Wheel suspension for travelling crane, and crane

A technology of mobile cranes and wheel suspensions, which is applied to construction cranes, suspensions, motor vehicles, etc., and can solve problems such as asymmetric steering errors and affecting the stability of vehicle driving directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

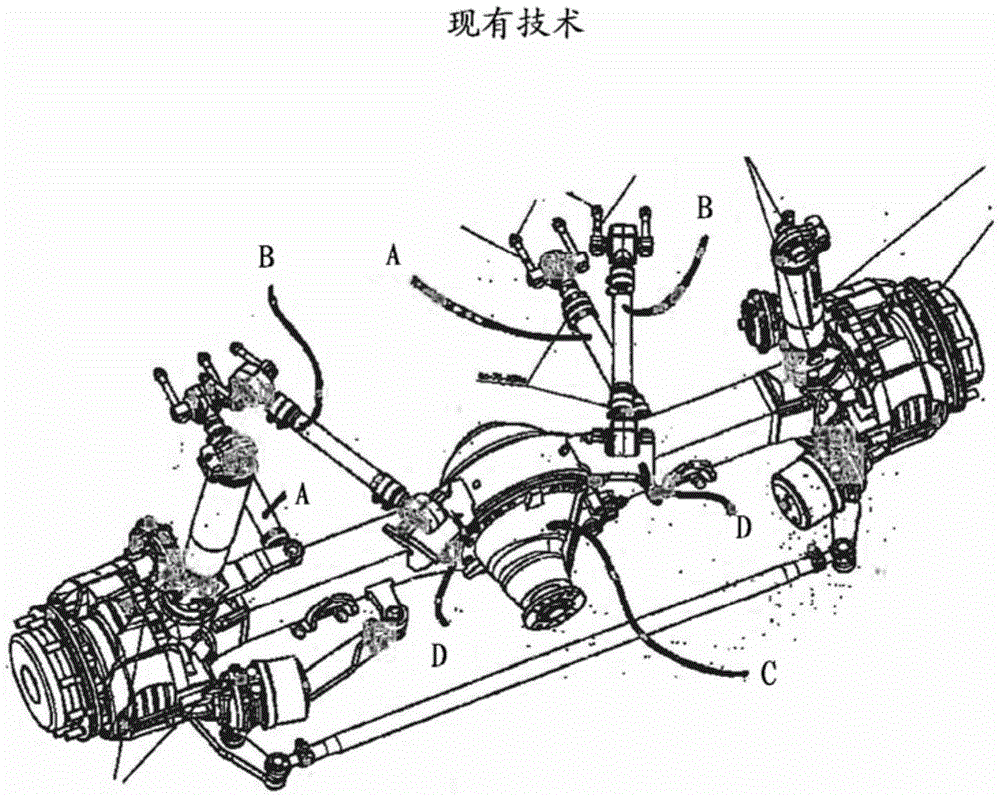

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

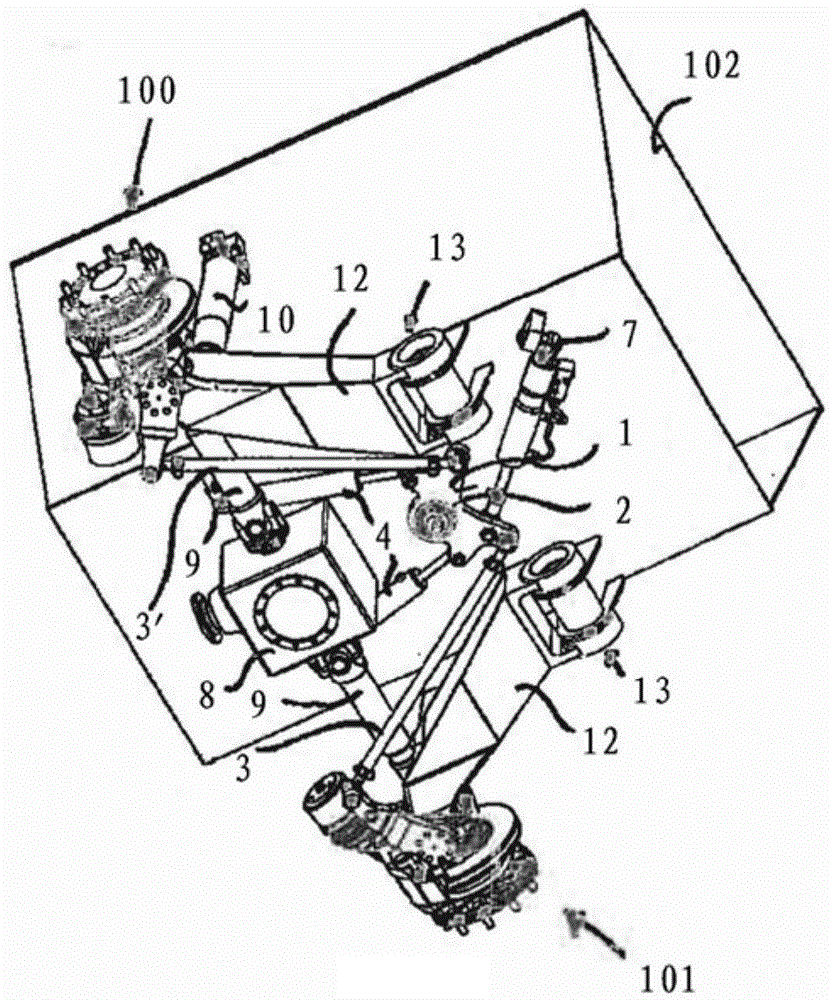

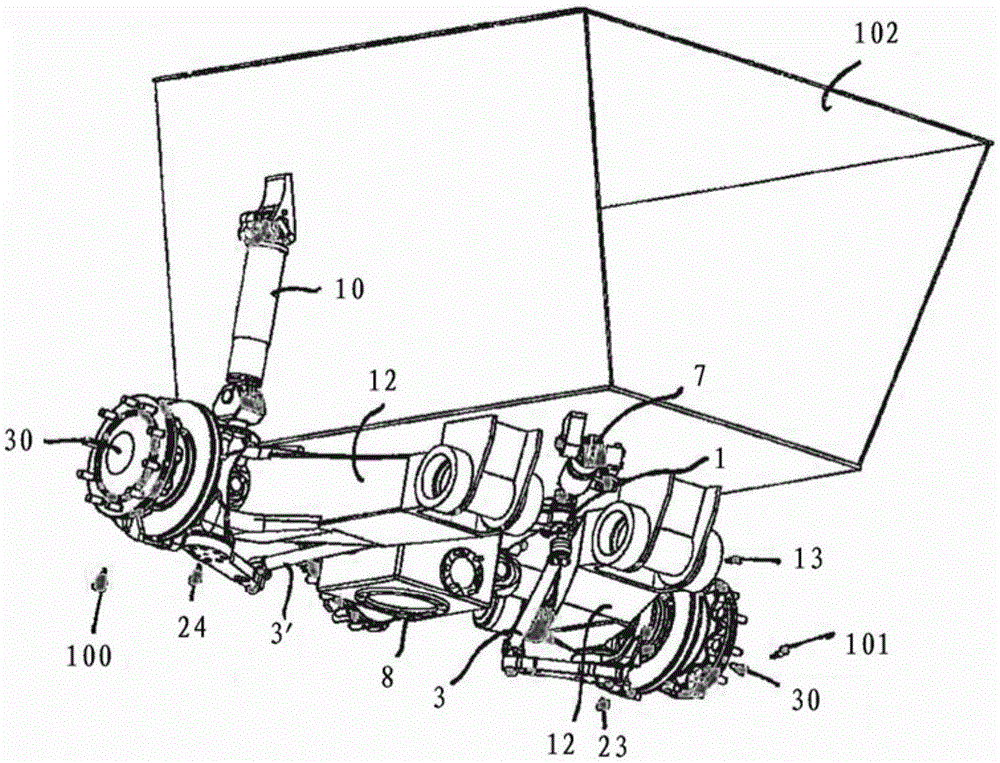

[0040] Figures 1 to 4 A first embodiment of a wheel suspension according to the invention is shown. compared to Figures 1 to 4 An example of the structure with a slight modification in the Image 6 and shown in 7 and 8. Identical components are provided with the same reference symbols in the figures.

[0041] The wheel suspension is formed as two independent single-wheel suspensions in the form of swing-arm axles (Schwingenachsen). Each wheel side 100 , 101 is supported elastically via a pivot arm 12 on a vehicle frame 102 about a horizontal pivot axis oriented transversely to the direction of travel. The wheel sides 100 , 101 are supported via steering knuckles 23 , 24 rotatably about vertical axes of rotation on the swing arm tip. The actuation of the swivel bearings on the wheel sides 100, 101 takes place by means of tie rod arms 20, 21 which are articulatedly connected to the individual tie rods 3, 3'. Both tie rods 3 , 3 ′ are hingedly mounted on a central reversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com