Multi-port valve

A multi-channel and valve technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of energy saving and consumption reduction, affecting production efficiency, increasing production costs, etc., to achieve cost saving, convenient use and maintenance. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

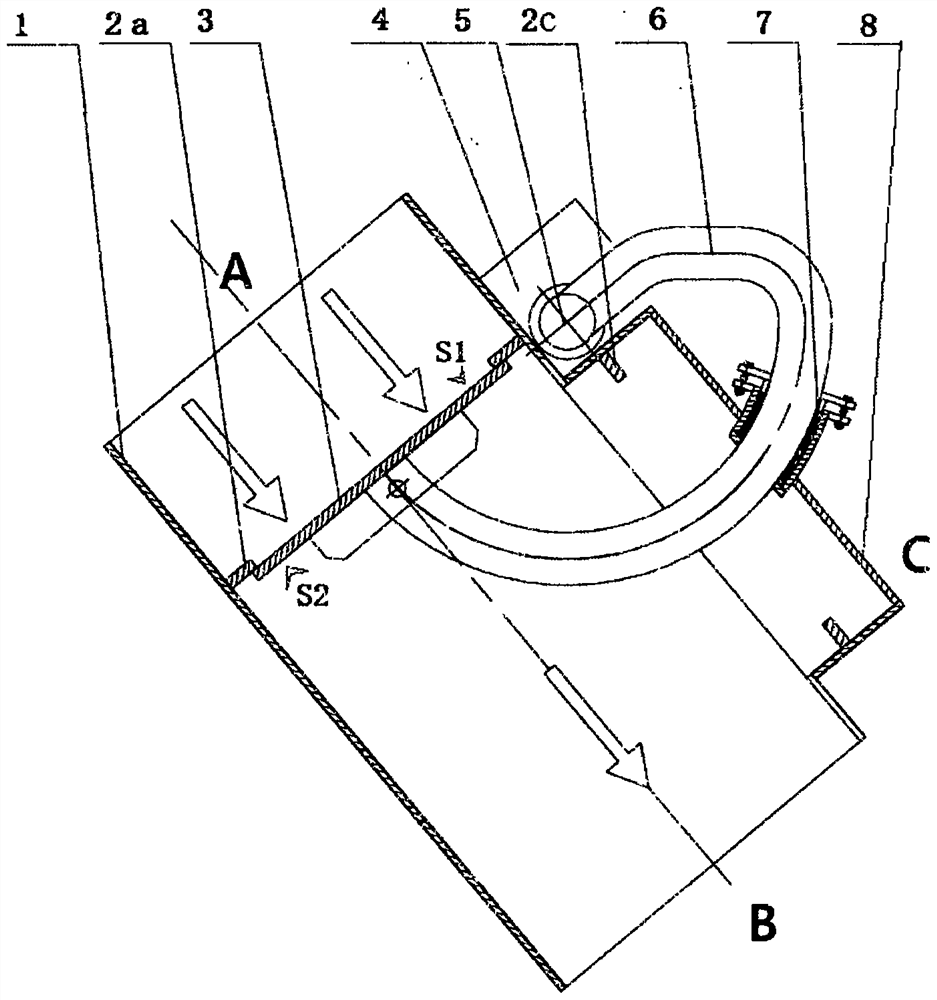

[0035] A three-way valve, such as figure 1As shown, it includes a valve body 1, a valve plate 3, a driving structure 4, a main shaft 5 and a crank 6; the valve body 1 has three medium flow ports A, B, and C, and the A port and the B port are coaxial and the A port is opposite to each other. Port B is located upstream of the flow direction of the medium, port C is not coaxial with ports A and B, and is open sideways to the axis of ports A and B; the inner walls of port A and port C are respectively provided with valve seats 2a and 2c, and the valve seats are located The medium flows to the downstream, while the C port and its valve seat 2c are located above the axis of the A and B ports; the valve plate 3 is set in the valve body 1, and has two sealing surfaces S1 and S2 to serve as the corresponding valve The sealing surface S1 and S2 are respectively located on the two axial end surfaces of the valve plate 3; the main shaft 5 is located outside the valve body 1, and the crank...

