Double-layer square steel tube sound insulation wall structure and mounting method thereof

A sound insulation wall, double-layer technology, applied in the field of architectural decoration, can solve the problems of inability to meet other requirements of architectural decoration, poor strength and stability of light steel keels, and difficulty in adapting to on-site installation patterns, etc., to increase the sound insulation effect, avoid on-site welding, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

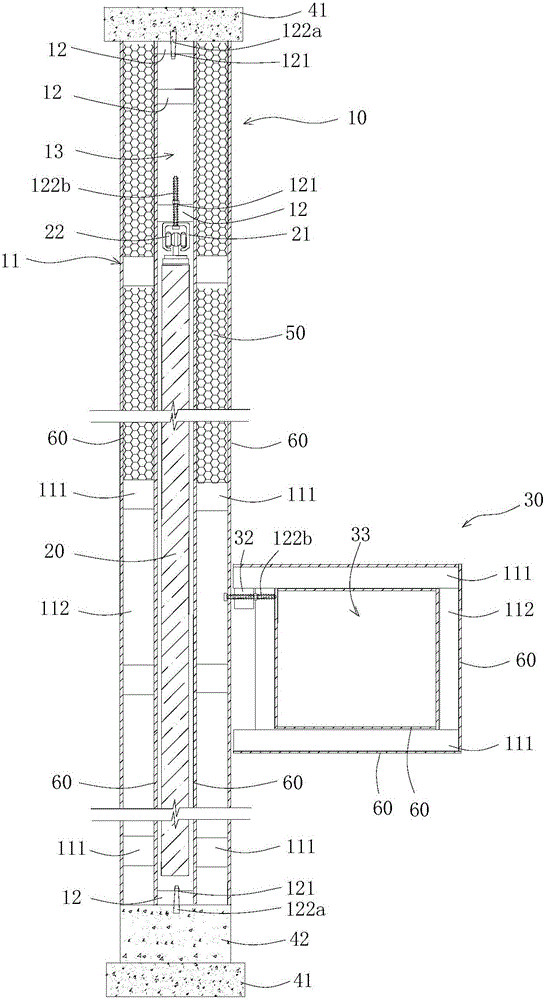

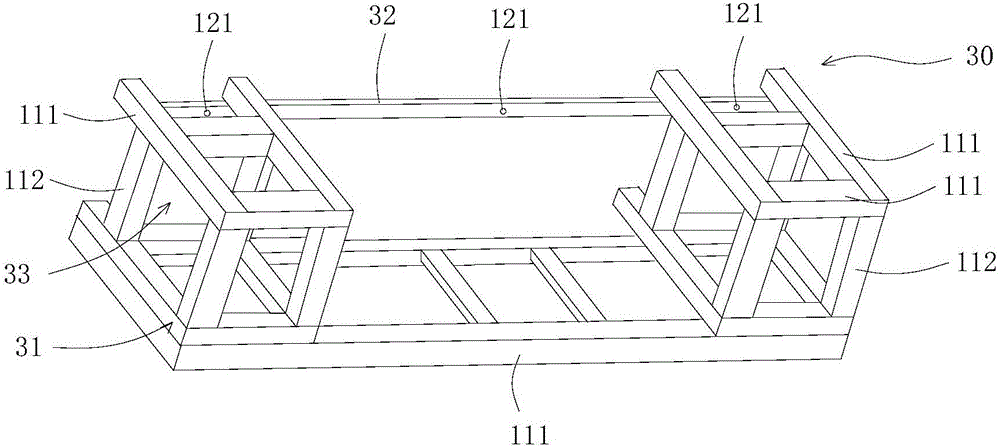

[0041] Such as figure 1 As shown, the present invention relates to a double-layer square steel sound insulation wall structure, comprising a wall foundation frame 10, a sliding door 20, and a sink bracket 30, and the wall foundation frame 10 includes two rows of square steel frame frames arranged in parallel and at intervals 11. The two rows of square steel frameworks 11 are fixedly connected by a plurality of crosspieces 12 arranged at intervals in parallel, and an air layer 13 is formed in the middle; the single sliding door 20 is fixed on the lower surface of the crosspiece 12 at a suitable position of the air layer 13, The assembled washbasin bracket 30 is hung on the bolts 122b on the side of the wall foundation frame 10 .

[0042] A through hole 121 is provided on the crosspiece 12 at the top of the wall foundation skeleton 10, and the expansion bolt 122a is inserted into the original structure floor 41 through the through hole 121, so that the upper end of the wall foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com