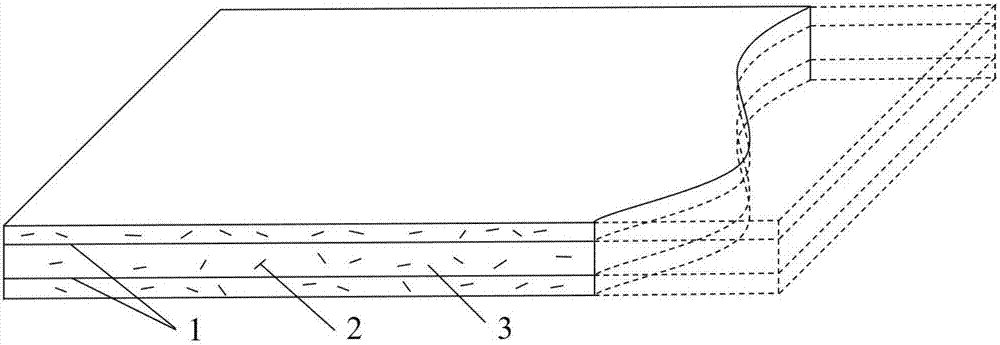

[0038] The first step: according to the product performance requirements, select the appropriate number of layers, spacing, thickness of upper and lower protective layers of continuous carbon fiber fabric, type of chopped fiber, geometric size, volume fraction and thickness of the plate;

[0039] Step 2: According to the parameters selected in the first step, fix the continuous carbon fiber fabric in a suitable mold and apply a certain tension to each layer of fabric to maintain a flat state;

[0040] The third step: according to the product performance requirements, select the appropriate parameters of the alkali-activated slag mortar mix ratio, such as: the type of cementitious material, the alkali content and modulus of the alkali activator, water-cement ratio, bone-cement ratio, etc.;

[0041] Part 4: According to the alkali-activated slag mortar mix parameters selected in the third step, mix the accurately wei...

Embodiment 1

[0044] Composite reinforced alkali activated slag mortar board, its composition is as follows:

[0045] 1. The reinforcement material is continuous carbon fiber fabric and chopped polypropylene fiber. The tensile strength of the continuous carbon fiber fabric is 3200MPa, the elastic modulus is 215GPa, and the elongation is 2.0%. The number of laying layers is 2 layers, the layer spacing is 10mm, and the thickness of the upper and lower protective layers is 10mm; , with a diameter of 25 μm and a volume fraction of 1.0%;

[0046] 2. The thickness of the board is 20mm;

[0047] 3. The cementitious material in the alkali-activated slag mortar is composed of S95 grade fine-grained blast-furnace slag powder, and the content of the fine-grained blast-furnace slag powder accounts for 100% of the mass of the cementitious material;

[0048] 4. The alkali activator in the alkali-activated slag mortar is water glass and sodium hydroxide, the alkali content in the alkali activator is 5.0...

Embodiment 2

[0056] Composite reinforced alkali activated slag mortar board, its composition is as follows:

[0057] 1. The reinforcement material is continuous carbon fiber fabric and chopped polypropylene fiber. The tensile strength of the continuous carbon fiber fabric is 3100MPa, the elastic modulus is 210GPa, and the elongation is 2.0%. The number of laying layers is 3 layers, the layer spacing is 5mm, and the thickness of the upper and lower protective layers is 10mm; , with a diameter of 25 μm and a volume fraction of 1.5%;

[0058] 2. The thickness of the board is 35mm;

[0059] 3. The cementitious material in the alkali-activated slag mortar is composed of S95 fine-grained blast furnace slag powder and metakaolin. The content of finely ground blast furnace slag powder accounts for 90% of the mass of the cementitious material, and metakaolin accounts for the mass of the cementitious material. 10%;

[0060] 4. The alkali activator in the alkali-activated slag mortar is water glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com