Embodiment 2

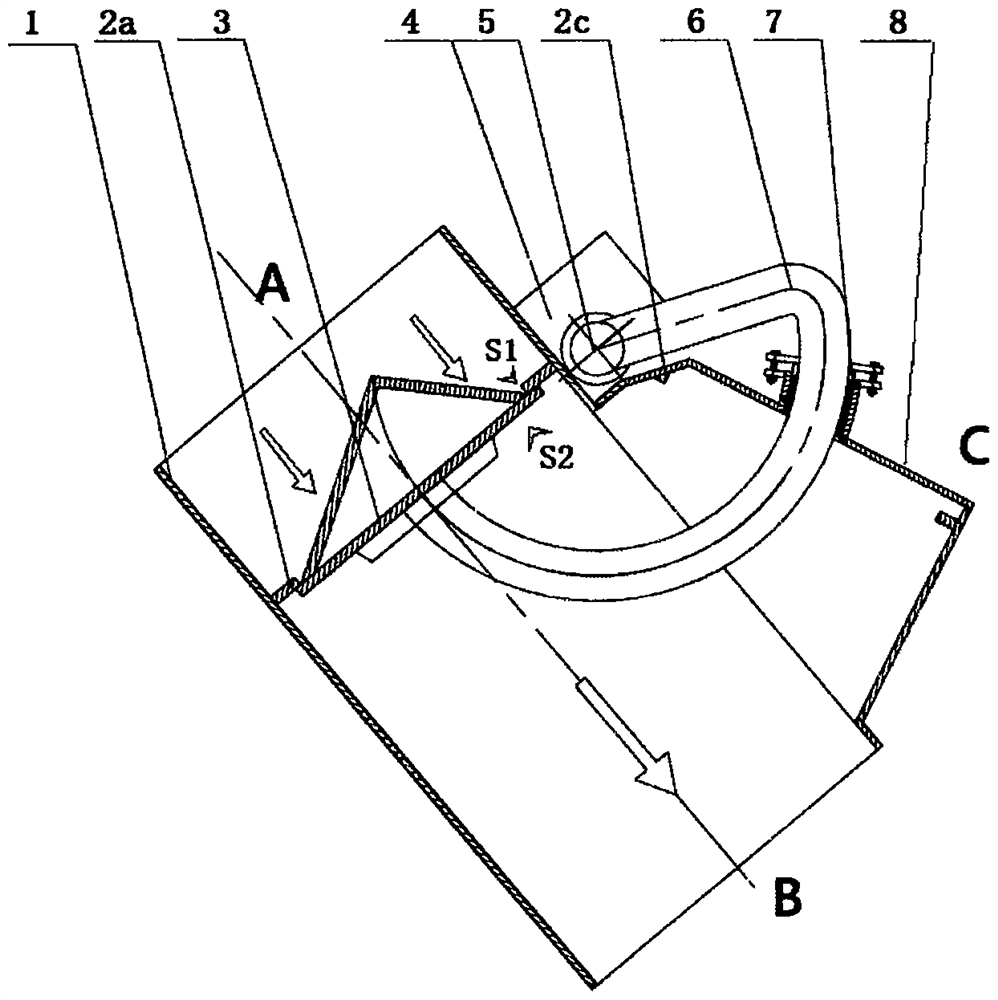

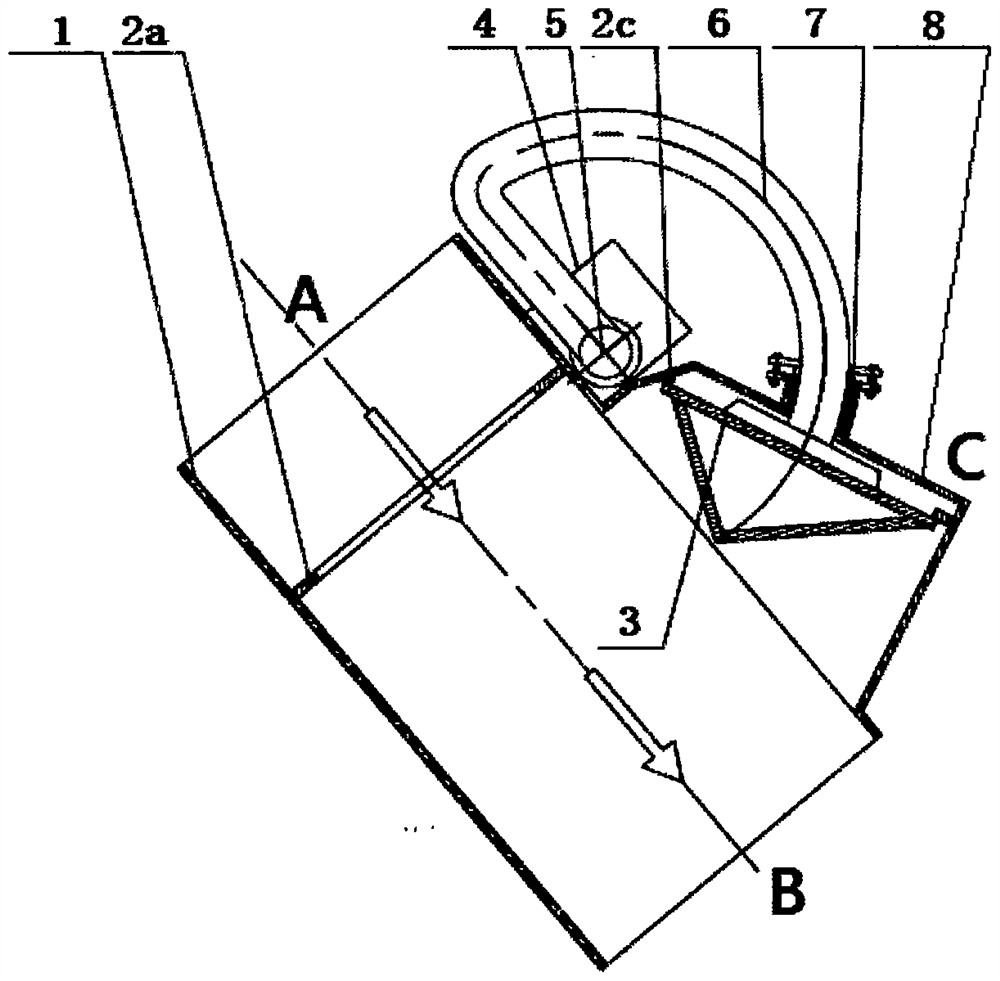

[0037] A three-way valve, such as figure 2 and image 3 Shown; Same as Embodiment 1, it has 3 media flow ports A, B, C, including valve body 1, valve plate 3, drive structure 4, main shaft 5, crank 6 and crank packing box 7, etc.; The main shaft is set outside the valve body 1, and the crank 6 adopts a fan-like ring structure and passes through the crank packing box 7 on the inspection hole cover 8 of the port C to penetrate inside and outside the valve body 1 and drive The valve plate 3 rotates, that is, the valve plate 3 rotates around the main shaft 5 to realize the position change between the valve seat 2a of the A port and the valve seat 2c of the C port, and through its two axial end faces Two opposite sealing surfaces S1, S2 are respectively connected with the valve seat 2a of port A (such as figure 2 shown) and the valve seat 2c of port C (such as image 3 shown) fit and seal to realize its two-position three-way function;

[0038] The difference from Embodiment ...

Embodiment 3

[0040] A three-way valve, such as Figure 4 and Figure 5 As shown, its overall structure is basically the same as that of Embodiment 1, including a valve body 1, a valve plate 3, a main shaft 5, a fan-like annular crank 6, and a crank packing box 7; the main shaft 5 is arranged outside the valve body 1 , the valve plate 3 has two sealing surfaces S1, S2 which are respectively located on the two axial end surfaces of the valve plate 3, and the valve body has three media flow ports A, B, C. The function realization of its two-position three-way is also identical with embodiment 1.

[0041] The difference is that in the valve described in this embodiment, the inner wall of the valve body 1 and the axial end surface where the sealing surface S1 of the valve plate 3 is located are all covered with a thermal insulation lining 10 and a wear-resistant lining 9 in sequence, that is, on the The inner wall of the valve and the axial end surface of the valve plate are covered with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com