Shock wave pressure testing structure used in explosion near field

A pressure test and shock wave technology, applied in the field of explosion testing, can solve the problems of large vibration parasitic output, affecting the calculation of shock wave impulse value, and shock wave signal deformation, so as to reduce the impact and achieve the effect of accurate testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

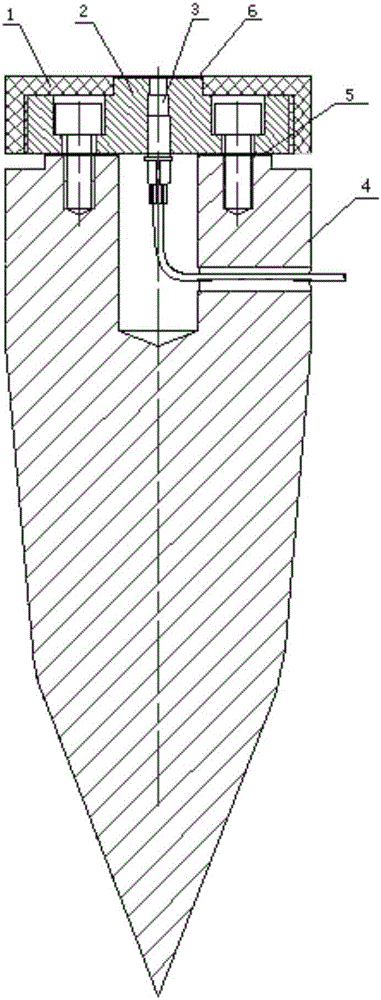

Method used

Image

Examples

Embodiment 1

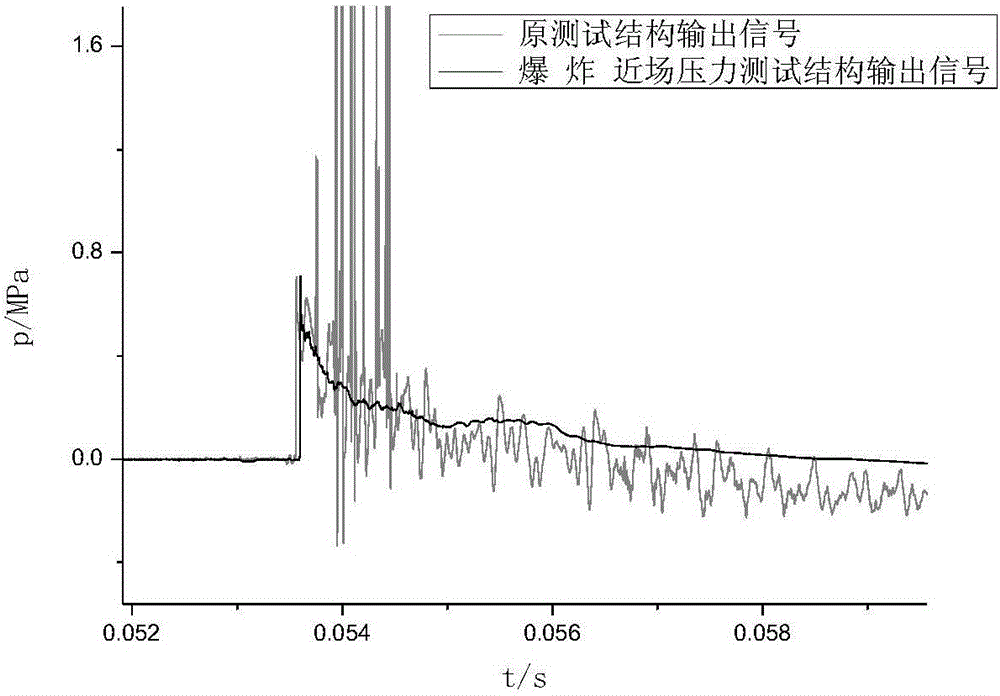

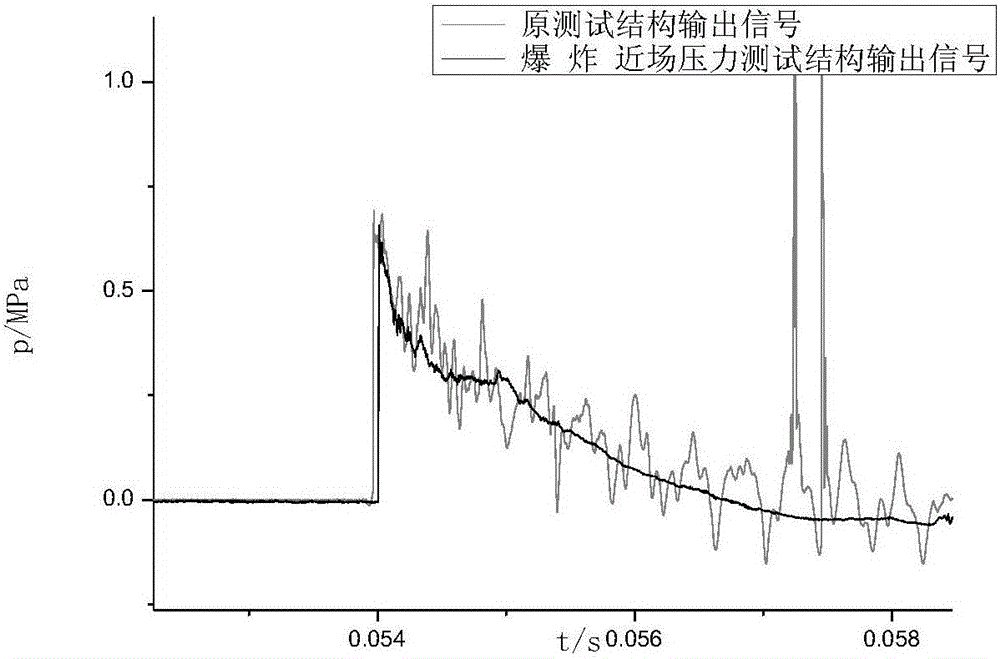

[0028] Use the PCB 113 pressure sensor as the test sensor, install it on the test structure, and place it at a position where the contrast distance from the blast center is 1. The shock wave pressure signal obtained is as follows: figure 2 Shown by the black solid line. image 3 In are the shock wave pressure signals obtained from the explosion of different ammunition. figure 2 and image 3 The middle gray solid line is the pressure signal obtained with the original test structure.

[0029] It can be seen that due to the impact of strong vibration on the original test structure, the shock wave signal is superimposed on the parasitic output of the pressure sensor caused by the vibration, and the ratio of the shock wave measurement deviation caused by the vibration to the peak value of the shock wave reaches a maximum of 30%. There are even superimposed signals that the rear circuit of the pressure sensor is suddenly disconnected or the signal line connector is vibrated and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com