Matching method for mixture mix ratio at regenerative microcapsule position based on torsional shear test

A technology of micro-surface mixing and mixing ratio, which is applied in data processing applications, instruments, roads, etc., to achieve the effect of excellent road performance and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

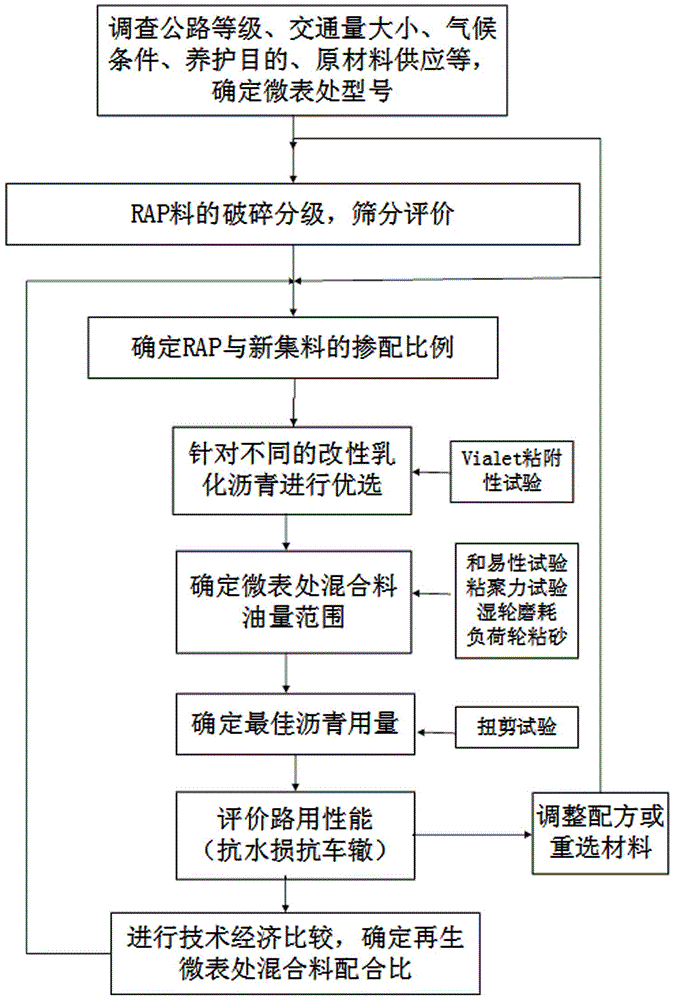

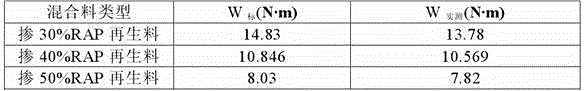

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will now be further described in conjunction with the embodiments and accompanying drawings, but the present invention is not limited to the following embodiments.

[0029] 1. The gradation type selected in this embodiment is MS-Ⅲ, and its maximum particle size is 9.5 mm. Use a 9.5 mm standard sieve to screen out super-sized particles.

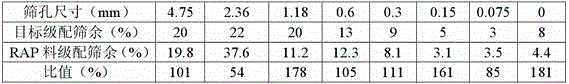

[0030] 2. Determine the gradation of RAP material ore through the combustion furnace method and sieving test, as shown in Table 1:

[0031] Table 1 Gradation of RAP material ore

[0032]

[0033] The bitumen content of the RAP material is 4.3%.

[0034] 3. Target grading is shown in Table 2.

[0035] Table 2 MS-Ⅲ target gradation

[0036]

[0037] The target gradation and RAP material gradation are shown in Table 3 below for the sieve residue and the corresponding sieve hole ratio.

[0038] Table 3 Screening Summary Results Table

[0039]

[0040] The minimum ratio in Table 3 is 54%, and it is determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com