Pipeline welding structure and air conditioner

A welding structure and pipeline technology, applied in the direction of non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of pipeline structure and design structure deviation, affect installation and stress distribution, etc., to ensure Assembly effect, effect of improving stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details. In other instances, well-known methods, procedures, components and circuits have not been described in detail so as not to obscure the present invention.

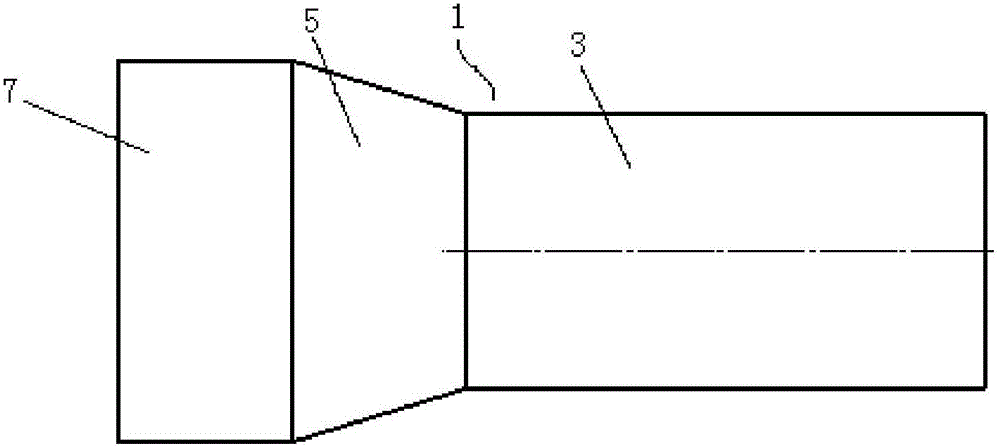

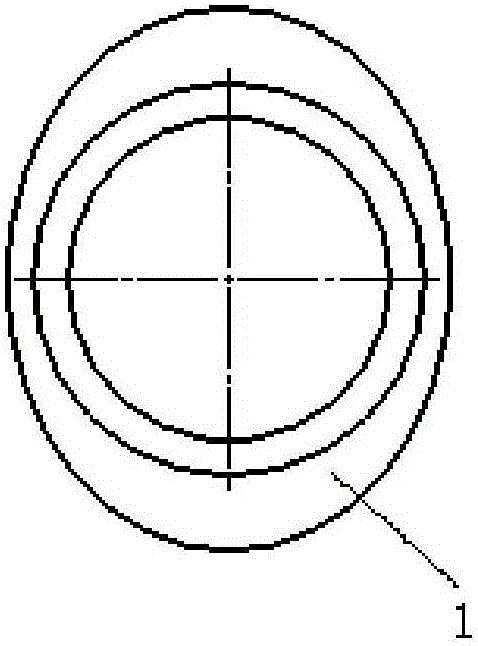

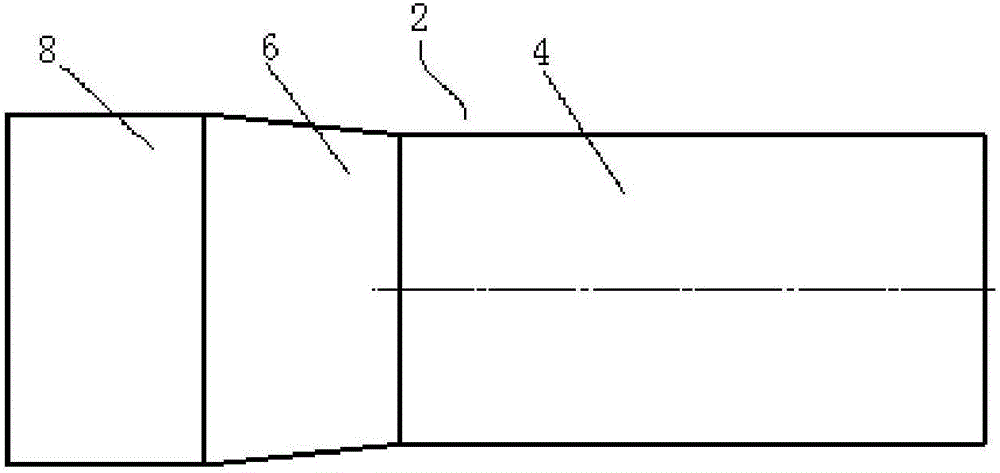

[0024] At present, the welding of the four-way valve and the pipeline of the four-way valve often has the problem of pipeline rotation, which leads to a large deviation between the pipeline structure after welding and the design structure, which affects the later installation and stress distribution.

[0025] The general way to solve this problem is to clamp and manually modify the pipeline structure. Clamping will reduce work efficiency. Manually correcting the pipeline structure not only reduces work efficiency but also makes it diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com