A treatment method for the biological simultaneous removal of high iron and high manganese in underground drinking water under low temperature conditions

A low-temperature condition and treatment method technology, applied in the direction of contaminated groundwater/leachate treatment, multi-stage water treatment, water treatment parameter control, etc., can solve the problems of high removal cost and low removal rate of iron and manganese, and achieve utilization efficiency The effect of low cost, low cost and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

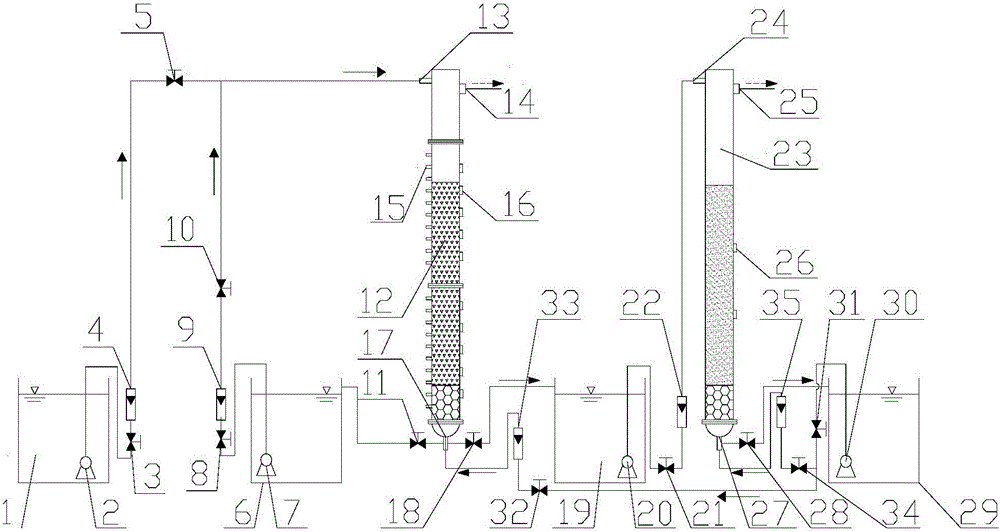

[0030] Specific implementation mode one: combine figure 1 , This embodiment is a treatment method for biologically synchronous removal of high iron and high manganese in underground drinking water under low temperature conditions, which is specifically completed according to the following steps:

[0031] 1. Loading filter material: Add carbonized rice husk particles and support material I to the 1# filter column (12) of the biological synchronous removal of high iron and high manganese device from top to bottom to obtain the filter material layer and support layer I. The thickness of material layer is 150cm~180cm, and the thickness of support layer I is 8cm~10cm. Add sterilizing activated carbon and support material II to 2# filter column (23) to obtain adsorption filter material layer and support layer II. The thickness of the filter material layer is 120cm-180cm, and the thickness of the supporting layer II is 8cm-10cm;

[0032] 2. Start-up phase:

[0033] ①. Close the bac...

specific Embodiment approach 2

[0051] Specific implementation mode two: combination figure 1The difference between this embodiment and the specific embodiment one is: the bio-synchronous removal of high-iron and high-manganese device described in step one is composed of the aeration tank (1), the 1# filter column inlet water submersible pump (2), and the 1# filter Column water inlet control valve Ⅰ (3), 1# filter column water inlet flow meter (4), 1# filter column water inlet control valve Ⅱ (5), bacteria solution pool (6), bacteria solution inlet submersible pump (7 ), bacteria solution inlet control valve Ⅰ (8), bacteria solution inlet water flowmeter (9), bacteria solution water inlet control valve II (10), bacteria solution water outlet control valve (11), 1# filter column (12) , 1# filter column water inlet (13), 1# filter column overflow port (14), 1# filter column sampling port (15), 1# filter column intake port (16), 1# filter column outlet ( 17), 1# filter column water outlet control valve (18), i...

specific Embodiment approach 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the supporting material I described in step 1 is a mixture of pebbles and manganese sand, and the pebbles in the mixture of pebbles and manganese sand are used as supports , manganese sand as filler. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com