Improved structure of screen cloth of mud vibrating screen for marine drilling

A technology of offshore drilling and sieve screen, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problem of loss and departure of the recoverable liquid phase of drilling fluid, and achieve the effects of protecting the environment, avoiding damage, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

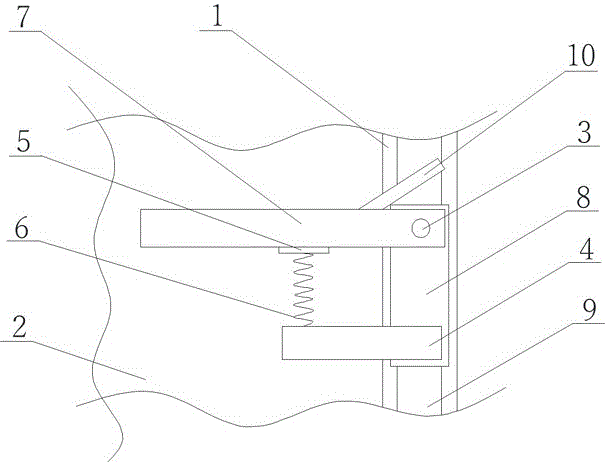

[0025] like figure 1 As shown, the present invention is an improved structure of a shale shaker screen used for offshore drilling, including a screen frame 1, a screen 2 is arranged in the screen frame 1, a guide rail 9 is arranged on the screen frame 1, and the guide rail 9 guides from the drilling The inlet of the drilling fluid extends to the outlet of the drilling fluid. A number of sliders 8 are arranged on the guide rail 9. A fixed baffle 4 is installed on the end of the slider 8 close to the outlet of the drilling fluid, and a movable baffle 7 is installed on the other end. The longer side of the contact surface between the baffle 4 and the slider 8 is perpendicular to the slider 8, the height of the fixed baffle 4 is parallel to the normal direction of the slider 8, the fixed baffle 4 is parallel to the movable baffle 7, and the fixed baffle 4 and the movable baffle 7 are provided with a spring 6, one end of the spring 6 is vertically fixed on the fixed baffle 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com