A device for improving on-site X-ray shooting efficiency of gas-insulated switch

A gas insulated switch and X-ray technology, applied in measuring devices, material analysis using radiation, material analysis using wave/particle radiation, etc., to achieve the effect of improving shooting efficiency, shortening inspection time, and improving time economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

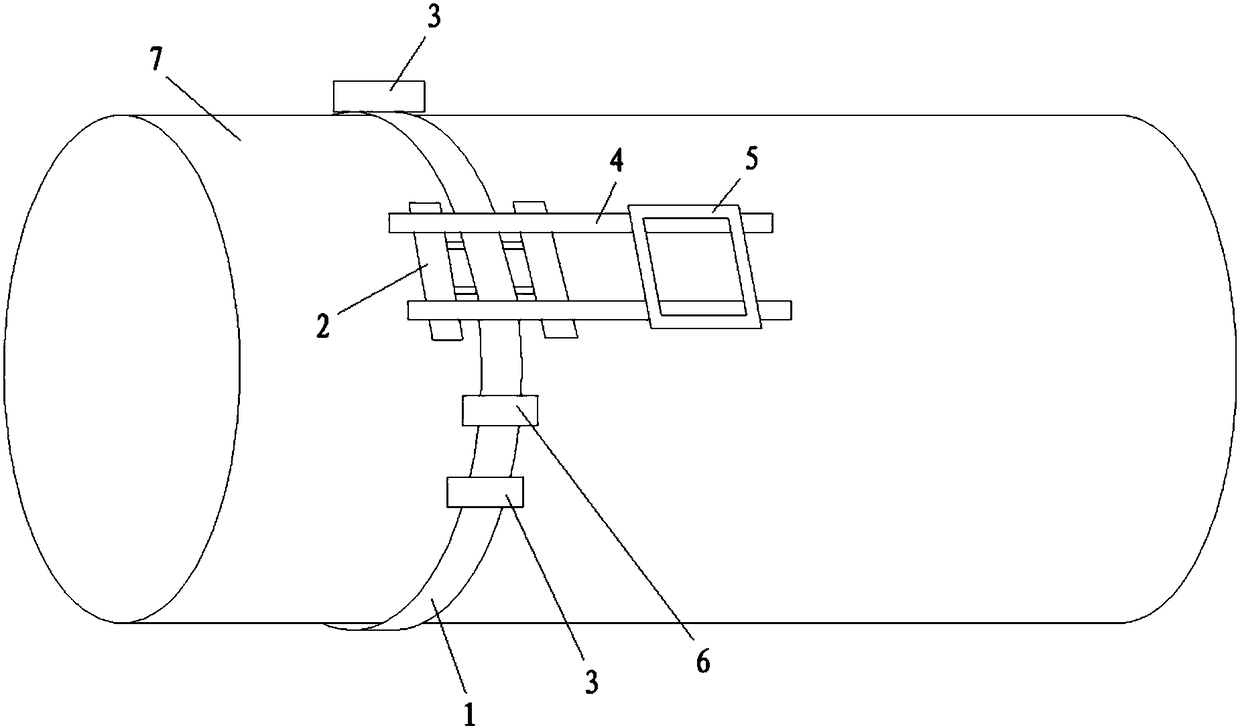

[0024] Such as figure 1 As shown, a device for improving the on-site X-ray shooting efficiency of a gas insulated switch includes: a nylon belt 1, a main bracket 2, a bridge bracket 3, a sliding guide rail 4, an imaging plate fixing frame cover 5, and a fastener 6; , the nylon belt 1 passes through a plurality of bridge brackets 3 and main brackets 2 in turn, and after the two ends of the nylon belt 1 are connected with hooks, they are placed on the surface of the bus barrel body 7; The surface of the bus barrel body 7 rolls, thereby determining the position of the imaging plate fixing frame cover 5 on the main bracket 2; meanwhile, the imaging plate fixing frame cover 5 can also move laterally on the sliding guide rail 4, thereby realizing the alignment of the bus bar barrel body 7 comprehensive inspection.

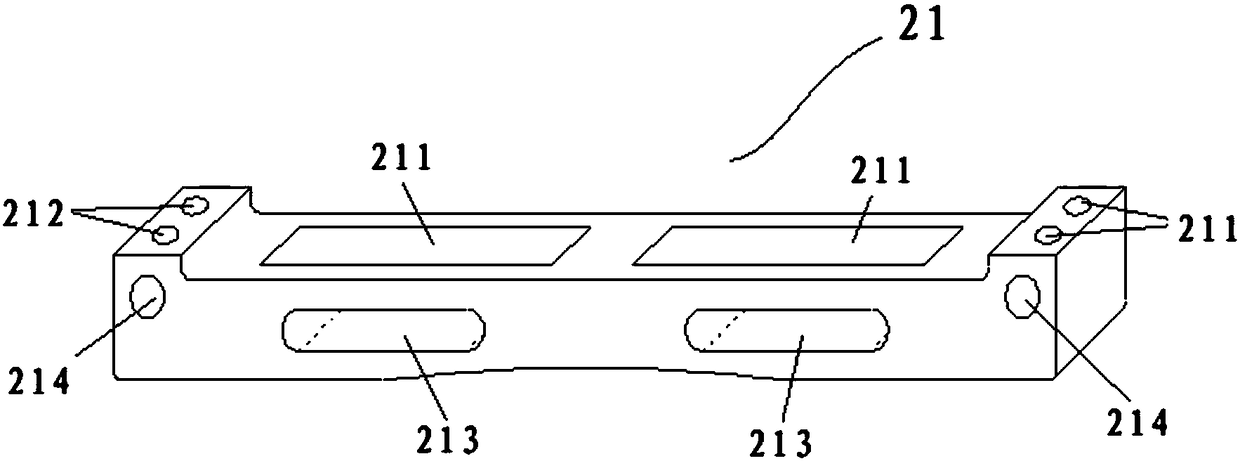

[0025] Such as figure 2 , image 3 As shown, the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com