Recovery and separation kettle and recovery and separation method for supercritical CO2 dyeing gas-solid separation

A technology of gas-solid separation and separation method, which is applied in the direction of separation method, chemical instrument and method, solvent dyeing, etc. It can solve the problems of affecting dyeing effect, water separation, pollution, etc., and achieve the effect of improving purity and dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

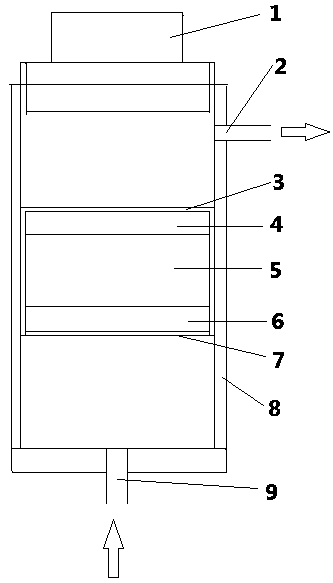

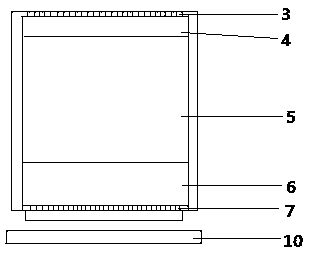

[0034] Supercritical CO using 5A grade molecular sieve 2 The recovery and separation kettle for dyeing gas-solid separation is a method for recovering and separating waste gas. This method uses supercritical CO 2 After anhydrous dyeing, the exhaust gas with a large amount of red disperse dyes, fabric impurities and moisture passes through the separation tank equipped with 5A grade molecular sieve 5, and the pressure of the gas suddenly drops from 20MPa to less than 7MPa. After the high-speed airflow passes through the lower layer of sponge 6, the airflow changes from one bundle to multiple bundles, and the speed will decrease sharply at the same time. In this layer, fabric impurities and moisture with large particle diameters will be trapped and isolated. Immediately afterwards, when the air flow enters the molecular sieve 5 with strong adsorption and large specific surface area, the dye and remaining moisture in the air flow will be fully absorbed by the molecular sieve 5 . ...

Embodiment 2

[0036] Supercritical CO using grade 4A molecular sieves 2 The recovery and separation kettle for dyeing gas-solid separation is a method for recovering and separating waste gas. This method uses supercritical CO 2 After anhydrous dyeing, the exhaust gas with a large amount of blue disperse dyes, fabric impurities and moisture passes through the separation tank equipped with 4A grade molecular sieve 5, and the pressure of the gas suddenly drops from 20MPa to less than 7MPa. After the high-speed airflow passes through the lower layer of sponge 6, the airflow changes from one bundle to multiple bundles, and the speed will decrease sharply at the same time. In this layer, fabric impurities and moisture with large particle diameters will be trapped and isolated. Immediately afterwards, when the air flow enters the molecular sieve 5 with strong adsorption and large specific surface area, the dye and remaining moisture in the air flow will be fully absorbed by the molecular sieve 5 ...

Embodiment 3

[0038] Supercritical CO using 3A grade molecular sieve 2 The recovery and separation kettle for dyeing gas-solid separation is a method for recovering and separating waste gas. This method uses supercritical CO 2 After anhydrous dyeing, the exhaust gas with a large amount of yellow disperse dyes, fabric impurities and moisture passes through the separation tank equipped with 3A grade molecular sieve 5, and the pressure of the gas suddenly drops from 20MPa to less than 6MPa. After the high-speed airflow passes through the lower layer of sponge 6, the airflow changes from one bundle to multiple bundles, and the speed will decrease sharply at the same time. In this layer, fabric impurities and moisture with large particle diameters will be trapped and isolated. Next, when the air flow enters the molecular sieve 5 with strong adsorption and large specific surface area, the dye and remaining moisture in the air flow will be fully absorbed by the molecular sieve. Afterwards, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com