Masonry Bracket Unit

A bracket device and masonry technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of large heat loss in the furnace, easy deformation, and cracks in the masonry, and achieve slow heat transfer speed and heat. The effect of slow transfer and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

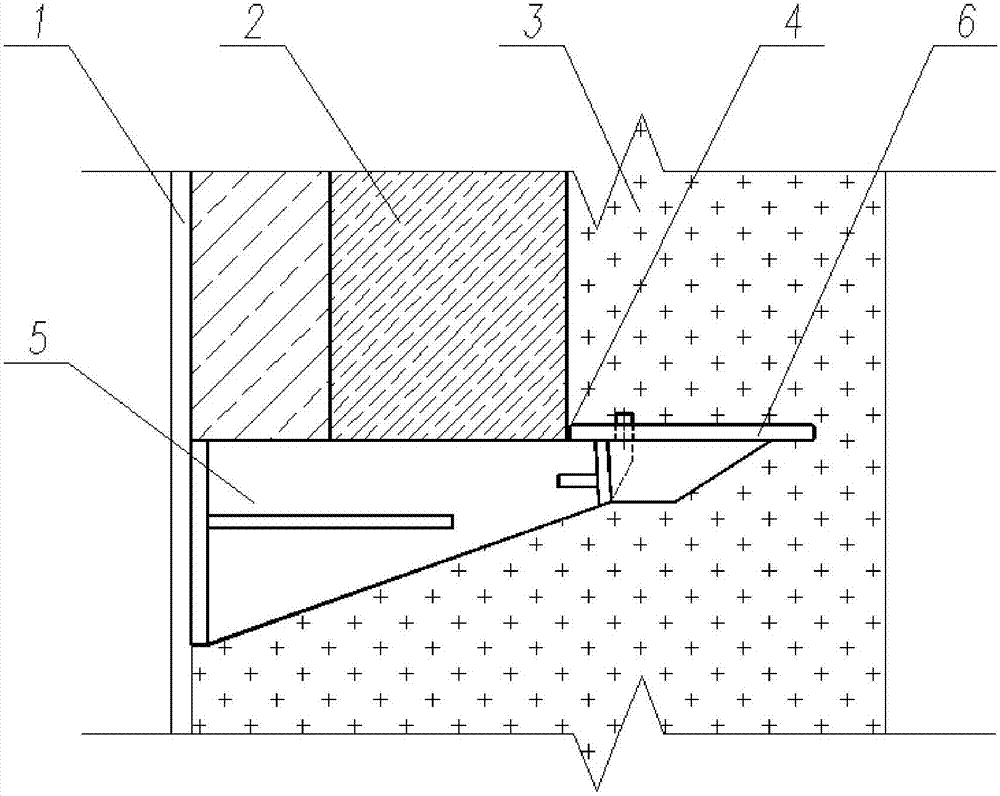

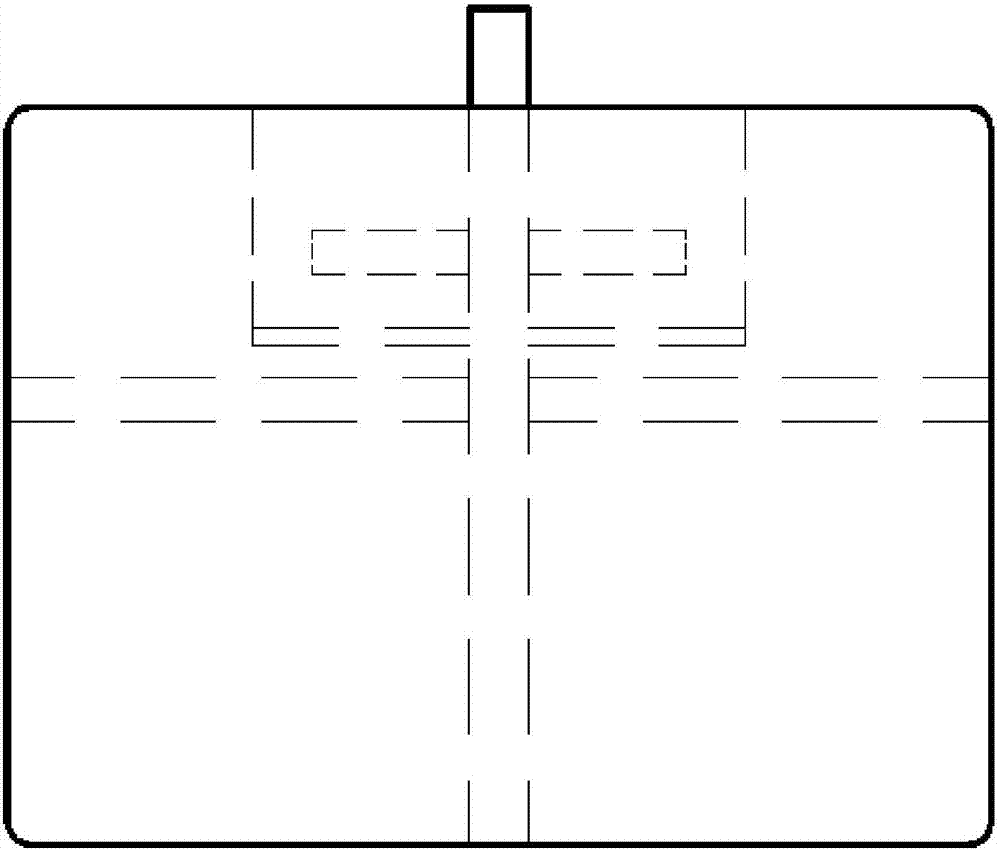

[0023] Such as Figure 1-6 As shown, the masonry bracket device of this embodiment includes a bracket 5 and a tray 6; wherein, the bracket 5 includes front and rear vertical plates arranged in parallel and at intervals, and two ends are connected with the front and rear vertical plates respectively. The connected connecting plate, the front of the front vertical plate is provided with a cylindrical boss 8; the tray 6 includes a horizontal supporting plate 4, a vertical stiffener 10 vertically arranged with the horizontal supporting plate 4, and a The circular hole 9;

[0024] When the boss is inserted into the circular hole 9, the rear side of the vertical stiffener 10 is attached to the front side of the front end plate.

[0025] The rear vertical plate and the masonry steel plate 1 are welded together, and the refractory brick 2 is built between the horizontal supporting plate 4 and the masonry steel plate 1, and the bracket 5, the tray 6 and the refractory brick 2 are cast...

Embodiment 2

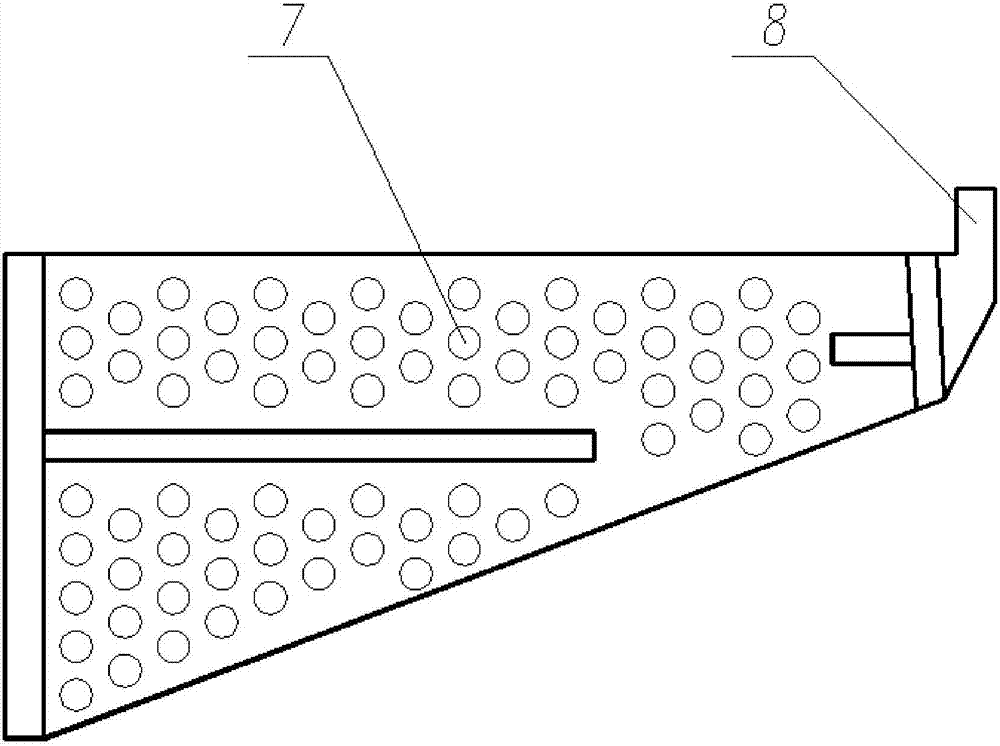

[0029] On the basis of the above embodiment, the vertical length of the front vertical board is smaller than the vertical length of the rear vertical board, the connecting board is arranged in the vertical plane, and the connecting board The shape is trapezoidal.

[0030] Since in the stress system of this embodiment, whether the moment change or the shear force change along the horizontal direction on the connecting plate decreases gradually from the rear side to the front side, the shape of the connecting plate is set in this embodiment It is trapezoidal, and the vertical length of the front vertical board is smaller than the vertical length of the rear vertical board. This design not only ensures the strength of the masonry bracket of this embodiment, but also saves materials and reduces the weight of the masonry bracket.

Embodiment 3

[0032] On the basis of the above-mentioned embodiment, a bracket stiffening plate is arranged between the front and rear vertical plates and the connecting plate, and the bracket 5 stiffening plate is perpendicular to the front and rear vertical plates and the The connecting plate, the stiffening plate of the bracket 5 is a triangular plate.

[0033] A stiffening plate is arranged between the front and rear vertical plates and the connecting plate, which can enhance the rigidity of the bracket 5 to both sides, and when the bracket is subjected to forces on the left and right sides, no plastic deformation will occur, avoiding the impact caused by the casting material. 3 extrusion and deformation. If the bracket is deformed, the support capacity for the heat-resistant bricks and castables above will be reduced, so it is necessary to avoid plastic deformation of the bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com