Iridium-based multi-component nano-porous catalyst as well as preparation method and application thereof

A multi-component composite and nanoporous technology, applied in nanotechnology, electrolytic components, electrolytic process, etc., can solve the problems of low anode electrolysis efficiency, large amount of precious metals used in the catalyst, and high cost, and achieve multiple surface active sites and low overpotential , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

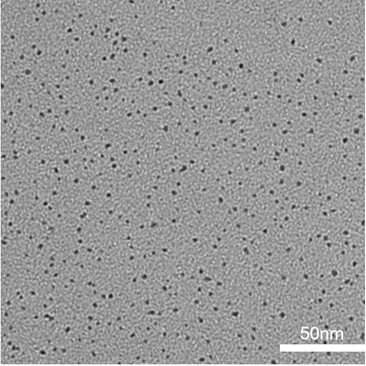

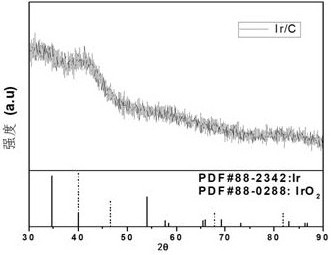

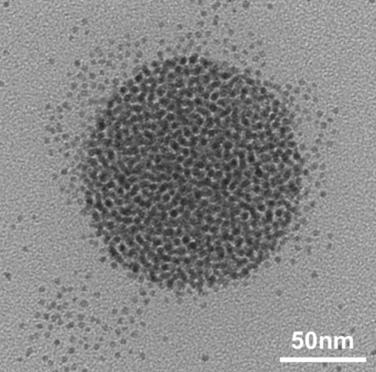

[0061] The present invention provides a method for preparing a iridium-based multi-composite nanoporous catalyst, comprising the following steps:

[0062] 1) Weigh iridium acetylacetonate (Ir(acac)) 3 ), mixed with 10 ~ 15 ml of oleylamine ultrasound, ultrasonic frequency of 20 ~ 40KHz, ultrasound time of 5 ~ 10 minutes, to obtain liquid 1, liquid 1 in Ir (acac) 3 The content is 4 to 7mg / ml; called methane tert-butylamine complex (BTB), mixed with 2 ~ 4ml of oleylamine, to give liquid 2, liquid 2 BTB content of 50 ~ 100mg / ml. Ir(acac) 3 The mass ratio of BTB is 1: (2 to 5). In a protective gas atmosphere, the liquid 1 is raised to 60 ° C ~ 90 ° C in a three-mouth flask, and the protective gas is nitrogen, argon or helium, and the temperature is maintained for 5 to 10 minutes to remove the low boiling point substance. Continue to heat the liquid 1 to 220 °C ~ 250 °C, after injecting liquid 2 into a three-mouth flask, continue to maintain a constant temperature of 0.5 ~ 1.5h at 22...

Embodiment 1

[0067] The present embodiment provides a method for preparing an iridium-based multi-component composite nanoporous catalyst, comprising the following steps:

[0068] (01) Dissolve 70mg of acetylacetone iridium in 10ml of oleylamine, sonicate evenly disperse, ultrasonic frequency 40kHz, ultrasound time 5 min, to obtain a light yellow solution.

[0069] (02) Weigh 200mg of methylborane tert-butylamine complex (BTB) dissolved in 4ml of oleylamine, ultrasonically dispersed uniformly to obtain a colorless solution.

[0070] (03) In a nitrogen atmosphere, transfer the light yellow solution of step (01) to a three-mouth flask, heat up to 60 °C, vacuum for 10 min to remove the low boiling point substance, and then heat up to 240 °C.

[0071] (04) After heating up to 240 °C in step (03), the colorless solution of step (02) is quickly injected into a three-mouth flask with a syringe and maintained at 240 °C for 1 h. In addition to evacuation, the gas atmosphere is nitrogen, and the gas vel...

Embodiment 2

[0080] The present embodiment provides a method for preparing an iridium-based multi-component composite nanoporous catalyst, comprising the following steps:

[0081] (01) Dissolve 60mg of acetylacetone iridium in 12ml of oleylamine, ultrasonically disperse evenly, ultrasonic frequency 30kHz, ultrasound time 8 min, to obtain a light yellow solution.

[0082] (02) Weigh 225mg of meborane tert-butylamine complex (BTB) dissolved in 3ml of oleylamine, ultrasonically dispersed uniformly to obtain a colorless solution.

[0083] (03) In a nitrogen atmosphere, transfer the light yellow solution of step (01) to a three-mouth flask, heat up to 80 °C, vacuum for 8 min to remove the low boiling point substance, and then heat up to 230 °C.

[0084] (04) After heating up to 230 °C in step (03), the colorless solution of step (02) is quickly injected into a three-mouth flask with a syringe and maintained at 230 °C for 0.5 h. In addition to evacuation, the gas atmosphere is nitrogen, and the gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com