Asphalt cold mixing repairing composite material and preparation method thereof

A composite material and asphalt technology, applied in the field of asphalt cold mix repairing composite materials, can solve the problems of shortened service life, high temperature sensitivity, low pavement strength, etc., and achieves prevention of secondary damage, excellent road performance, and bonding performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

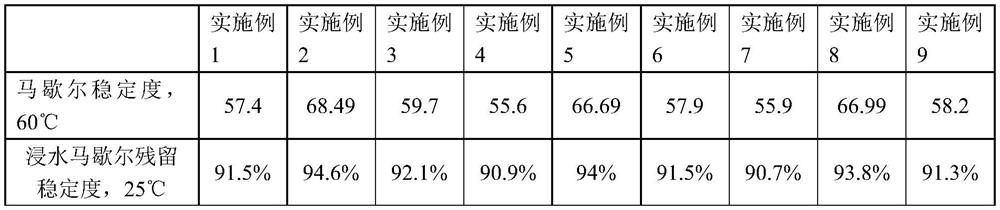

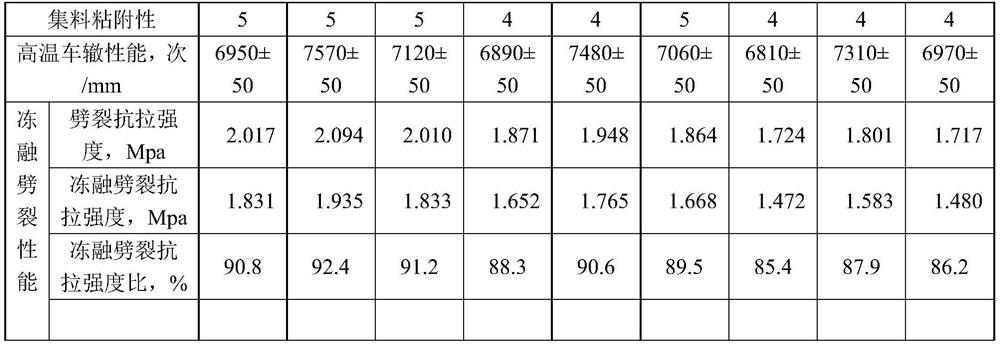

Embodiment 1

[0025] Asphalt cold-mix repair composite material, composed of part A and part B with a mass ratio of 6:100; part A includes 10 parts of siloxy-terminated polyether resin, 0.5 part of 3-glycidoxypropylmethyldiethyl Calcium carbonate modified by oxysilane, 100 parts of asphalt modified polysulfide rubber, 0.2 part of manganese dioxide, 10 parts of dibutyl phthalate, 15 parts of aromatic oil, 1.5 parts of composite catalyst, the composite catalyst is attached Silica of 12%wt organotin and 10wt% organotitanium; Part B is a mixed aggregate obtained by grinding limestone and andesite with a mass ratio of 2:1, and the mixed aggregate includes a particle size of 11-22mm Coarse aggregate, medium aggregate with a particle size of 6-11 mm and fine aggregate with a particle size of 0-6 mm; the mass ratio of the coarse aggregate, coarse aggregate and fine aggregate is 9:6:10.

[0026] The preparation method is as follows: (1) prepare bitumen-modified polysulfide rubber and calcium carbona...

Embodiment 2

[0028]The difference from Example 1 is that the asphalt cold-mix repair composite material is composed of part A and part B with a mass ratio of 4.5:100; and the proportion of part A is different, including 18 parts of silicone-terminated polyether resin, 6 parts 3-Glycidoxypropylmethyldiethoxysilane modified calcium carbonate, 100 parts of bitumen modified polysulfide rubber, 0.8 parts of manganese dioxide, 15 parts of dibutyl phthalate, 15 parts of aromatic hydrocarbon oil, 1.8 parts of composite catalyst; wherein, the bitumen-modified polysulfide rubber is prepared by the following method: heating base asphalt to 150-160°C, adding polysulfide rubber, keeping the temperature at 170-180°C, and dispersing at high speed for 30-40min, After cooling down, add γ-aminopropyl triethoxysilane, develop and stir at 150°C for 30 minutes, wherein, the amount of base asphalt added is 18wt% of the polysulfide rubber, and the γ-aminopropyl triethoxy The blending amount of base silane is 8wt...

Embodiment 3

[0030] The difference from Example 1 is that the asphalt cold-mix repair composite material is composed of part A and part B with a mass ratio of 7:100; and the proportion of part A is different, including 25 parts of siloxy polyether resin, 6 parts 3-Glycidoxypropylmethyldiethoxysilane modified calcium carbonate, 100 parts of bitumen modified polysulfide rubber, 0.6 parts of manganese dioxide, 15 parts of dibutyl phthalate, 12 parts of aromatic hydrocarbon oil, 2.1 parts of composite catalyst; wherein, the bitumen-modified polysulfide rubber is prepared by the following method: heating base asphalt to 150-160°C, adding polysulfide rubber, keeping the temperature at 170-180°C, and dispersing at high speed for 30-40min, After cooling down, add γ-aminopropyl triethoxysilane, and develop and stir at 150°C for 30 minutes to prepare, wherein, the blending amount of base asphalt is 10wt% of polysulfide rubber, and the γ-aminopropyl triethoxy The blending amount of base silane is 5wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| freeze-thaw splitting strength ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com