A ceiling wire release device

A pay-off device and coil technology, applied in the field of measurement, can solve problems such as affecting the construction period, heavy workload, and missed work by operators, and achieve the effects of saving equipment investment, reasonable structure, and speeding up construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

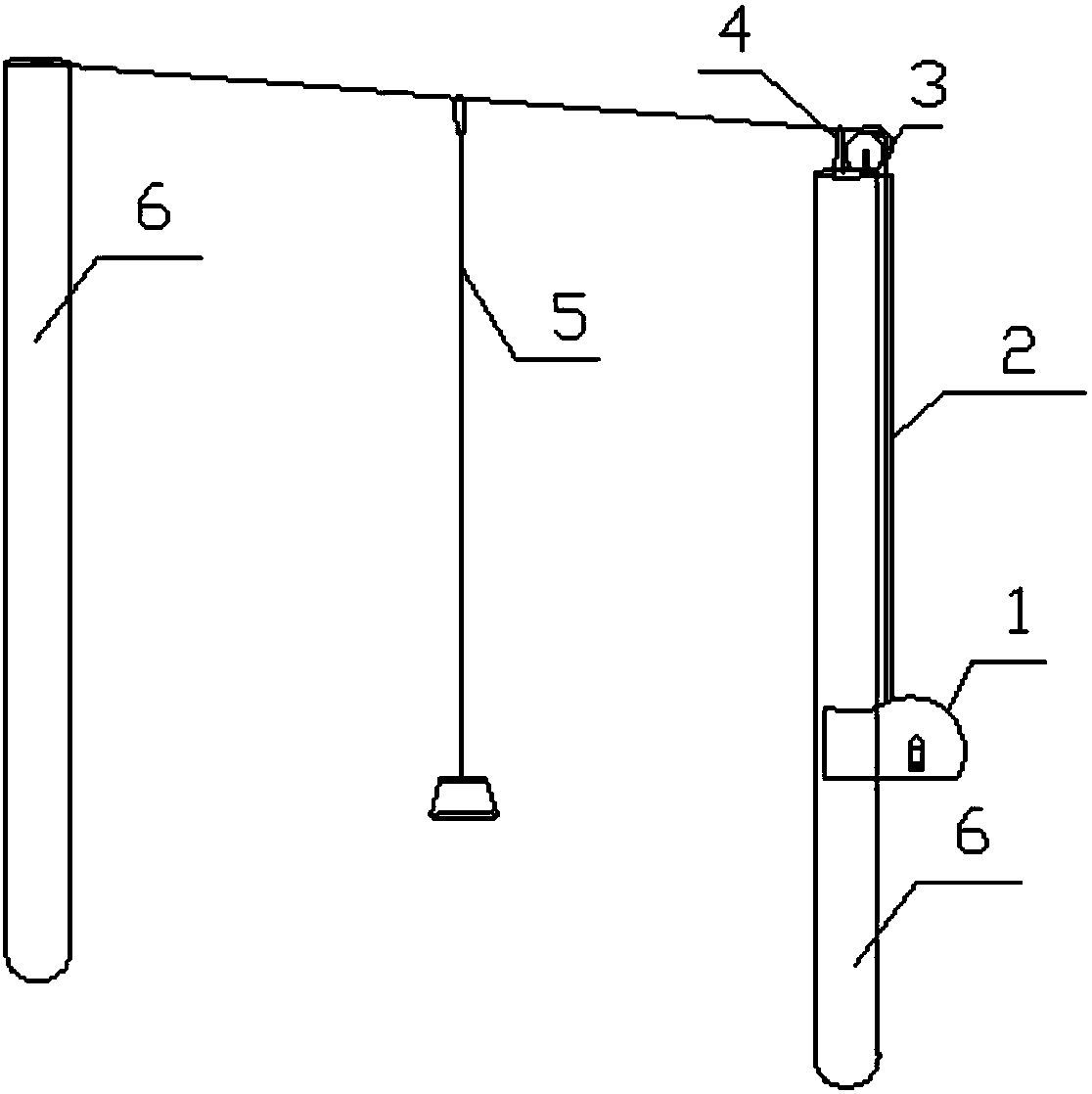

[0014] Example: such as figure 1 As shown, the present invention provides a ceiling pay-off device, which includes an ink fountain 1 with a built-in coil, a middle rotating shaft is arranged in the middle of the coil, one end of the middle rotating shaft is provided with an external rotating handle, and one end of the coil wire passes through a flexible cord The tube 2, the pulley 3, the crimping ring 4, the galvanized ring on the elastic cord 5, the top groove of the second operating rod rod and the center of the top of the second operating rod rod. The flexible cord tube 2 is Transparent plastic tube, the pulley 3 is made of hard wood, the pressing ring 4 is made of galvanized round steel, the main line of the elastic cord 5 is made of elastic rubber material, and the operating rod 6 is made of hard round wood.

[0015] The ink fountain 1 uses a 1mm thick plastic shell, the overall shape is a round cake, close to the side of the rod and the bottom side are flat, close to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com