Efficiency calculation method for novel SCR (Selective Catalytic Reduction) denitration device

A technology for efficiency calculation and denitrification efficiency, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the flue gas flow rate that is not considered, and achieve accurate and scientific concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes the embodiments of the present invention in further detail: It should be emphasized that the embodiments described in the present invention are illustrative rather than restrictive. Therefore, the present invention is not limited to the embodiments described in the specific implementations. Other implementation manners obtained by those skilled in the art according to the technical solution of the present invention also fall within the protection scope of the present invention.

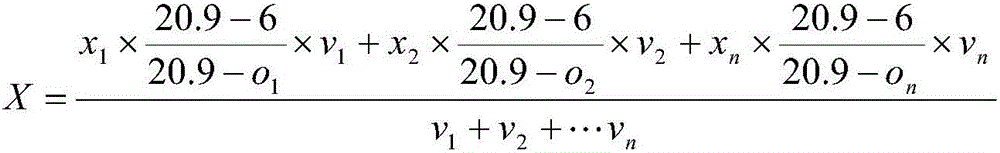

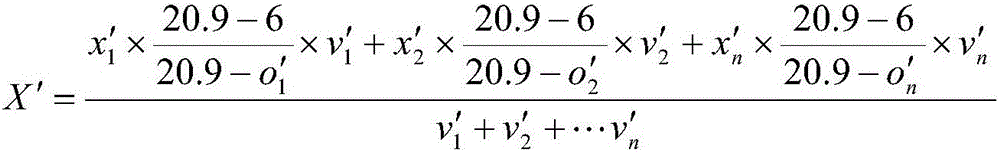

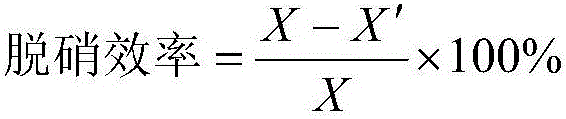

[0025] A method for calculating the efficiency of a new SCR denitrification unit, which includes:

[0026] (1) According to the method in 4.2 of GB / T 16157-1996 "Determination of Particulate Matter in Exhaust from Stationary Pollution Sources and Sampling Method of Gaseous Pollutants", select and sample sampling points;

[0027] (2) Perform sampling measurement of flue gas flow rate, oxygen content and nitrogen oxide content at each sampling point of the inlet and outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com