Thin-film transistor structure

A thin film transistor and semiconductor technology, applied in transistors, semiconductor devices, electrical components, etc., can solve problems such as limiting the current conductivity of components, low carrier mobility, and high resistivity of amorphous silicon semiconductor layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable the examiner to have a further understanding and understanding of the features and achieved effects of the present invention, the following examples and accompanying drawings are attached herewith:

[0026] One of the characteristics of the present invention is that: in view of the increasing demand for the driving performance of the transistor and the miniaturization of the circuit layout by the structure of the thin film transistor, the present invention proposes a thin film transistor structure to increase the on-current to improve the driving performance and optimize circuit layout area, etc.

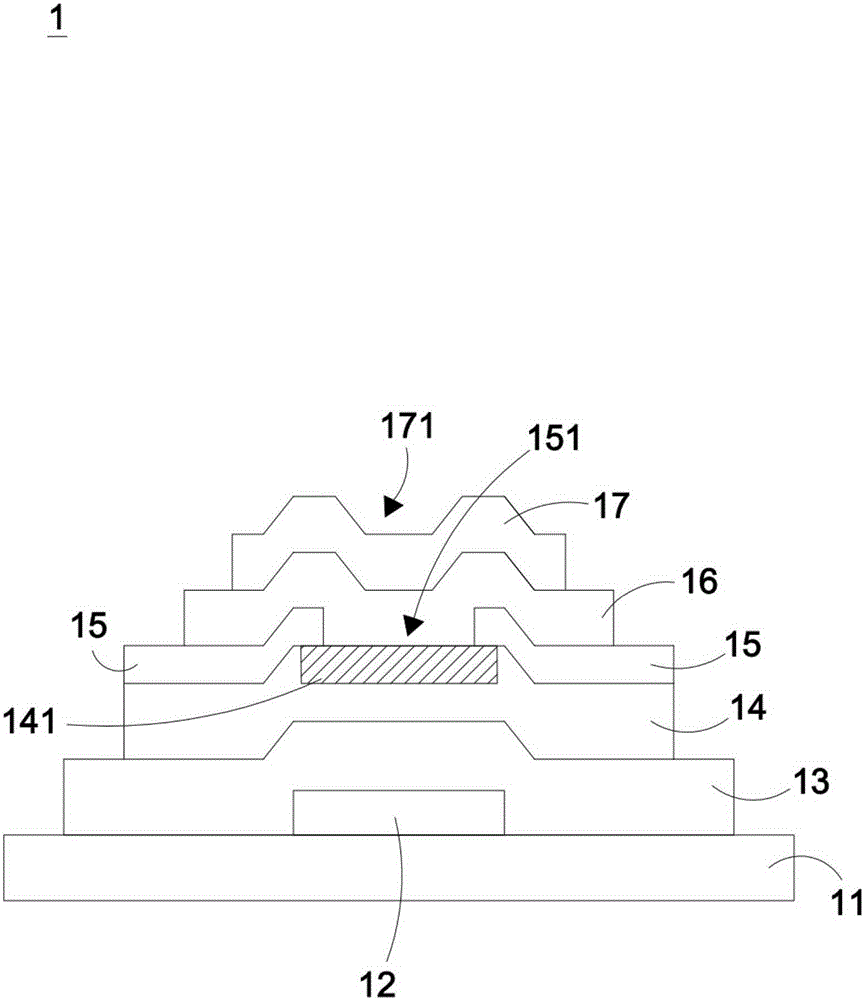

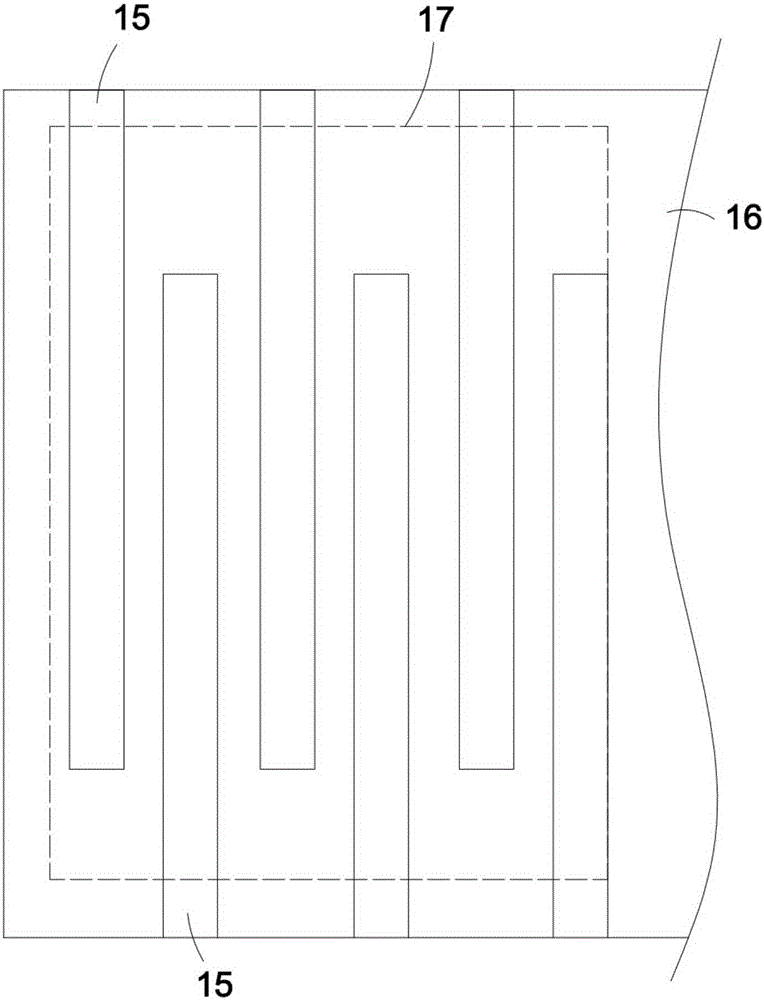

[0027] Such as Figure 1A Shown is a schematic structural diagram of the first embodiment of the present invention. As shown in the figure, it illustrates the components of this embodiment and their connection relationship. This embodiment is a thin film transistor structure 1, which includes a substrate 11, a first metal layer 12, a first buffer layer 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com