Frame type low-position draining system tunnel lining structure

A drainage system, frame type technology, applied in the direction of tunnel lining, tunnel, drainage, etc., can solve the problems of uplift of the inverted arch, damage to the track bed structure, water accumulation on the track bed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments.

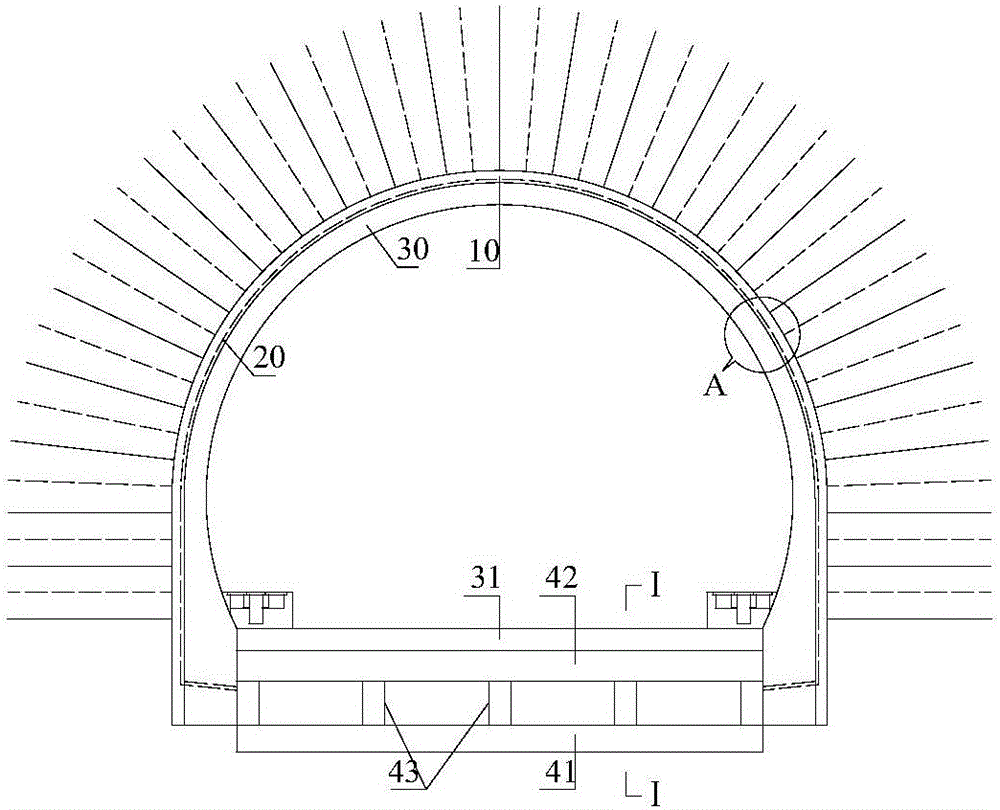

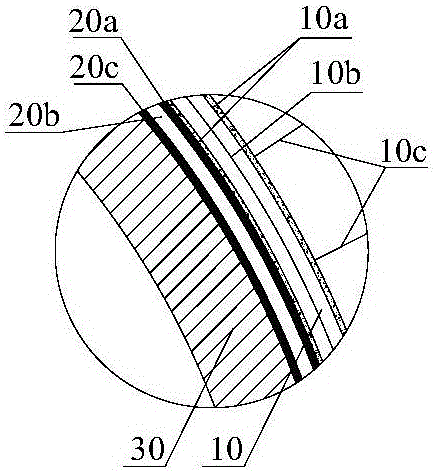

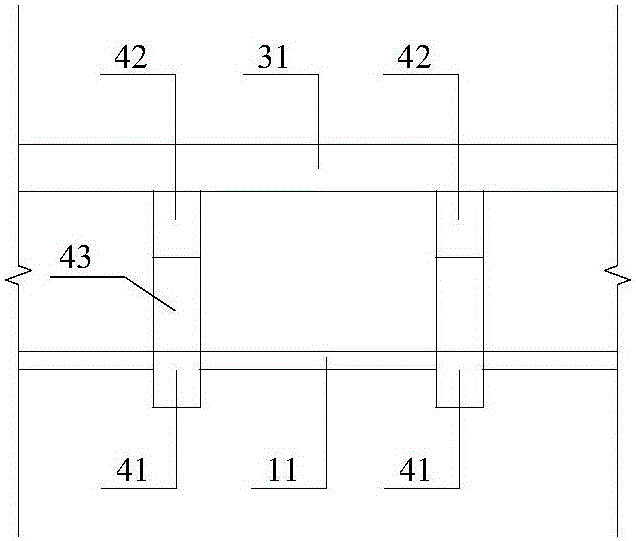

[0018] Reference figure 1 The frame-type low drainage system tunnel lining structure of the present invention includes the arch wall initial support structure 10, the arch wall secondary lining structure 30 and the bottom plate 31, and the arch wall initial support structure. Waterproof and drainage system 30 between 10 and the secondary lining structure 30 of the arch wall. Under the bottom plate 31, a tunnel bottom frame structure composed of a foundation beam 41, a short column 43 and a cross beam 42 is arranged as the bottom lateral bearing structure of the arch wall secondary lining structure 30 and the vertical bearing structure of the bottom plate 31. The lower end of the drainage system 20 leads to the tunnel longitudinal drainage channel arranged in the inner space of the tunnel bottom frame structure. . The frame-type tunnel bottom structure is used to rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com