Disc type passenger train brake tube box

A tube box and passenger car technology, which is applied to vehicle testing, measuring devices, instruments, etc., can solve the problems of increased flow resistance, limited space, and inconvenience in arbitrary grouping, and achieves the effect of convenient use, simple structure, and convenient grouping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

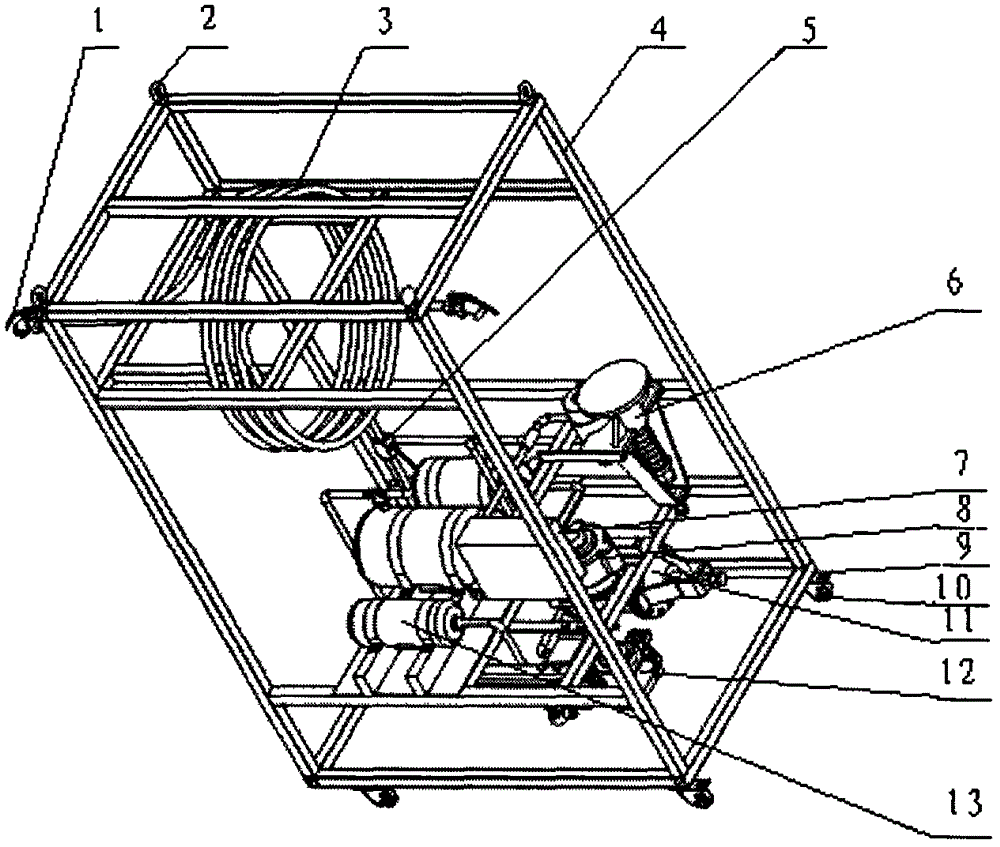

[0009] As shown in the attached picture.

[0010] The specific implementation method is: take the brake tube box 4 as the installation basis, first install 4 tube box suspension rings 2, 4 castors 10 and 4 pedals 9, then install the brake cylinder 11 and the 120 type distribution valve 12, then Install the proportional valve 8 for empty and heavy trucks and the valve 6 for empty and heavy trucks, then install the 11L acceleration relief air cylinder 13 and the fixed circuit box 7 of ECP120, install the angled plug door 5 of the branch pipe and connect the train pipe coil 3 while adjusting it, and finally install 4 ferrules type pipe joints.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com