A prefabricated coastal anti-wave dike

A prefabricated, embankment technology, applied in the direction of coastline protection, etc., can solve the problems of insufficient impact resistance and incapable of waves, and achieve the effects of releasing and alleviating the impact of waves, shortening the construction period, and improving the level of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

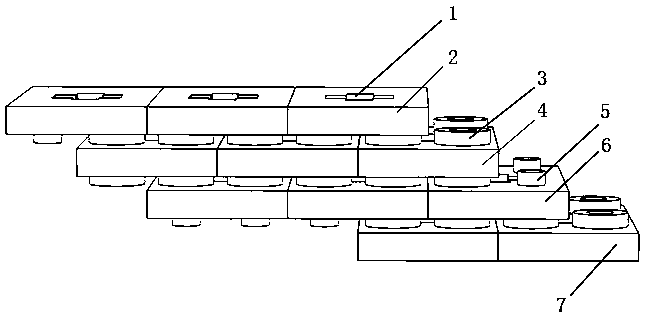

[0027] Such as figure 1 , 2 , 3, 4 and 5 show a kind of prefabricated coastal anti-wave dam, which is characterized in that the structure is as follows: a plurality of prefabricated concrete dam blocks are stepped and stacked up to the design height, and the concrete dam blocks Body is divided into A, B, C, D 6, 4, 7, 2 four types.

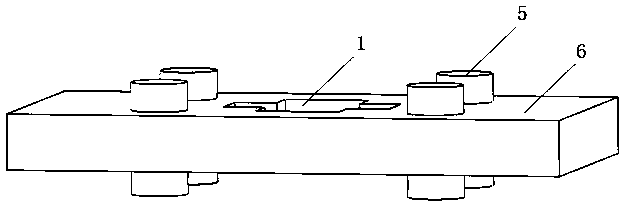

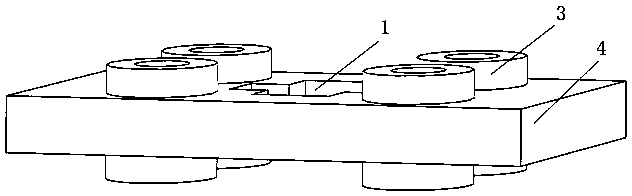

[0028] The above-mentioned four types of concrete embankment blocks A, B, C, D 6, 4, 7, and 2 are all rectangular, and a cross-shaped through hole 1 is provided in the middle.

[0029] The above-mentioned A-type 6 concrete embankment blocks are respectively provided with four cylindrical A protrusions 5 at the matching positions near the four corners on the upper and lower surfaces.

[0030] The above-mentioned B-type 4 concrete embankment blocks are respectively provided with four hollow cylindrical B protrusions 3 at the fitting positions near the four corners on the upper and lower surfaces, and the hollow shape is the same as the shape of th...

Embodiment 2

[0034] The above-mentioned concrete dam block of type A 6 is provided with four square column-shaped A protrusions 5 at the matching positions near the four corners on the upper and lower surfaces, and the above-mentioned concrete dam block of type C 7 is on one surface. Four hollow square-column-shaped B protrusions 3 are respectively provided at the matching positions near the four corners, and the hollow shape matches the shape and size of the A protrusion 5 . The rest are the same as in Embodiment 1, and will not be repeated.

[0035] Concrete construction process of the present invention:

[0036] During construction, several C-type 7 concrete embankment blocks are closely adjacent to each other and laid on the bottom. Then, by inserting the four cylindrical A protrusions 5 on the lower surface of the A-type 6 concrete embankment block into the four inner hollow cylindrical B protrusions 3 of two adjacent C-type 7 concrete embankment blocks , completed the assembly betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com