Sprue device of magnesium alloy front-end support pressure castings

A front-end bracket and magnesium alloy technology, which is applied in the field of gate devices, can solve the problems of reduced strength and small heat capacity of magnesium alloy materials, and achieve the effects of weight reduction, strength assurance, and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

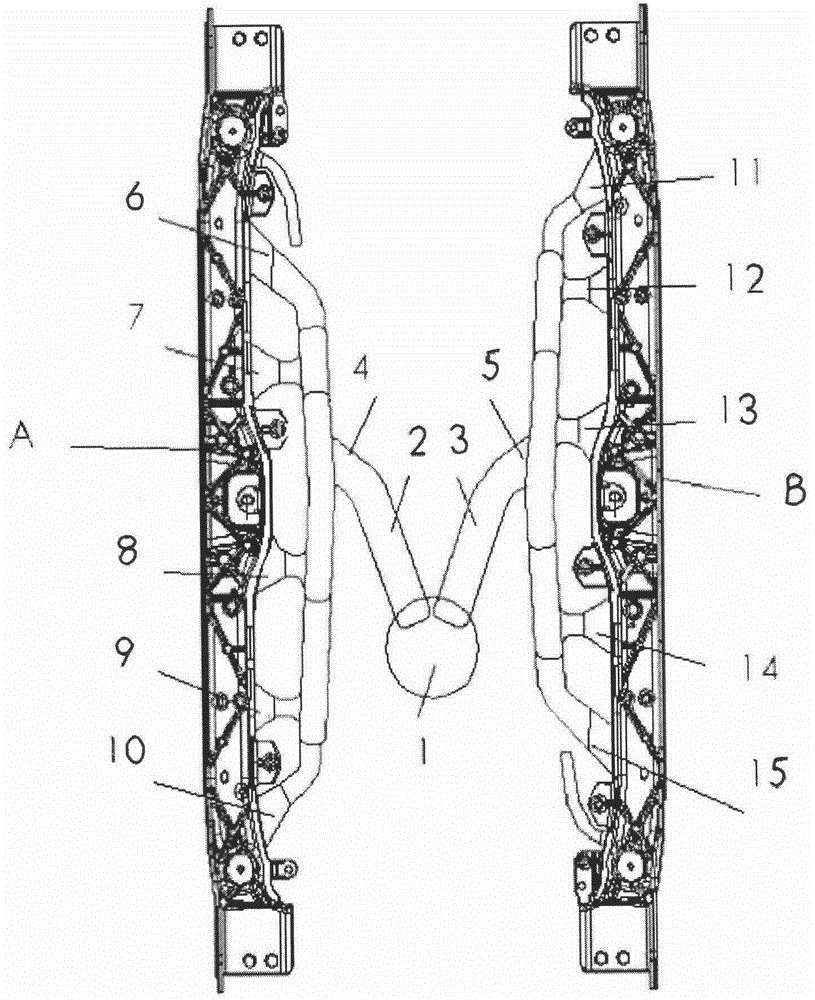

[0010] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0011] Depend on figure 1 It can be seen that the present invention includes: a pressure chamber 1; the pressure chamber 1 is divided into two channels; the shape of the two channels is "fan" type, passing through the first sprue 2, the first runner 4 and the second The two sprues 3 and the second runner 5 are connected with the first casting body A and the second casting body B; the first runner 4 divides into five ways and enters the first gate of the first casting body A respectively 6. The second gate 7, the third gate 8, the fourth gate 9 and the fifth gate 10; the second runner 5 is divided into five ways to enter the sixth gate of the second casting body B 11. The seventh gate 12, the eighth gate 13, the ninth gate 14 and the tenth gate 15;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com