Dielectric test system and method for micro-nano graphical film array

A dielectric testing and graphic technology, applied in the direction of dielectric performance measurement, measuring electricity, measuring devices, etc., can solve the problems of increased testing cost, expensive equipment, high testing cost, etc., and achieve high hardness, heat resistance and low temperature resistance, Avoid loss and noise, quickly test the effect of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

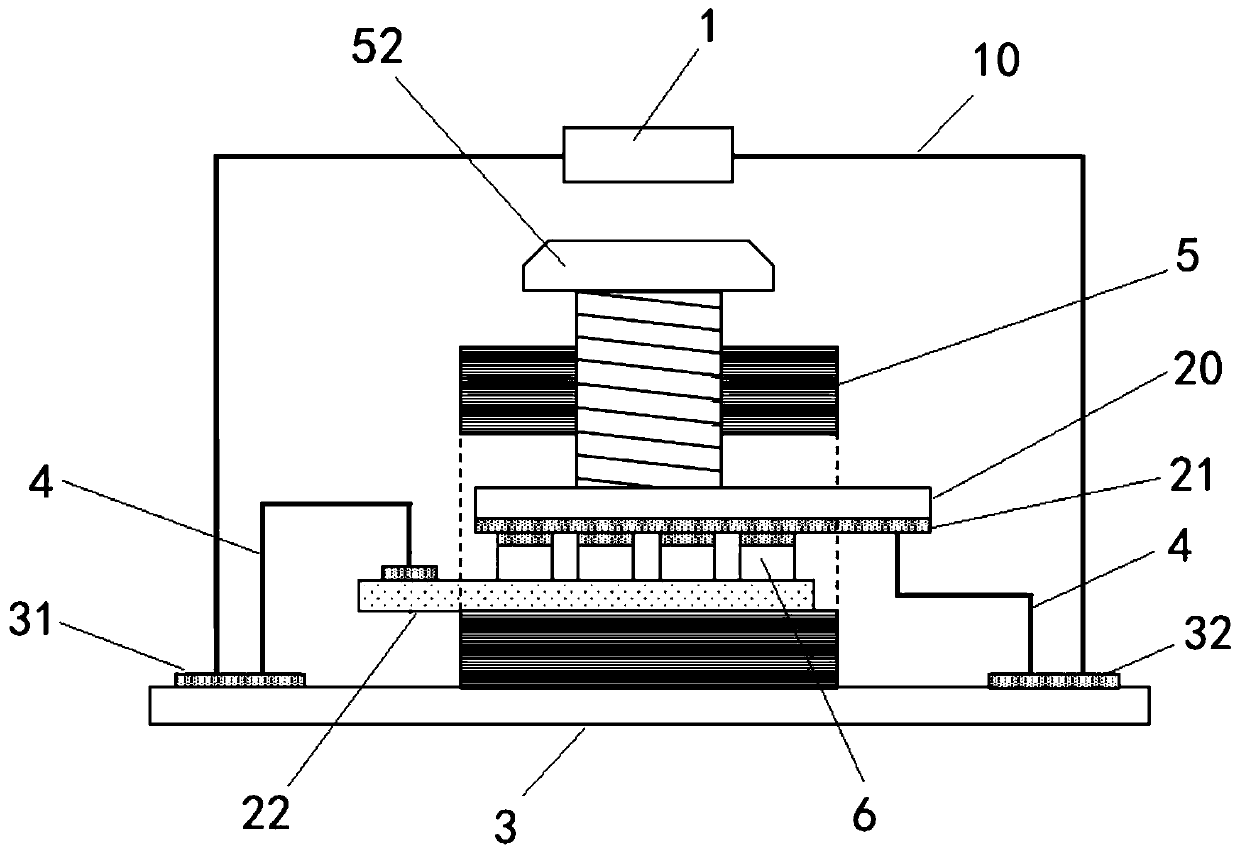

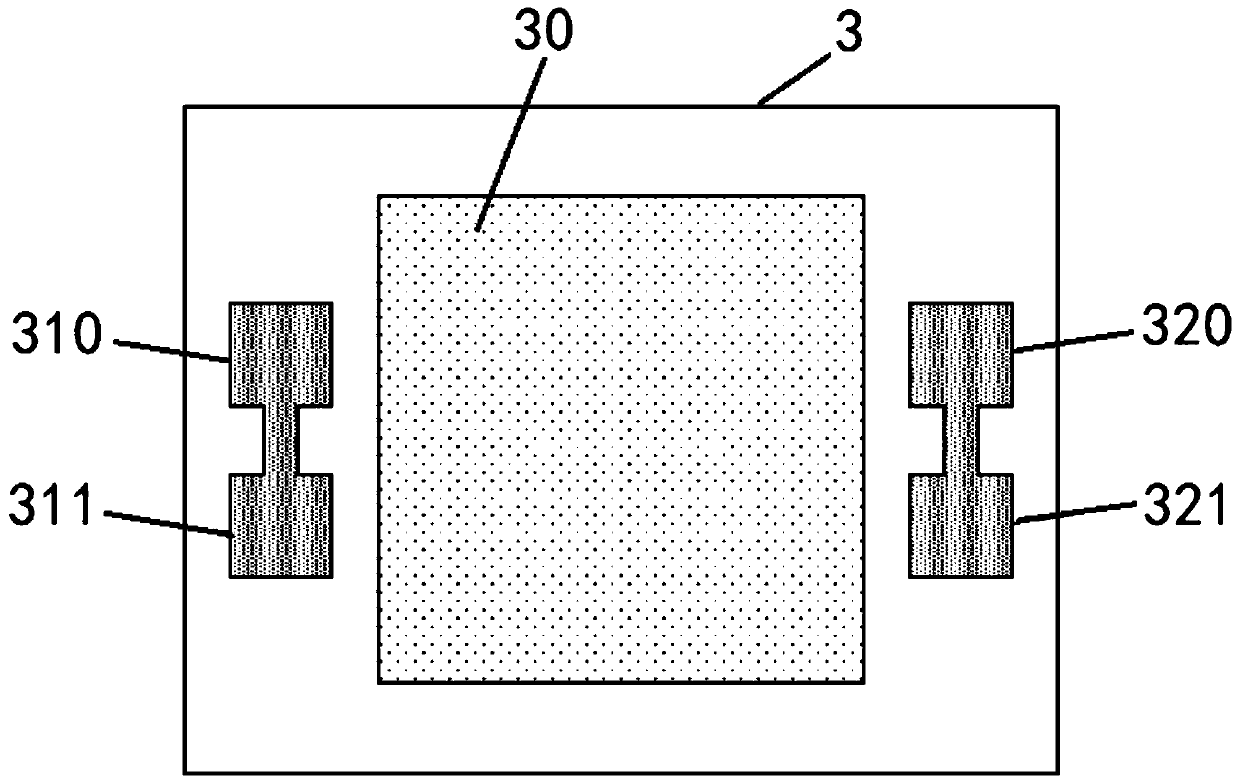

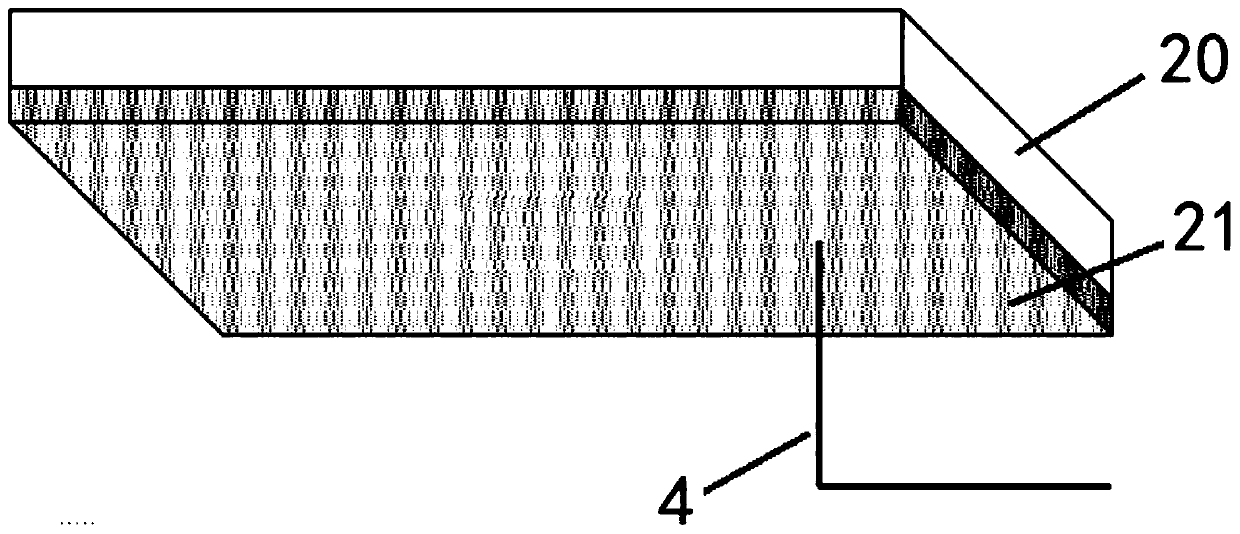

[0053] see figure 1 , a dielectric testing system for micro-nano-sized patterned film arrays according to a preferred embodiment of the present invention, comprising: a testing unit 1 for testing dielectric properties, an insulating sample stage 3, and a relatively parallel first An electrode 21, a second electrode 22 and an insulated test fixture 5 are used to sandwich a micro-nano-sized patterned film array 6 between the first electrode 21 and the second electrode 22, and the first electrode 21 and the second electrode 22 are respectively located Above and below the patterned thin film array 6 of micro-nano size.

[0054] According to the required test parameters, select the appropriate test instrument as the test unit 1.

[0055] In order to reduce the influence of the weak dielectric effect of the sample stage 3 itself on the test data, the present invention uses a highly insulating material (such as Al 2 o 3 ) as the sample stage 3, using a vacuum coating method (such ...

Embodiment 2

[0064] A method for testing the dielectric properties and / or magnetodielectric properties of a micro-nano-sized patterned film array is carried out by using the dielectric testing system of Embodiment 1 of the present invention, and the steps are as follows:

[0065] Place the first electrode 21 and the second electrode 22 sandwiched with the micro-nano-sized patterned film array 6 in the sample groove 50 of the test fixture 5, and then use the fastening unit 52 to pressurize the first electrode 21 so that the first electrode 21. The micro-nano-sized patterned film array 6 and the second electrode 22 are in close contact with each other; and the test fixture 5 is placed on the sample stage 3;

[0066] Two places of the first sample stage electrode 32 on the sample stage 3 are electrically connected with the first electrode 21 and one end of the test unit 1 respectively, and two places of the second sample stage electrode 31 on the sample stage 3 are connected with the second el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com