Fabric with crinkle surface structures

A fabric and crepe surface technology, applied in the field of textile fabrics, can solve the problems of hemp fiber fabrics such as rough hand feeling, poor moisture absorption and moisture conductivity, and not smooth to wear, and achieve good decorative and beautifying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

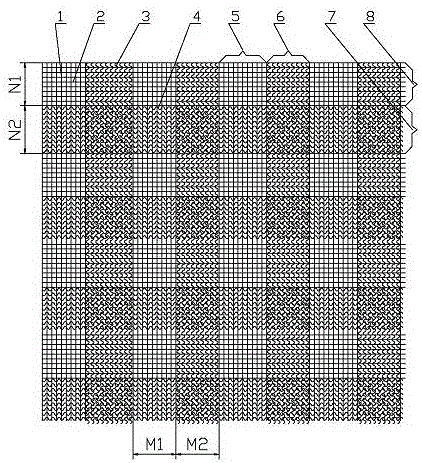

[0015] exist figure 1 In the shown fabric with crepe surface structure, warp yarns include basic warp yarn 1 and crepe warp yarn 3, basic warp yarn 1 is elastic yarn, crepe warp yarn 3 is made of pure cotton yarn, several basic warp yarns 1 form basic warp yarn segment 5, and several crepe warp yarns The grain warp yarn 3 constitutes the crepe warp yarn section 6, the ratio M1 / M2 of the width M1 of the basic warp yarn section 5 to the width M2 of the crepe warp yarn section 6 is 0.5 to 1.5, and the basic warp yarn section 5 and the crepe warp yarn section 6 alternate in the fabric Arrangement; weft yarns include basic weft yarn 2 and crepe weft yarn 4, basic weft yarn 2 is elastic yarn, crepe weft yarn 4 adopts pure cotton yarn, several basic weft yarns 2 form basic weft yarn section 8, and some crepe weft yarns 4 form crepe weft yarn section 7 The ratio N1 / N2 of the width N1 of the basic weft yarn segment 8 to the width N2 of the crepe weft yarn segment 7 is 0.5 to 1.5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com